On-line monitoring system for feed quantity of combine harvester and monitoring method thereof

A combine harvester and monitoring system technology, applied to harvesters, weighing, cutters, etc., can solve the problems of inaccurate measurement, incapable of real-time monitoring of feeding amount, etc., and achieve improved work efficiency, reliable data, and convenient and reliable installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

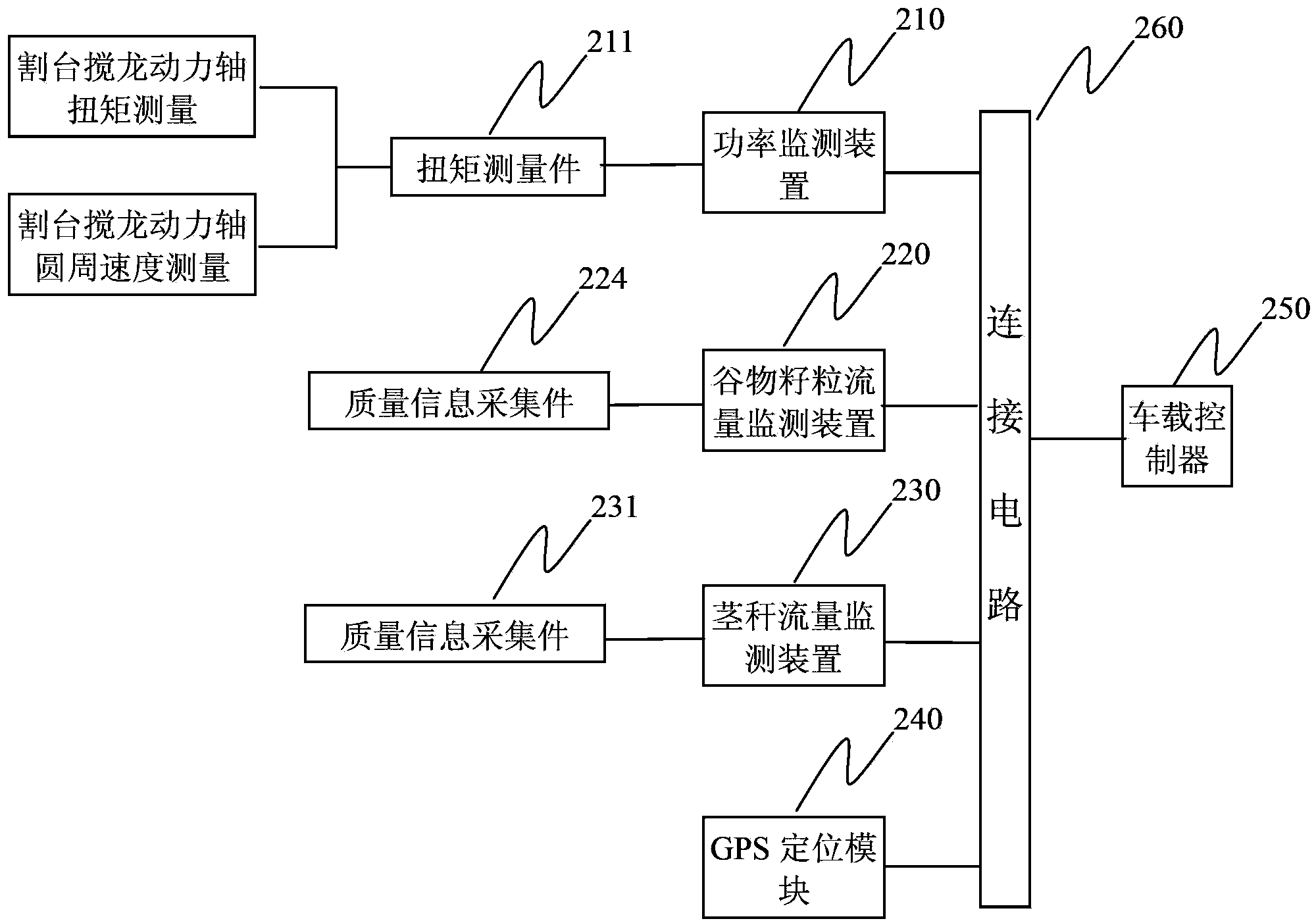

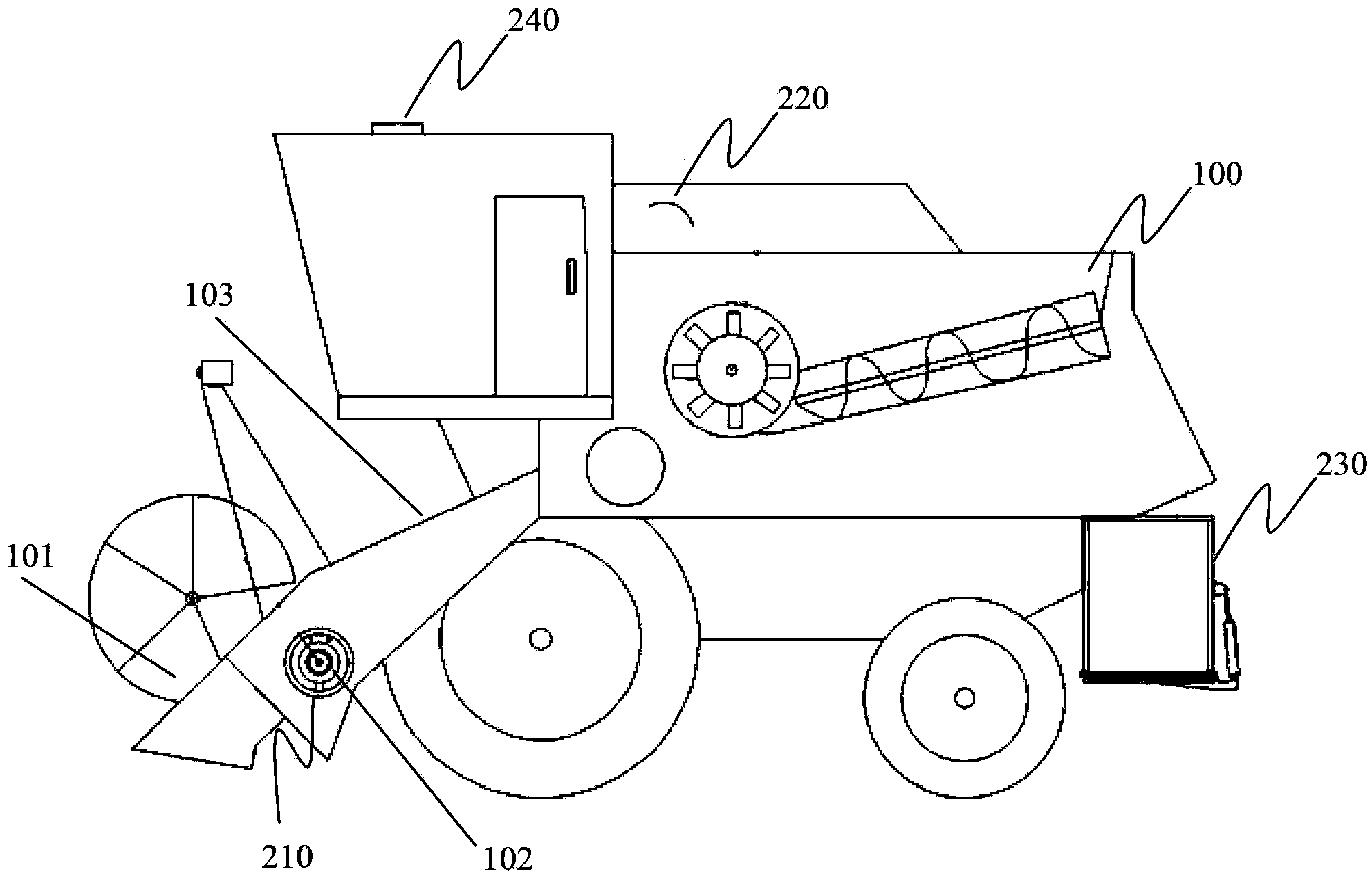

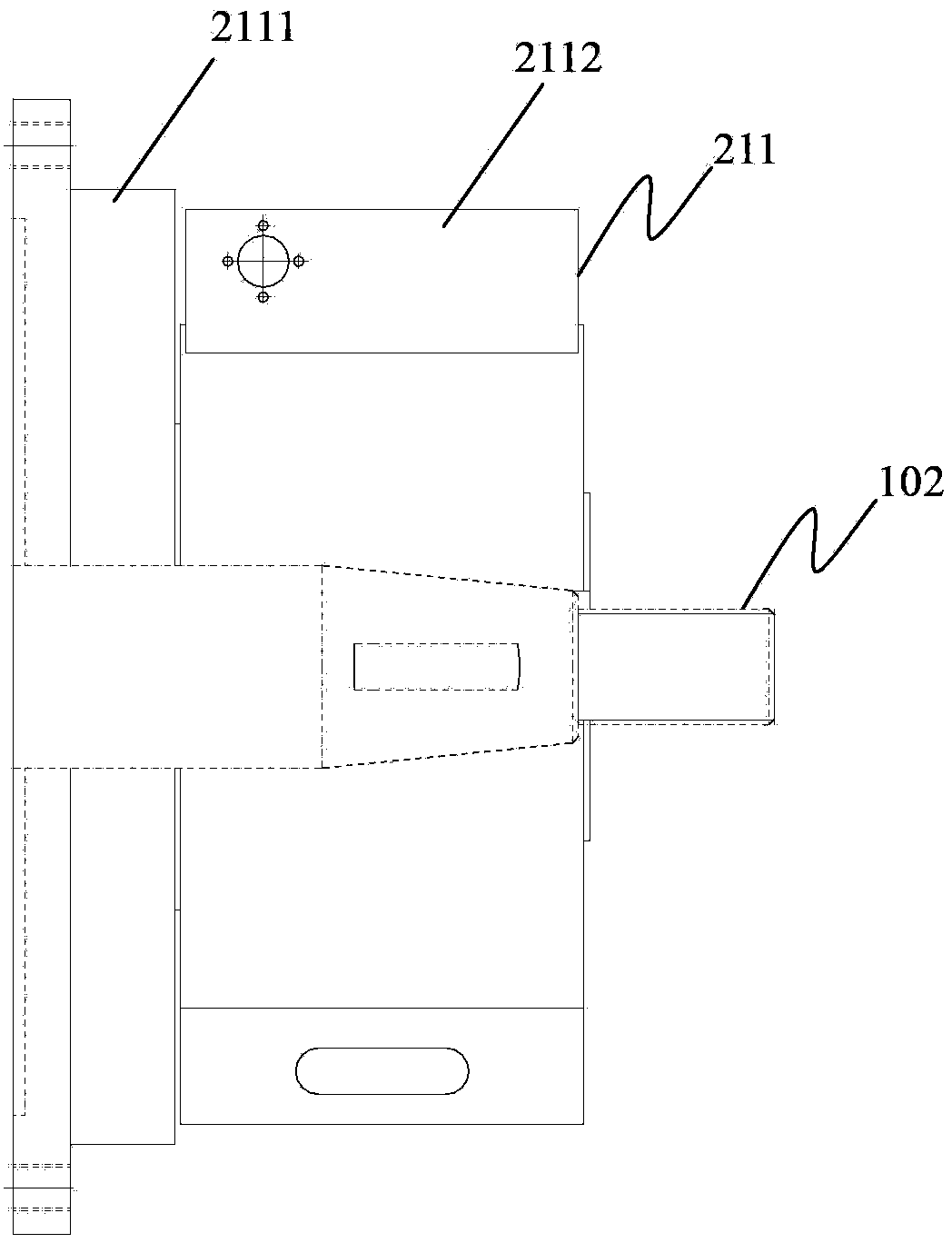

[0066] The purpose of the on-line monitoring system for the feeding amount of the rice-wheat combine harvester of the present invention is to monitor the feeding amount of the rice-wheat combine harvester on-line, and make its measurement quantitative, and solve the problem that the existing technology cannot monitor in real time and qualitative measurement leads to measurement inaccuracies etc. This invention is easy to install, easy to develop in batches, and has high online measurement accuracy. It can guide the driver to feed the amount during the harvesting process, prevent the occurrence of clogging faults, enable the harvester to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com