Leather shoes, equipment for polishing leather lines of leather shoes and leather shoe sewing method

A technology for leather shoes and equipment, which is applied to the structure of the adhesive part, the sewing bag of the leather shoes, and the equipment fields of the leather edge can solve the problems of high cost and high cost of the leather shoes, and achieve the effect of reducing the dosage and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

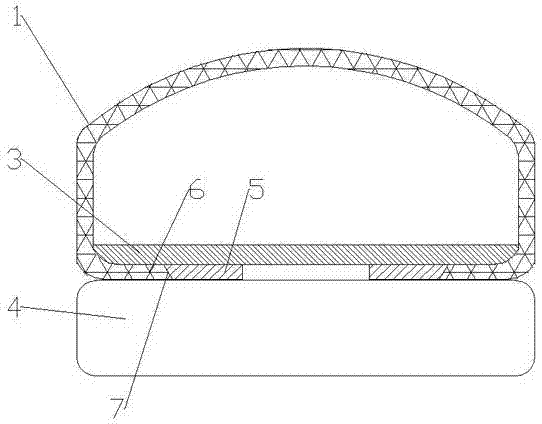

[0010] refer to figure 1 As shown, the leather shoes provided by the present invention include a leather upper 1 and a sole, and the sole includes a midsole 3 and an outsole 4. The leather upper 1 is bent inward and is located between the midsole 3 and the outsole. The inwardly bent portion of the leather upper 1 is bonded to the outsole 4, and the inwardly bent portion of the leather upper 1 includes a selvedge 6 and a leather edge 6 integrated with the leather upper 1, and the leather edge 6 is connected to the leather upper 1. The bonding part of the outsole 4 is polished into a rough surface, and the leather edge 6 is connected with the selvedge 5 and bonded together with the outsole 4 . In this embodiment, the edge of the leather edge 6 is polished with an obliquely distributed end surface 7, and the selvedge 5 is stitched with the leather edge end surface 7. The area of the oblique end surface 7 is larger than the vertical end surface, which increases the stitching are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com