Patents

Literature

61results about How to "Does not affect firmness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

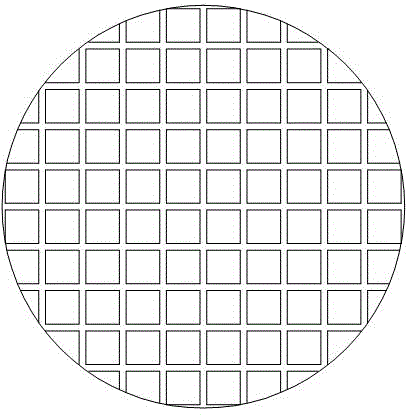

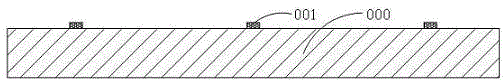

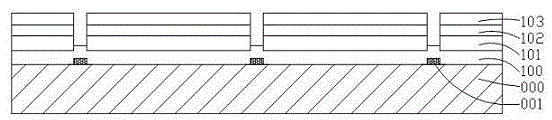

Vertical structure light emitting diode chip with low cost and preparation method thereof

ActiveCN103560193ADoes not affect firmnessReduce manufacturing costSemiconductor devicesPhysical chemistryAlloy

Owner:南昌硅基半导体科技有限公司 +1

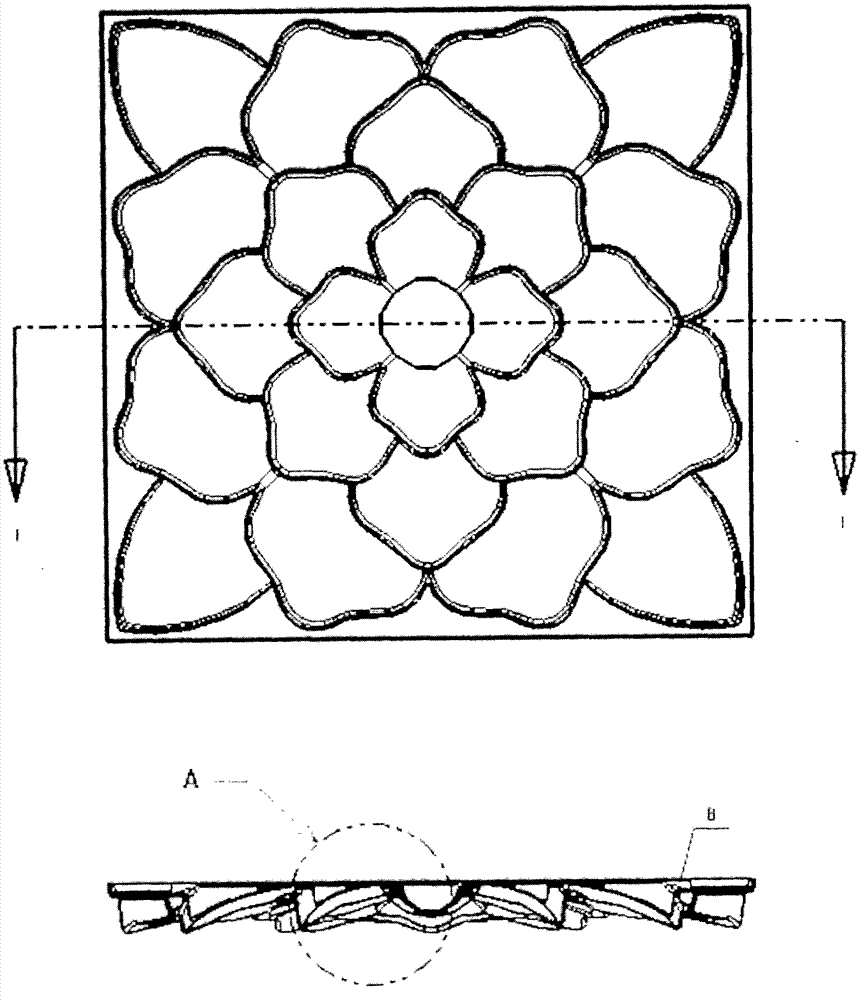

Filigree enamel silverware and manufacturing method thereof

PendingCN106240217AWeld firmlyDoes not affect appearanceDecorative surface effectsSpecial ornamental structuresMaterials sciencePigment

The invention relates to the technical field of silverware manufacturing processes, in particular to filigree enamel silverware and a manufacturing method thereof. The manufacturing method for the silverware comprises the following steps in sequence: preparing a blank, whisking, filigreeing, welding, dispensing a blue pigment, and grinding the blue pigment; the step of dispensing the blue pigment comprises the following processes: filling a pattern which is formed by silver wires on the surface of a silver blank which is welded in the step (4) with glazes, then performing high-temperature sintering, namely, sintering a low-temperature glaze for 3 to 6 minutes at the temperature of 710 to 790 DEG C, sintering a high-temperature glaze for 2 to 5 minutes at the temperature of 780 to 830 DEG C, and repeating the processes of filling the glazes and sintering for 3 to 4 times. The filigree enamel silverware provided by the invention is attractive in appearance and colour, long in storage time and wide in spreading degree; colours are rich and are not single. The manufacturing method for the filigree enamel silverware provided by the invention is easy and quick to operate, and is suitable for industrial popularization.

Owner:河南梦祥纯银制品有限公司

Sewing method for realizing molding of upper by adopting sewing machine

The invention discloses a sewing method for realizing the molding of an upper by adopting a sewing machine. The sewing method comprises the following steps of turning a front upper surrounding and an upper cover, turning a shoe body and a shoe-body ornament, sewing a rear upper, coating an all-purpose adhesive on the rear upper and the shoe body, pasting a reinforcer, turning a rear-upper ornament, turning the shoe body and an upper shoe-body ornament, sewing the rear upper with a front upper, sewing a shoe tongue, reversely turning the rear upper and a neckline lining, coating the all-purpose adhesive on a front upper lining and a middle upper lining, turning and combining an upper lining and front and middle shoe upper vamps, turning the shoe tongue and a vamp, pasting a neckline foamed vamp, pasting a front liner and a rear liner, overturning a neckline, and manufacturing shoe eyelets. By the method, the upper is sewn through a plurality of parts, and the upper can be locally replaced in production on the premise that the integral fastness of the upper is not influenced, so that the waste of the upper is prevented from occurring, and the problems that an existing traditional upper is integrally molded, the integral upper only can be discarded as a waste when partial position defects occur, so that serious waste is caused are solved.

Owner:CHENGDU CAMEIDO SHOES

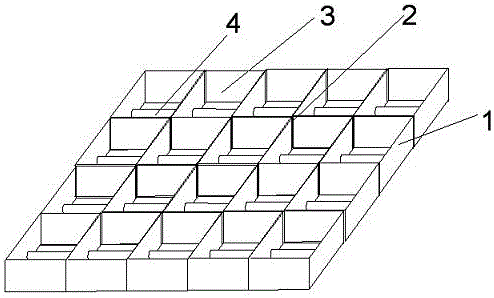

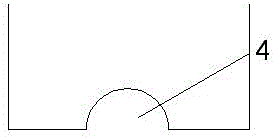

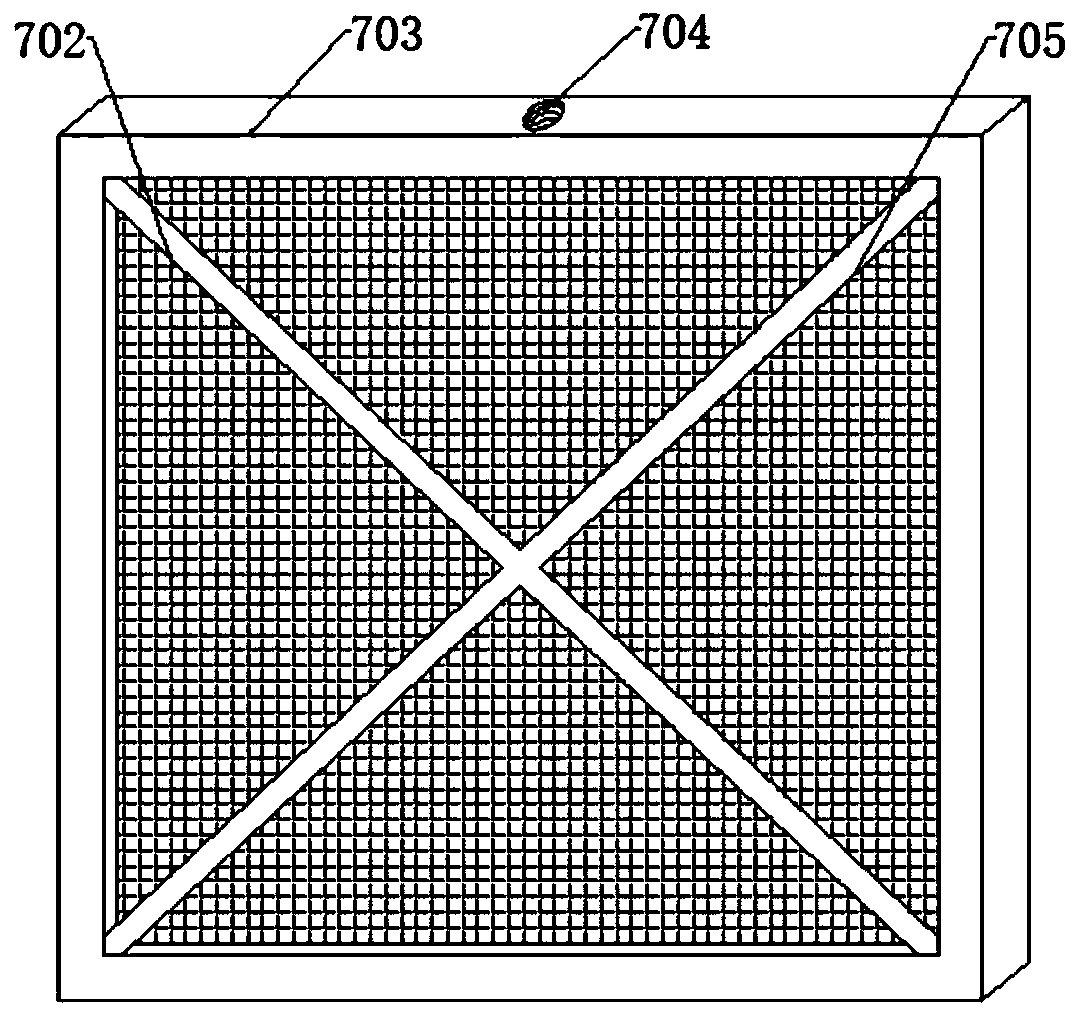

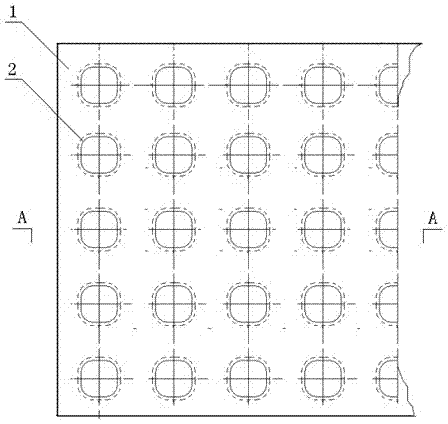

Pouring mold and pouring using method for plate type concrete steel bar positioning blocks

InactiveCN106079049AMake sure the sizeAvoid swiping up and downMould auxillary partsBuilding reinforcementsRebarMaterials science

The invention discloses a pouring mold for plate type concrete steel bar positioning blocks. The pouring mold is used for pouring the positioning blocks for plate type concrete steel bars and is of a cubic structure, a cubic cavity is formed in the pouring mold, multiple crisscross partition plates are arranged in the cavity to divide the cavity into multiple pouring grooves with the same size, the bottom face of each pouring groove is transversely provided with a semi-cylindrical convex block, and the bottom faces of the two sides of each convex block are provided with multiple circular holes. According to the pouring mold for the plate type concrete steel bar positioning blocks, the positioning blocks for positioning the steel bars in plate type concrete are poured through the mold, the positioning blocks can be attached and fixed to the steel bars, the color and material of the positioning blocks are same as those of the concrete, and therefore attractiveness and stability which are achieved after mold plates are disassembled are not affected.

Owner:IANGSU COLLEGE OF ENG & TECH

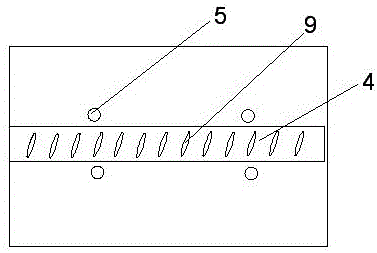

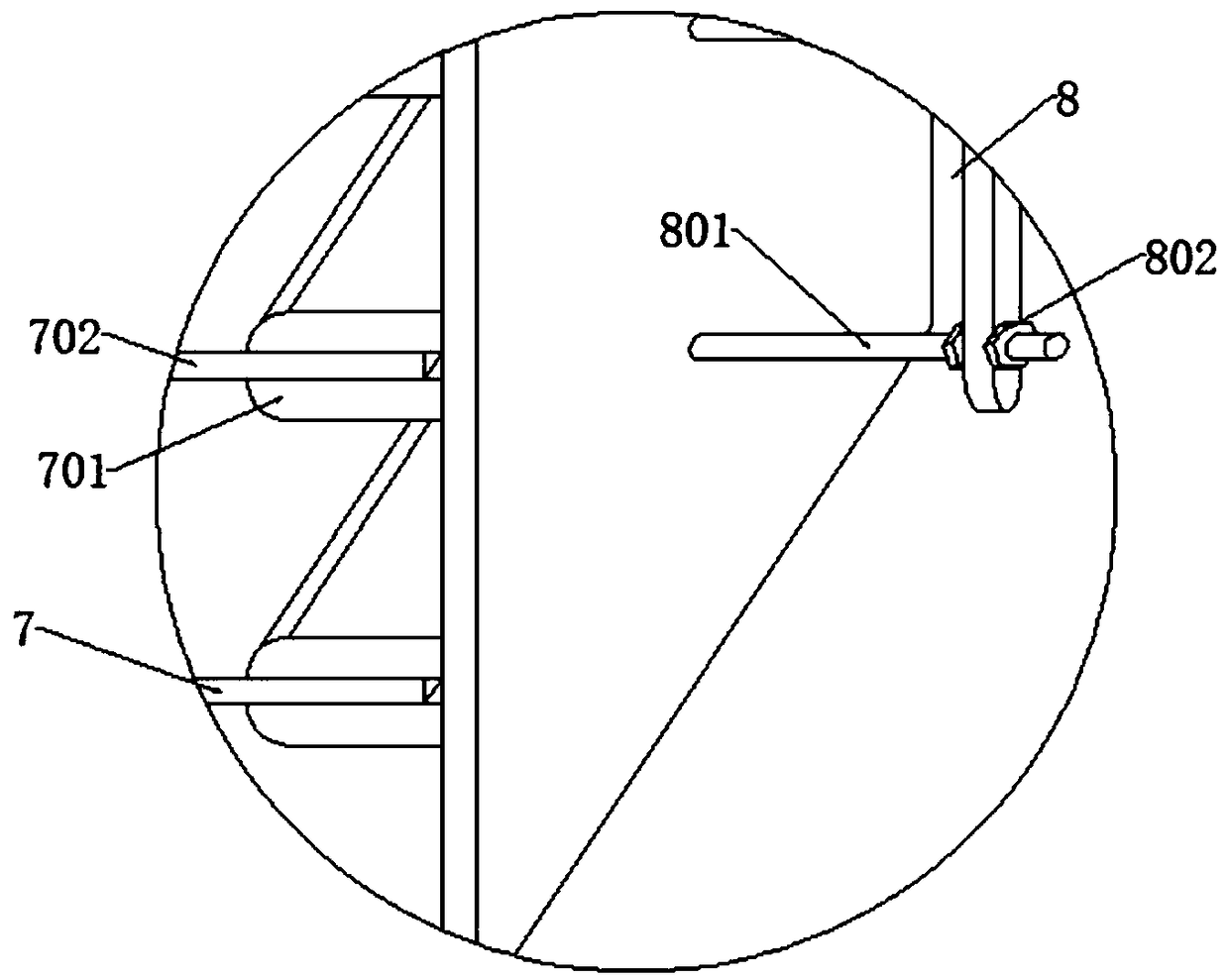

Rack for concrete mixer

InactiveCN104589499ADoes not affect firmnessImprove stabilityCement mixing apparatusEngineeringUltimate tensile strength

The invention provides a rack for a concrete mixer, and belongs to the technical field of machinery, and the rack can be used for solving the problem that the rack of an existing concrete mixer is not sufficient in strength. According to the concrete mixer, the concrete mixer comprises a feeding hopper and a mixing tube, and the rack comprises a mounting rack, wherein a support is fixedly connected on the mounting rack; a triangular reinforcing plate I is fixedly connected at the corner of the support; a mounting plate is fixedly connected to the top of the support; two ends of the mounting plate are respectively fixedly connected with one slide rail, and the other end of each slide rail is fixedly connected with another frame of the mounting rack; the feeding hopper is arranged on the slide rails; a triangular reinforcing plate II and a rectangular reinforcing plate III are arranged in a gap between the mounting plate and the slide rails; the mixing tube is fixedly connected to the other two frames in four frames of the mounting rack; guiding tubes which are arranged along the vertical direction are fixedly connected to four corners of the mounting rack respectively; and a pin is inserted in each guiding tube. The rack for the concrete mixer has the advantage of high firm degree.

Owner:张鑫杰

Gypsum-based pouring mortar capable of preventing alkaline return and preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to a gypsum-based pouring mortar capable of preventing alkaline return and a preparation method thereof. The gypsum-based pouring mortar has the advantages that a water retention agent and an alkaline inhibitor are added into the gypsum to improve, and the microcrystalline cellulose is jointly used with amixed water retention agent, so that the synergistic function is realized, the usage amount is reduced, and the cost is reduced; by adopting the mixed water retention agent and the alkaline inhibitor,the alkalization of the gypsum is inhibited, and the strength of the gypsum is improved; the weight is light, the fireproof and flame-retardant properties are realized, and the appearance of a wall surface is attractive.

Owner:深圳摩盾环保新材料有限公司

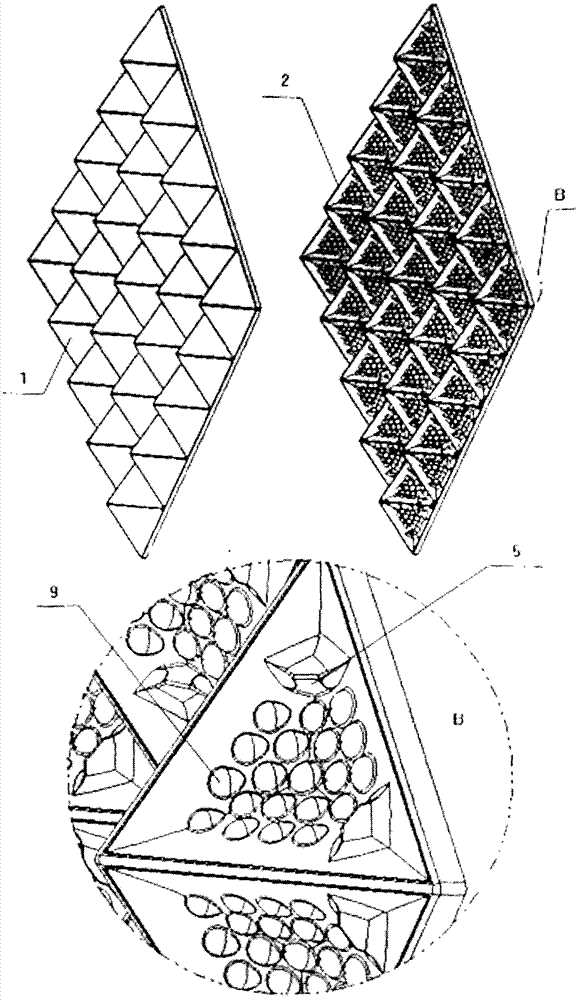

LED light source, luminous ornament and illumination decorative lighting utilizing variable optical module to emit light

InactiveCN103363330AGood effectImprove reliabilityLighting heating/cooling arrangementsSpecial ornamental structuresOptical ModuleEffect light

The invention discloses an LED light source, a luminous ornament and an illumination decorative lighting utilizing a variable optical module to emit light. The variable optical module is composed of an inner shell, an outer shell and transparent media poured in a plurality of cavities between the inner shell and the outer shell. Usually, a layer of reflective film is arranged on the surface of the inner shell. The inner shell is provided with a plurality of small planes corresponding to luminous faces of an LED. The LED is pasted on the small planes on the inner side of the inner shell through transparent adhesive tape, light holes are formed in positions, corresponding to the LED, of the reflective film, and circuits and structural members of the LED are arrayed and fixed on the inner side of the inner shell. Light emitted by the LED forms various light effects and light shapes on the variable optical module after the light is subjected to optical variation. The LED optical variation light source can be made into various shapes like planes, curved faces, embossments and sculptures, and emit light wholly, and also can emit light in partial artistic shapes and artistic patterns. The LED optical variation light source can be used as a light source on the decorative lighting and can also be directly made into the luminous ornament or the illumination decorative lighting.

Owner:徐建国

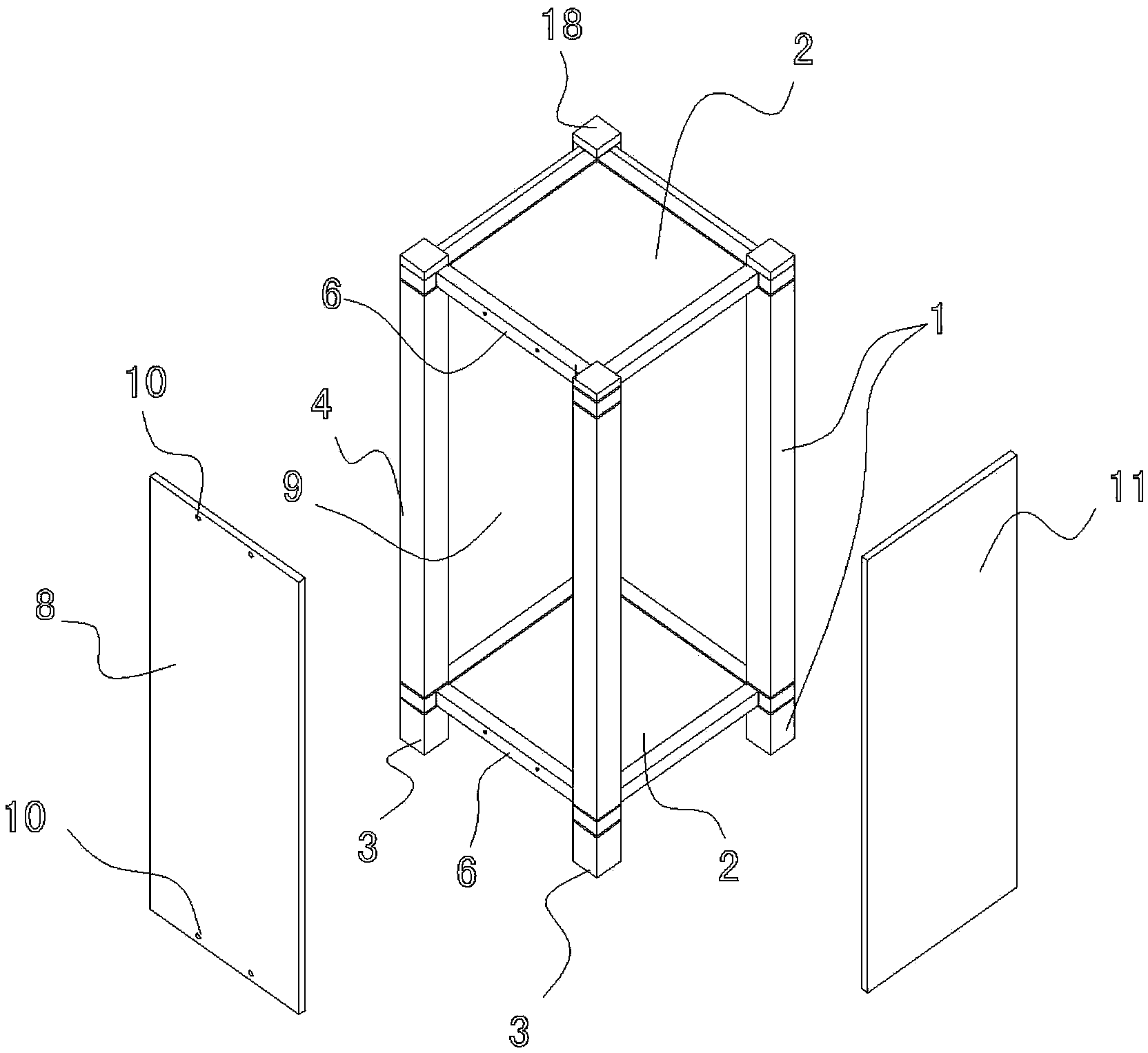

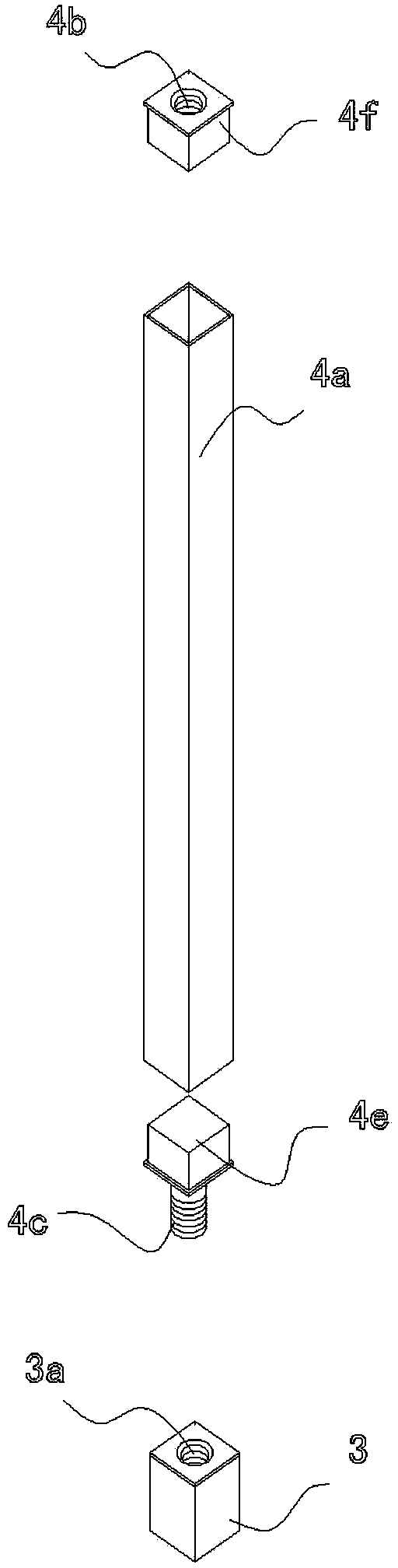

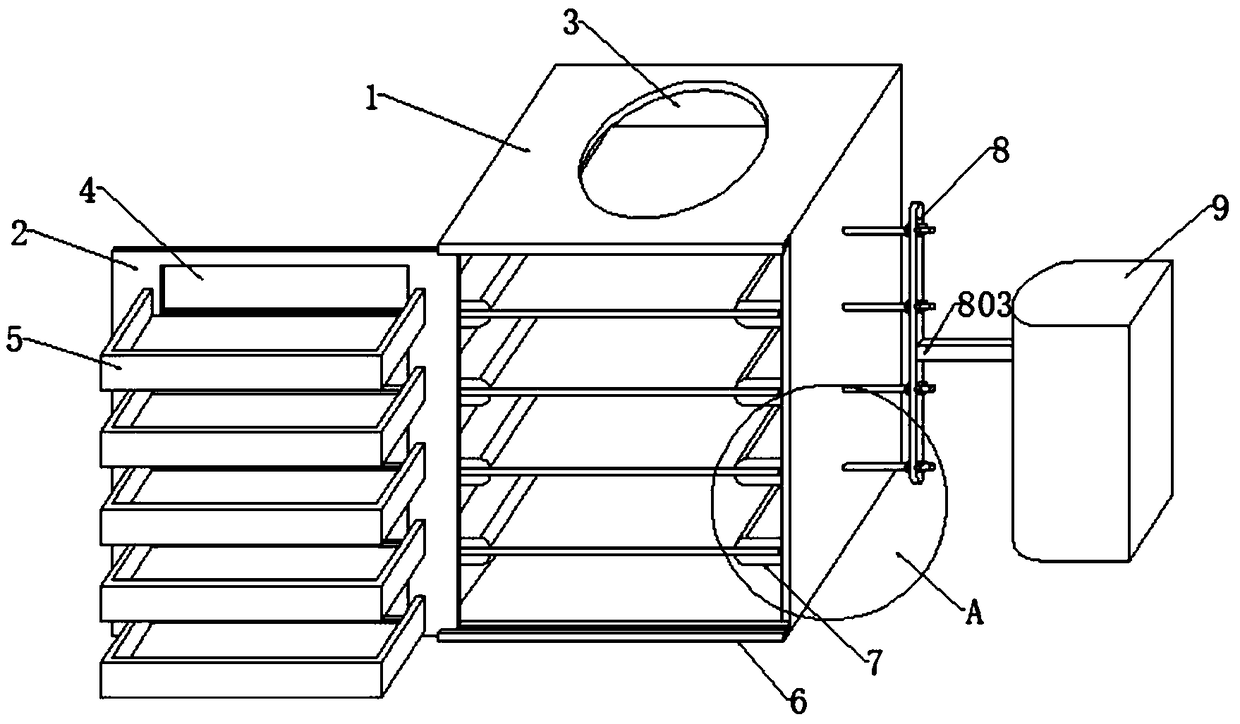

Cabinet convenient to assemble

Owner:胡波 +1

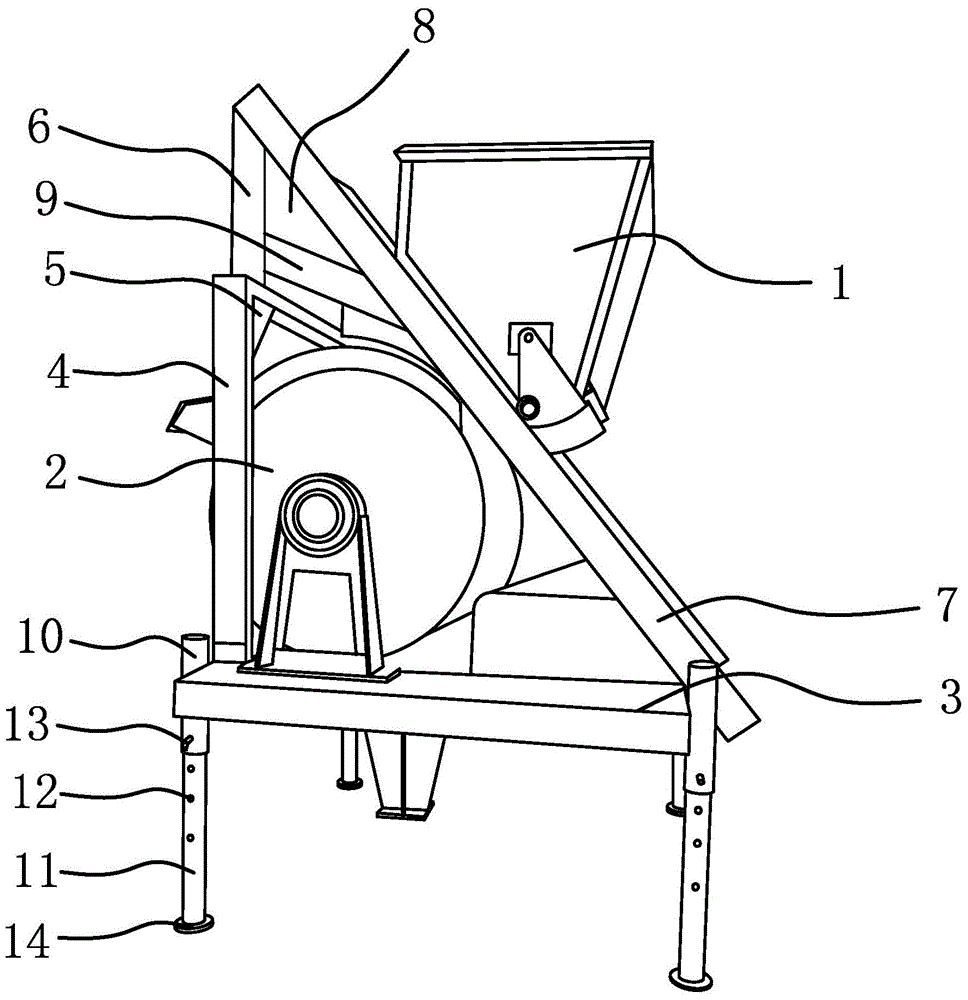

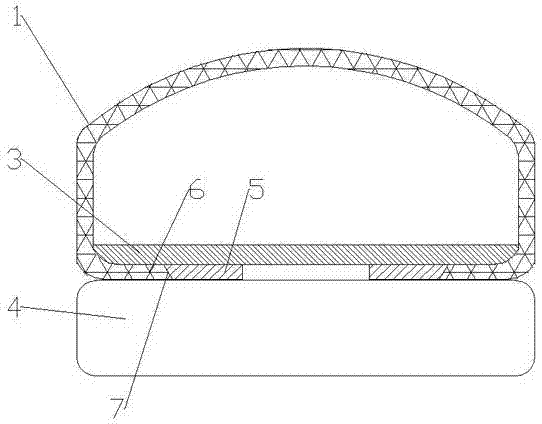

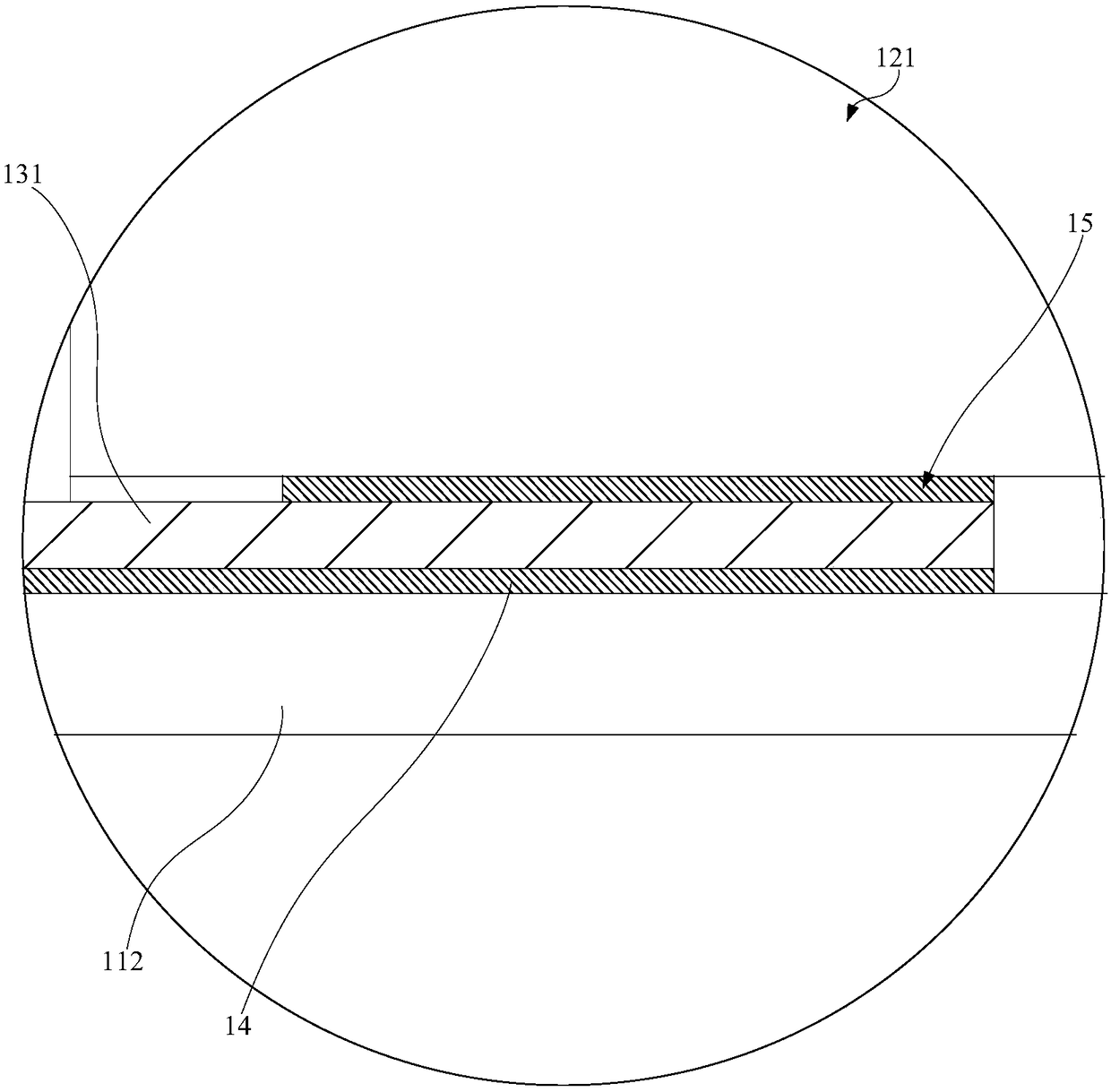

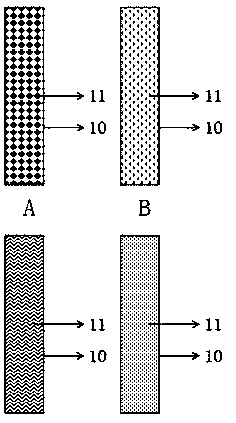

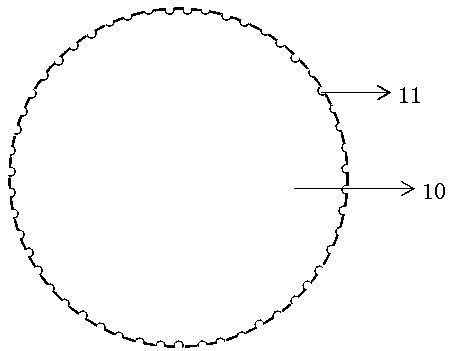

Leather shoes, equipment for polishing leather lines of leather shoes and leather shoe sewing method

ActiveCN104323535AReduce dosageDoes not affect firmnessShoemaking devicesUpperRough surfaceEngineering

The invention discloses a pair of leather shoes. Each leather shoe comprises a leather vamp and a sole, wherein the sole comprises an insole and an outsole; the leather vamp is inwards bent and is positioned between the insole and the outsole; the inward bending part of the leather vamp is bonded with the outsole. The leather shoes are characterized in that the inward bending part of each leather vamp comprises a cloth line and a leather line combined with the leather vamp into a whole, the bonding positions of the leather lines and the outsole are polished into a rough surface, and the leather lines and the cloth lines are connected and are jointly bonded with the outsoles. The invention also discloses equipment for polishing the leather lines of the leather shoes, and a leather shoe sewing method. The structure of the leather shoes and the sewing method are favorable for saving of leather materials, and meanwhile, the bonding firmness of the vamp and the outsole after the leather shoes are sewn is not affected.

Owner:ZHEJIANG RED DRAGONFLY FOOTWEAR

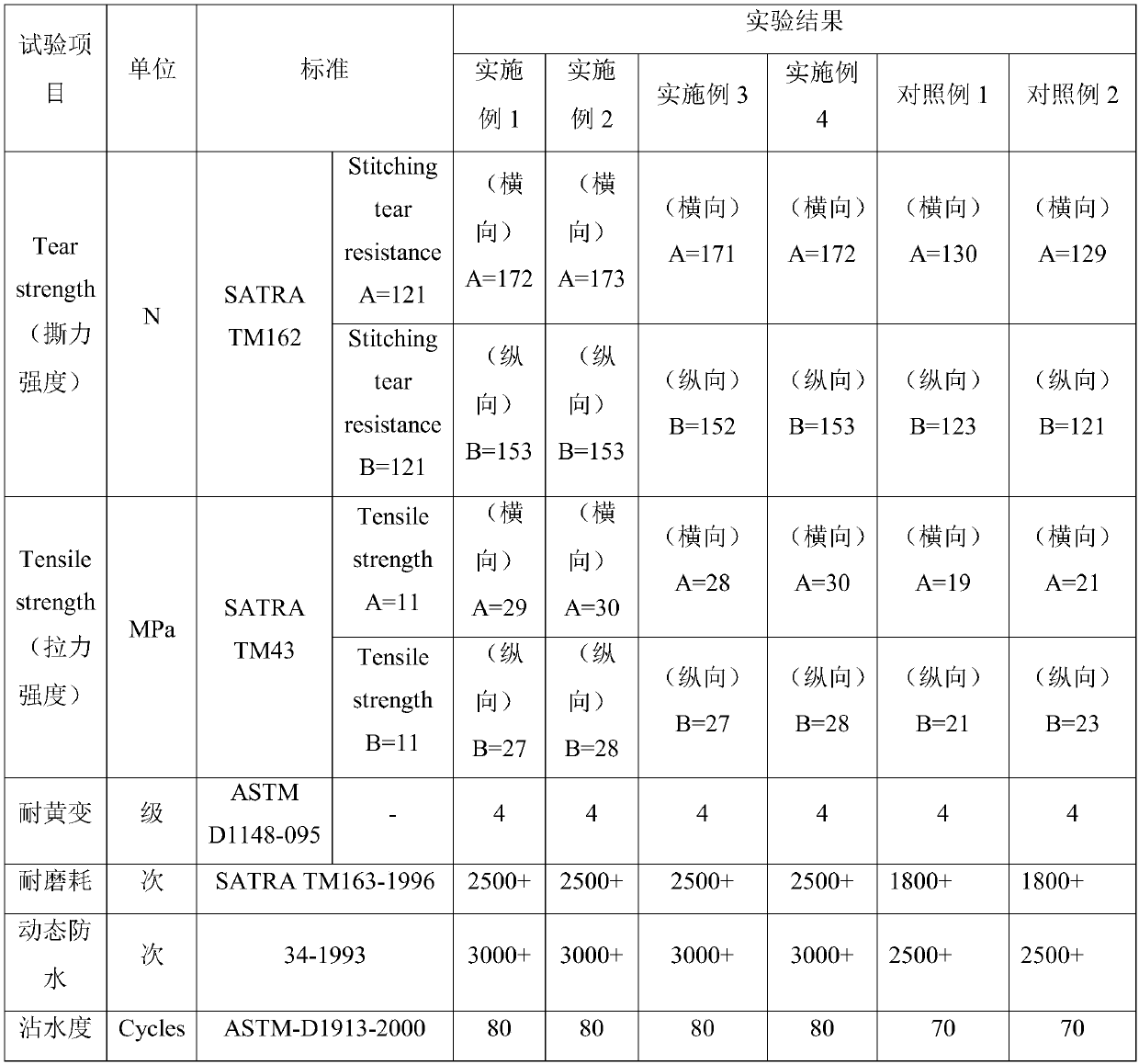

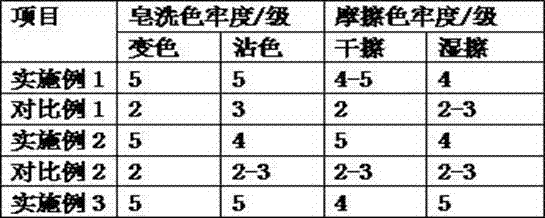

Preparation method for environmentally-friendly waterproof mercerized suede leather

ActiveCN109536649AGood light fastnessGood lubricationLeather impregnationChemistryEnvironmentally friendly

The invention discloses a preparation method for environmentally-friendly waterproof mercerized suede leather. The preparation method comprises the steps of sequentially carrying out the processes ofretanning, neutralizing, packed fat liquoring and the like. According to the preparation method, a novel environmentally-friendly material is adopted in the packed fat liquoring process and is subjected to step-by-step fat liquoring for preparation, the prepared environmentally-friendly mercerized waterproof suede leather has a good silk-like feeling and writing effect, the trimming rate of the finished leather is low, the utilization rate of the leather is high, a technical process adopts step-by-step fat liquoring, so that the material absorption is sufficient and complete, the waste discharge is reduced, and the environmental protection treatment difficulty is lowered.

Owner:FENGAN LEATHER

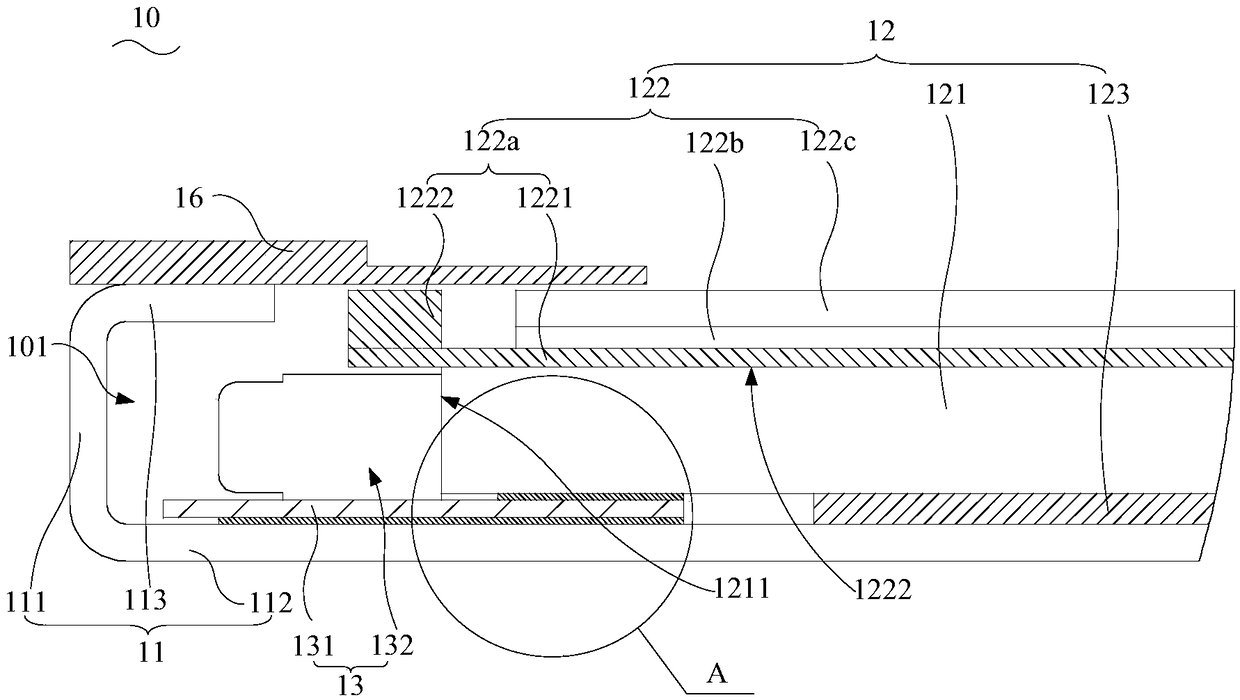

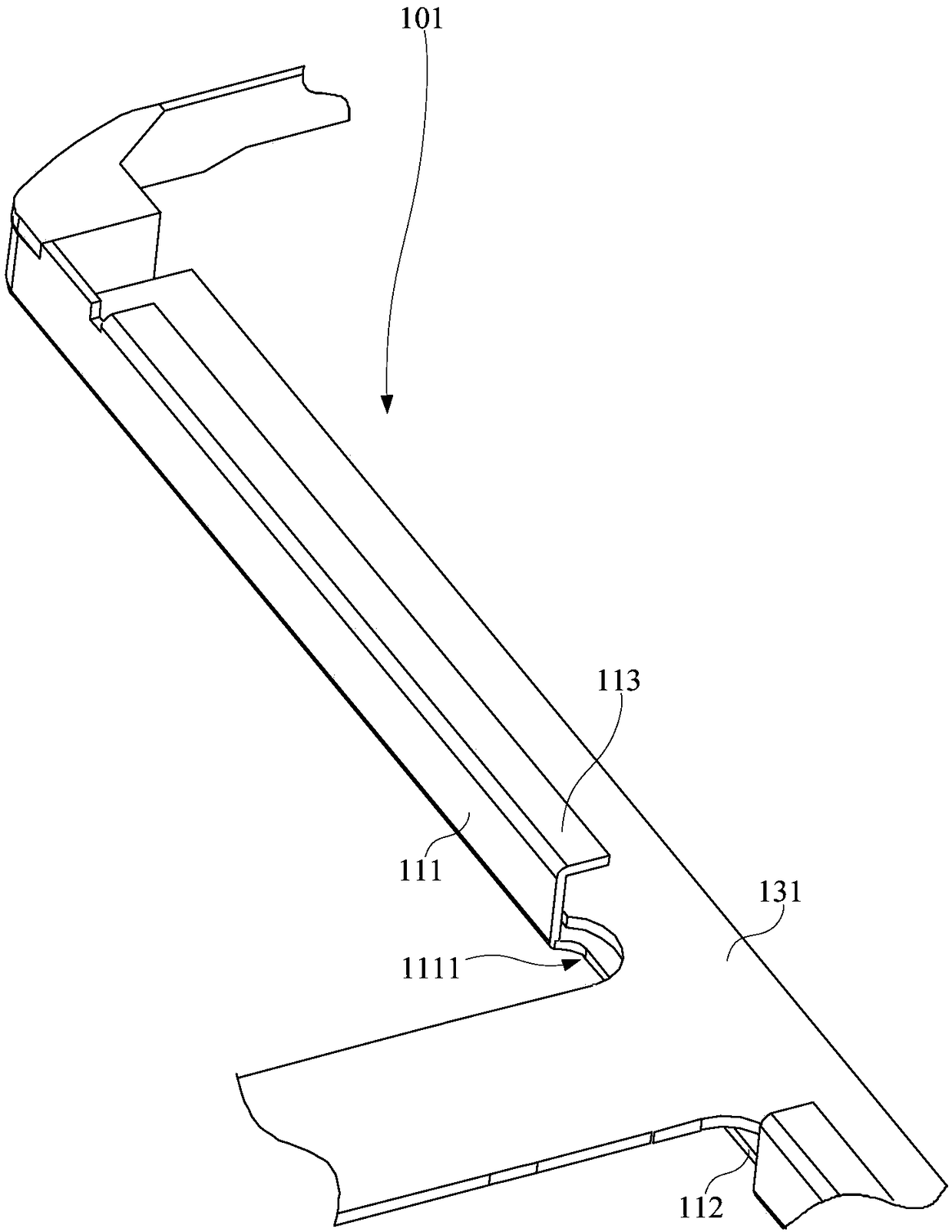

Backlight module and electronic device

PendingCN108087793ASmall footprintRealize narrowingElectric circuit arrangementsSemiconductor devices for light sourcesFlexible circuitsEngineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Method for preparing light reflecting leather

ActiveCN109609707AFully dispersedAdequate responseTanning treatmentLeather/skins/hides/pelt chemical treatment apparatusSecondary colorChemistry

The invention discloses a method for preparing light reflecting leather, and belongs to the technical field of leather. The method for preparing the light reflecting leather comprises the following steps that a leather base is put in a drum, after tempering, retanning velvet improving, neutralizing, pre-adding of ester, dyeing, ester adding, color fixing, product surface treatment and secondary treatment are sequentially treated, then the light reflecting leather is obtained, wherein secondary treatment comprises the following steps of secondary tempering, secondary adding of ester, secondarydyeing, secondary color fixing, drying and milling. The prepared light reflecting leather is high in velvet feeling and high in softness.

Owner:漳州香洲皮革有限公司

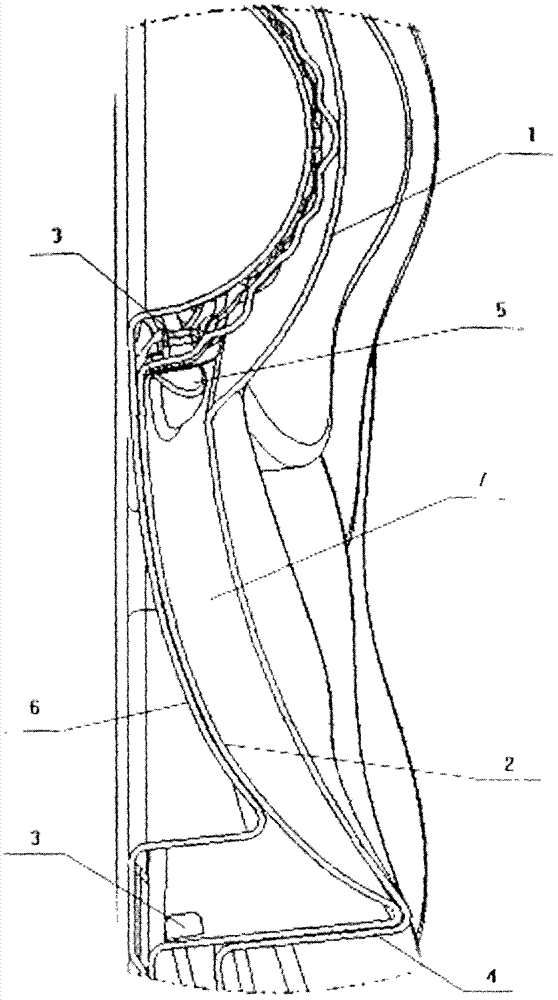

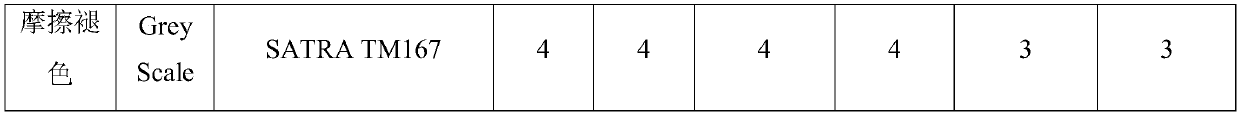

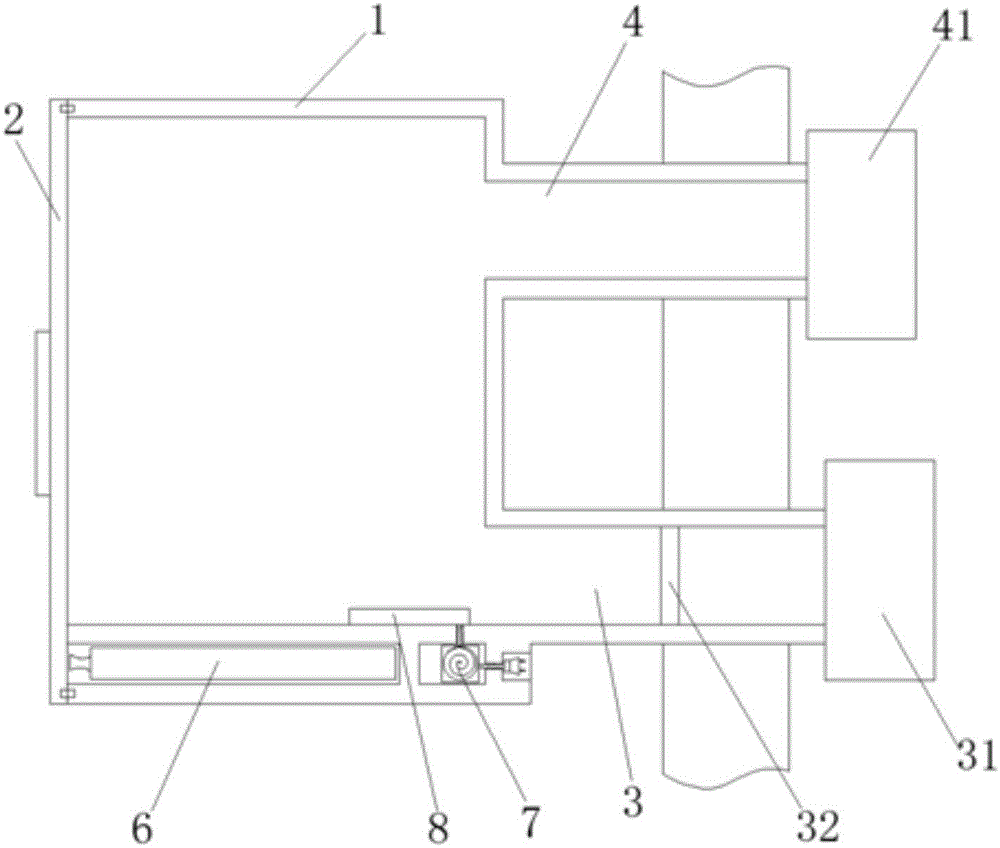

Air conditioner mounting structure for outer wall of building

InactiveCN106642413AEasy installationDoes not affect firmnessLighting and heating apparatusAir conditioning systemsRebarAgricultural engineering

The invention discloses an air conditioner mounting structure for an outer wall of a building. A shutter mounting upper rod is fixed on an upper prefabricated member; an upper rod barb is molded at the upper part of the shutter mounting upper rod and is embedded in the upper prefabricated member; a shutter mounting lower rod is fixed on a lower prefabricated member; a lower rod barb is molded at the lower part of the shutter mounting lower rod and is embedded in the lower prefabricated member; both the upper prefabricated member and the lower prefabricated member are reinforced concrete prefabricated members; the upper surface of the upper prefabricated member is a slope; an upper prefabricated member drip groove is molded in the lower surface of the upper prefabricated member; a lower prefabricated member drip groove is molded in the lower surface of the lower prefabricated member; a pipe is located on the outer wall corresponding to the space between the upper prefabricated member and the lower prefabricated member; an air conditioner outdoor unit is placed on the lower prefabricated member; and aluminium alloy shutters are mounted on the shutter mounting upper rod and the shutter mounting lower rod. According to the structure, the air conditioner accommodating place is built on the outer wall while the outer wall is built, during mounting of an air conditioner, hole punching and cavity punching are not required, the air conditioner is effort-saving to mount, and meanwhile, the firmness of the outer wall of the building is not affected.

Owner:FOSHAN HAIYUE ZHIDA TECH CO LTD

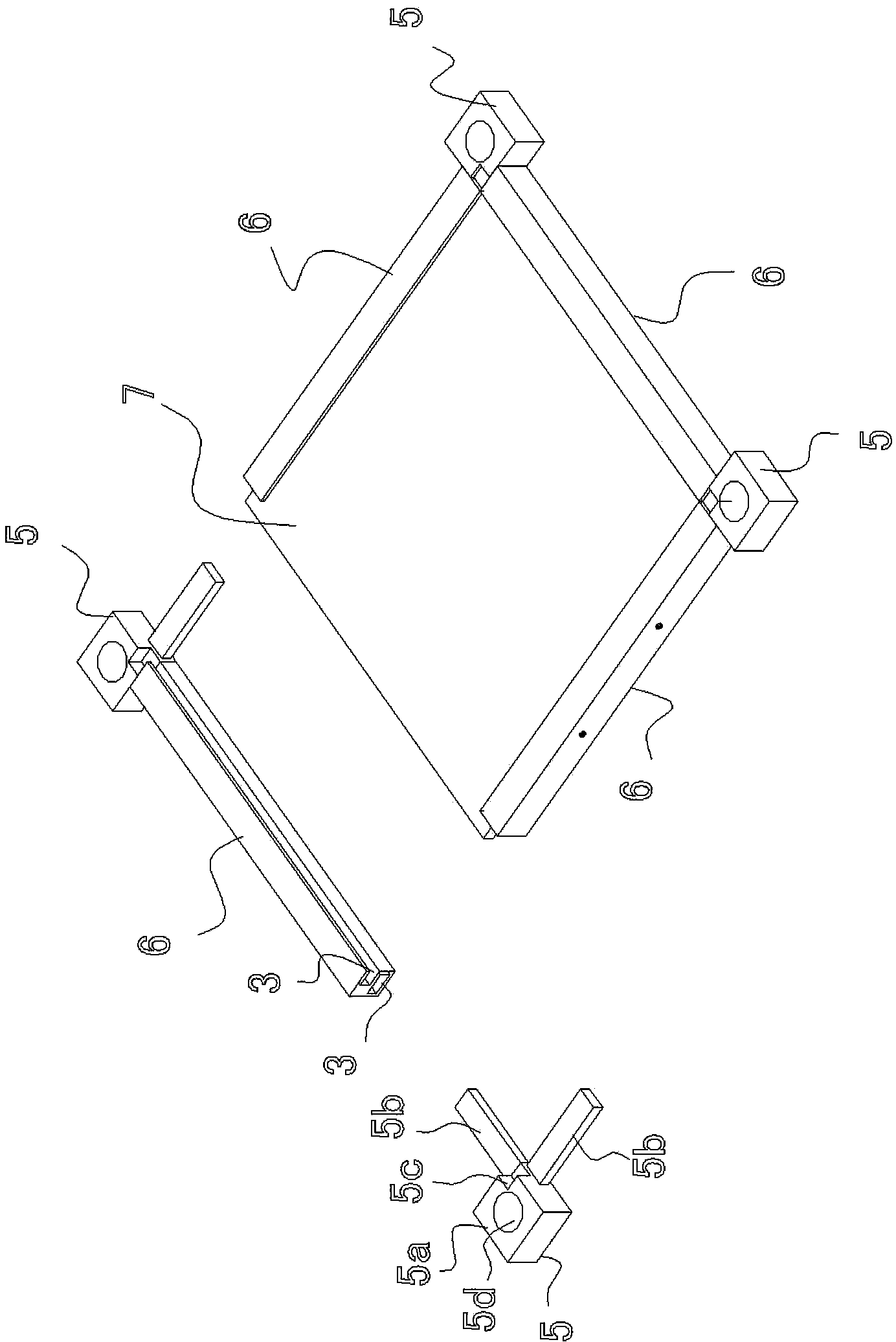

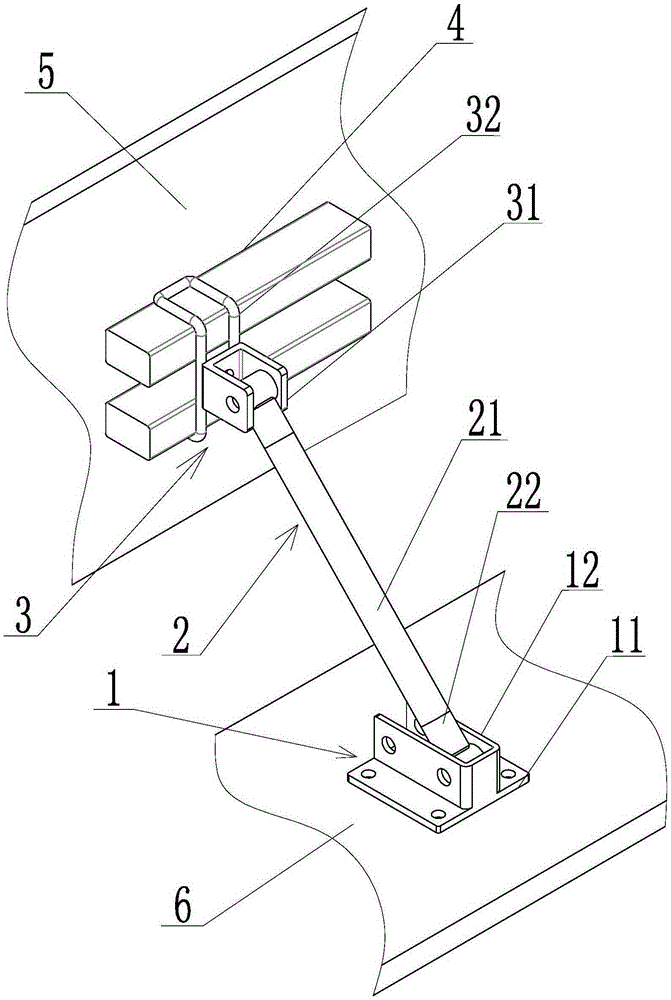

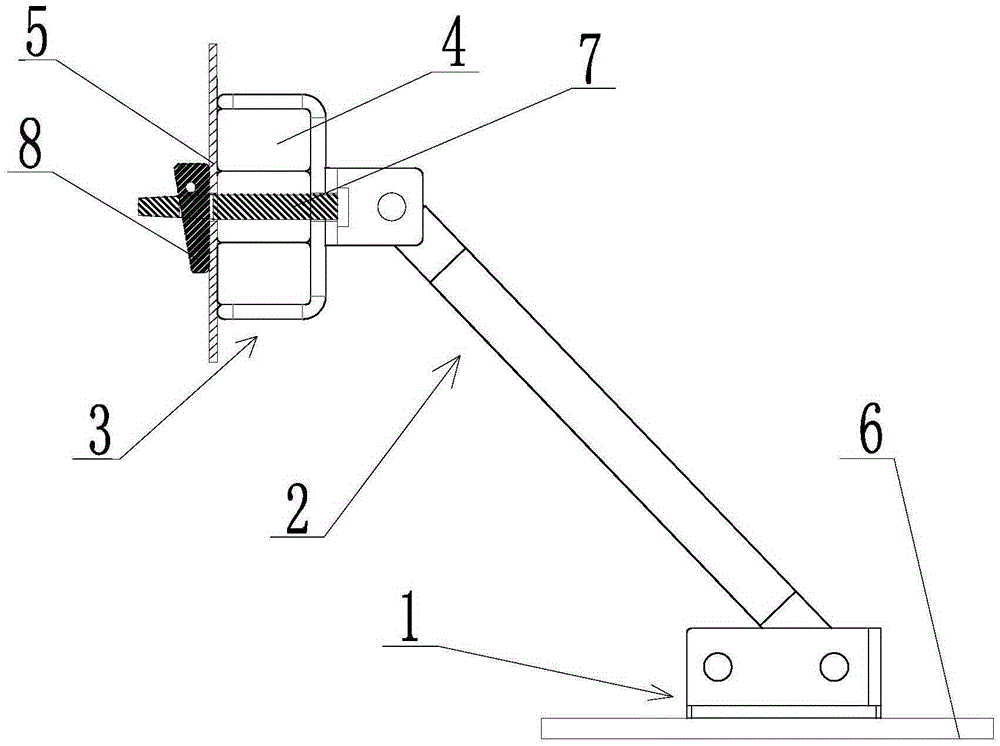

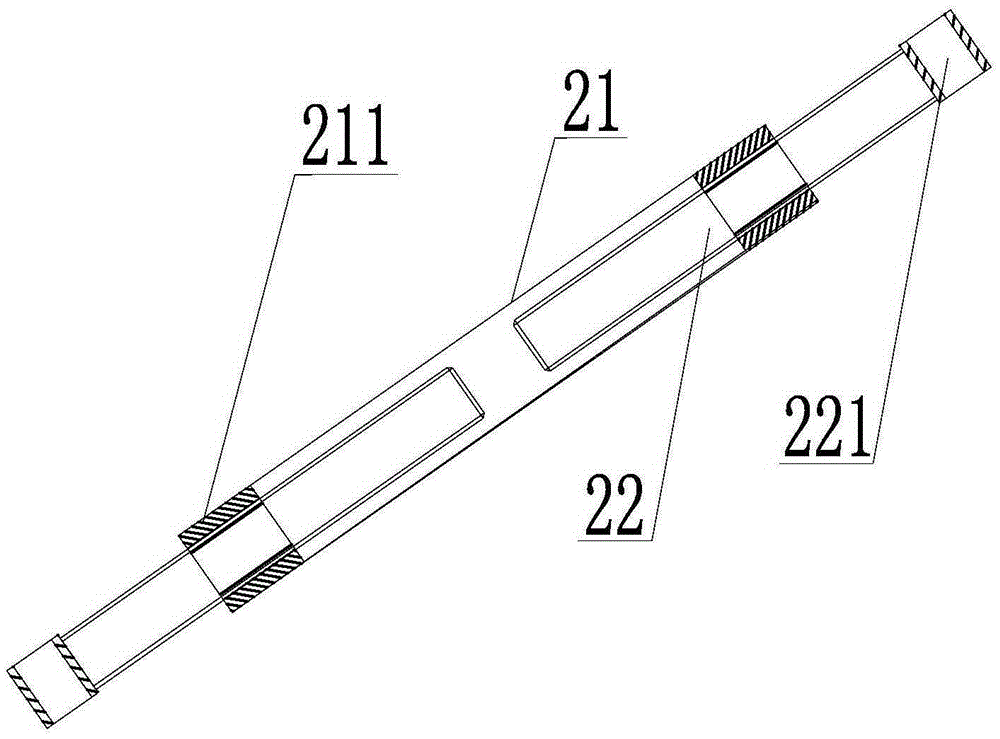

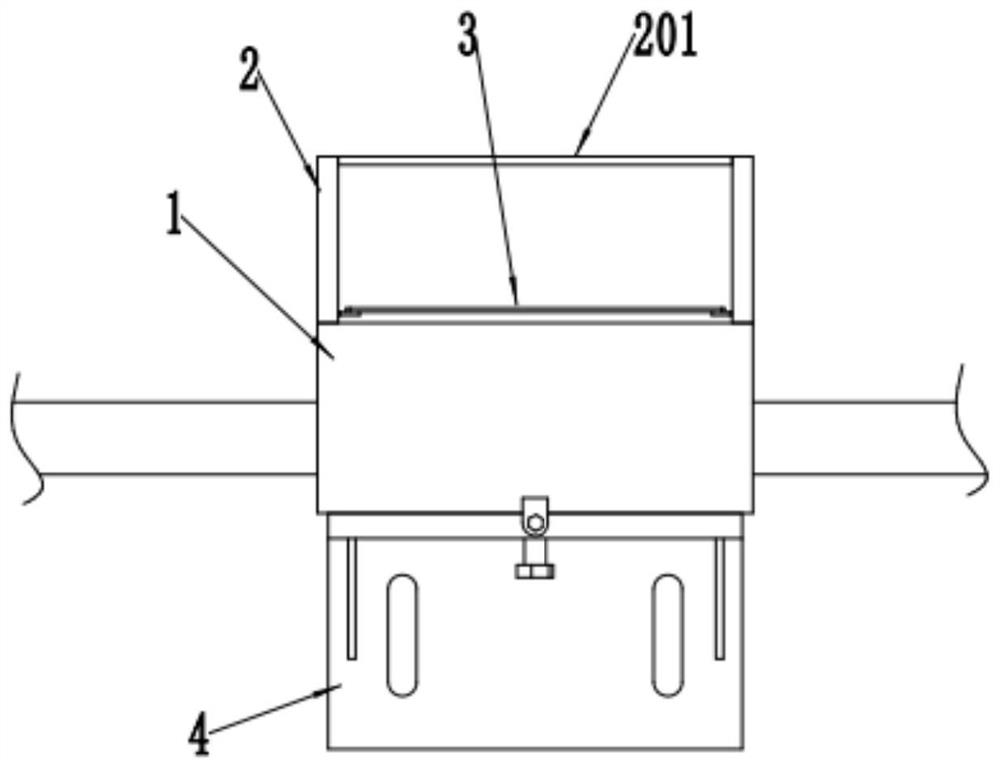

A foundation pit support structure

ActiveCN104294828BSimple processReduce manufacturing costExcavationsArchitectural engineeringMaterial resources

The invention relates to a supporting structure of a foundation pit. The supporting structure comprises a base plate, a supporting base, a supporting rod, a supporting frame, rectangular pipes and a protection plate. The supporting frame comprises a bracket and a second connecting block, the second connecting block is formed by bending a steel plate into a U shape. The whole bracket is formed by bending round steel to be of a U-shaped frame structure, the bracket comprises connecting portions and locating portions, the connecting portions are two pieces of straight round steel welded to the bottom of the second U-shaped connecting block in a spaced mode, the two pieces of straight round steel are parallel to the two side walls of the second U-shaped connecting block respectively, the two locating portions are U-shaped round steel, and the two open ends of the locating portions are fixedly connected with the same ends of the two pieces of straight round steel respectively. The two rectangular pipes are welded to one side of the protection plate in parallel in a spaced mode, the inner sides of the locating portions of the bracket are attached to the two rectangular pipes respectively, a pin penetrates through the bottom of the second connecting block and the protection plate, and a pin sheet is inserted into the end, close to the protection plate, of the pin to fix the bracket and the protection plate. The supporting structure is simple, mounting is convenient, and a large amount of manpower and a large number of material resources are saved.

Owner:杭州爱默乐实验设备有限公司

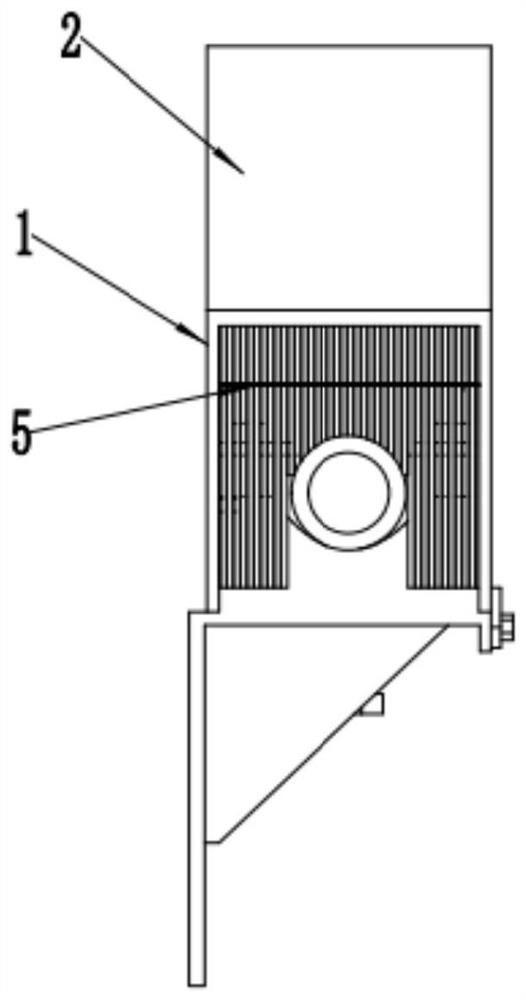

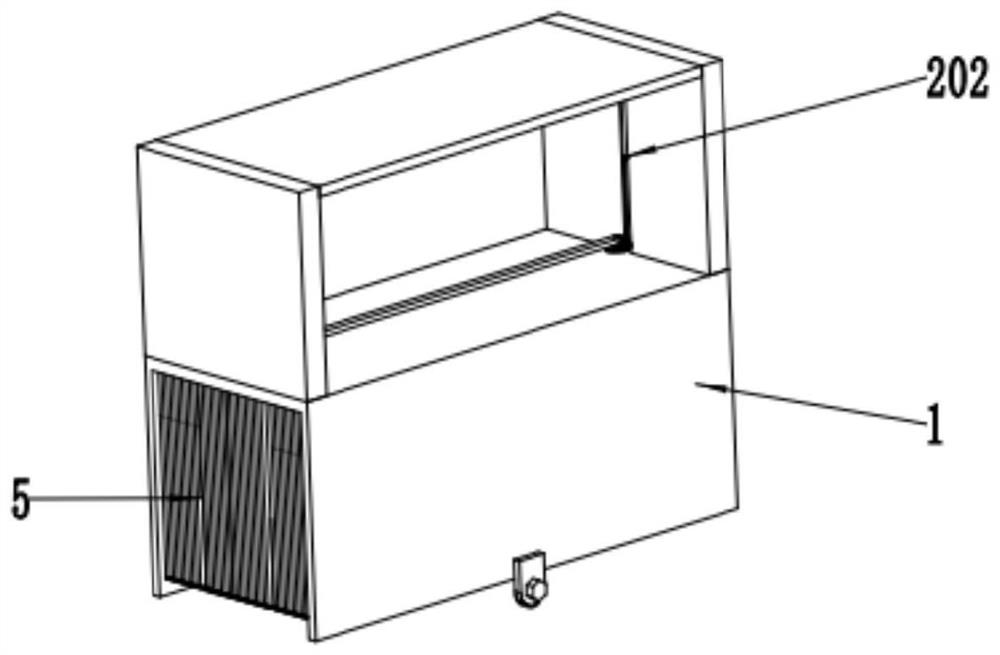

Material screening device

PendingCN109351608AExtended service lifeSolve the problem that feeding cannot be carried out at the same timeSievingScreeningScreening proceduresPush pull

Owner:BEIFANG UNIV OF NATITIES

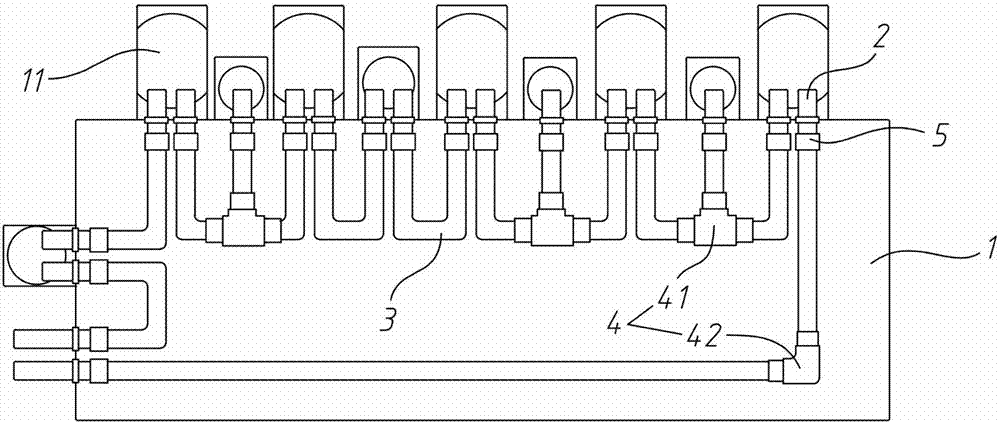

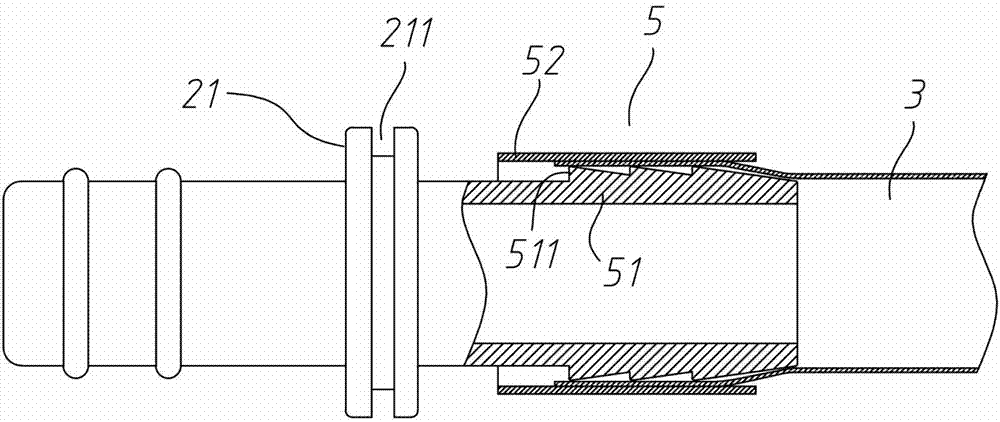

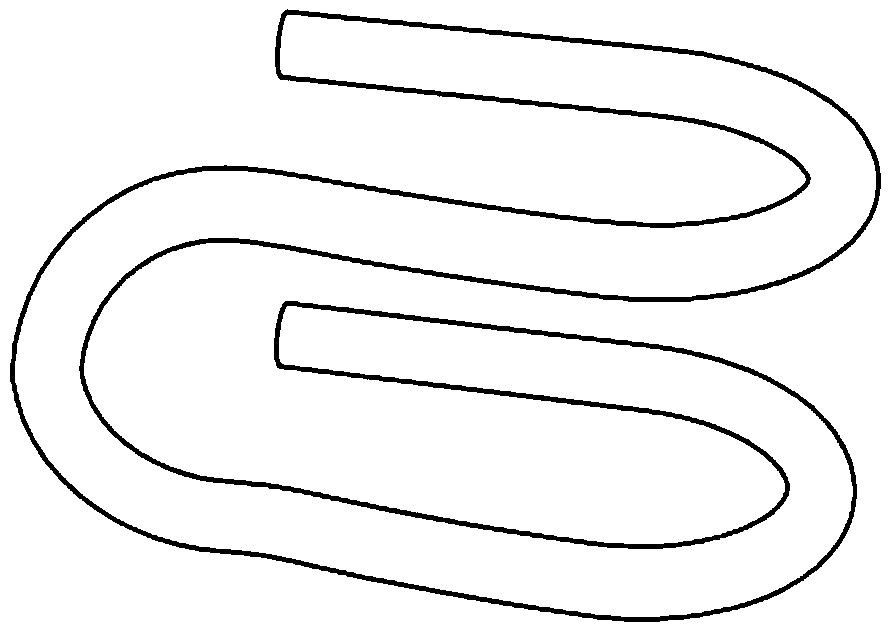

Integrated water path structure of water purifier

PendingCN106966448ANeat and orderly structureEasy to installWater treatment flow arrangementsWater/sewage treatment apparatusPipingSoft water

The invention provides an integrated water path structure of a water purifier. The integrated water path structure comprises a shell which is of a box shape in an encircling manner, a plurality of connection heads, and hoses and pipe fittings which are connected with the respective connection heads, wherein the pipe fittings and the hoses are arranged inside the shell; the connection heads are fixed on the shell, and one end of each connection head extends out of the shell; the hoses, the pipe fittings and the connection heads are connected through joint structures; the joint structures comprise hose joints located on the pipe fittings and the connection heads and fastening caps; the front ends of the hose joints are provided with cone steps; the hoses are connected with the cone steps in a tightened sleeving manner; the fastening caps are connected to the peripheries of the hoses in a tightened sleeving manner. The joint structures cannot scratch pipe walls, do not have fatigue damage and are durable and reliable; by the adoption of the closed shell and the cooperation of standard pieces such as the connection heads, the pipe fittings and the hoses, the integrated water path structure is tidy, easy and convenient to mount and firm; no complicated mold is needed; upgrading of different products or functions with the integrated water path structure can be realized only by increasing or decreasing the quantity of the hoses and the quantity of the connection heads, so that the cost is greatly reduced; the hoses cannot be damaged by freezing expansion, so that the integrated water path structure is applicable to environments at various atmospheric temperatures.

Owner:DONGGUAN CITY ZHUO YI PLASTIC PROD CO LTD

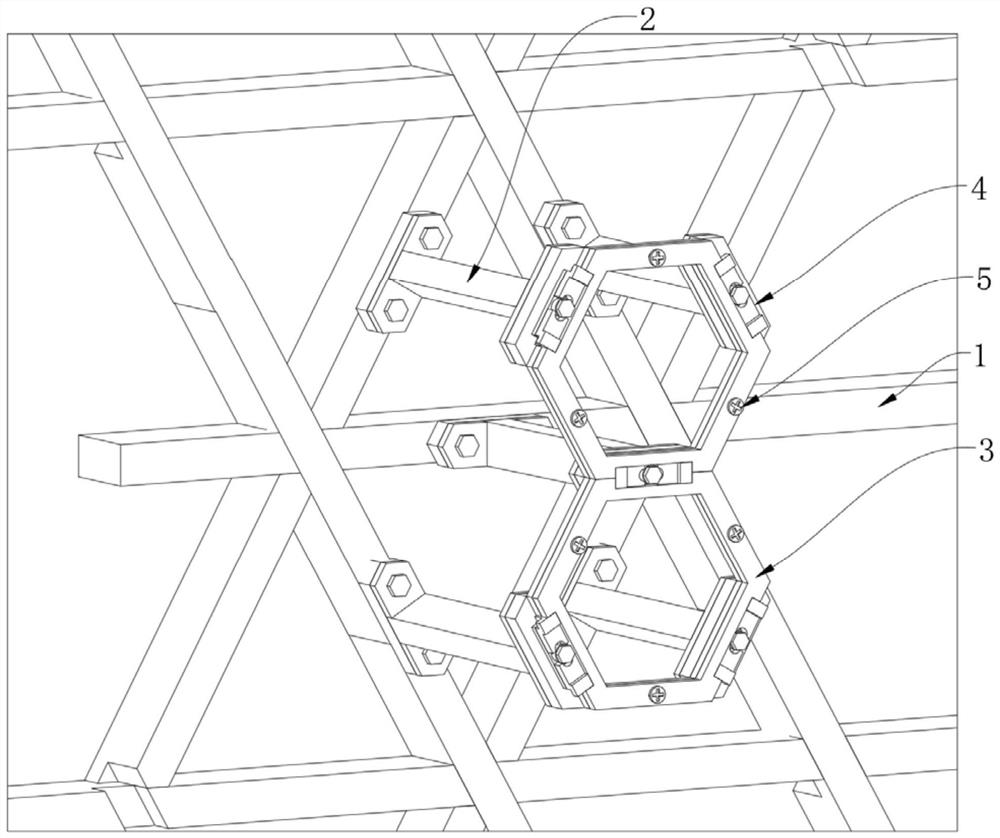

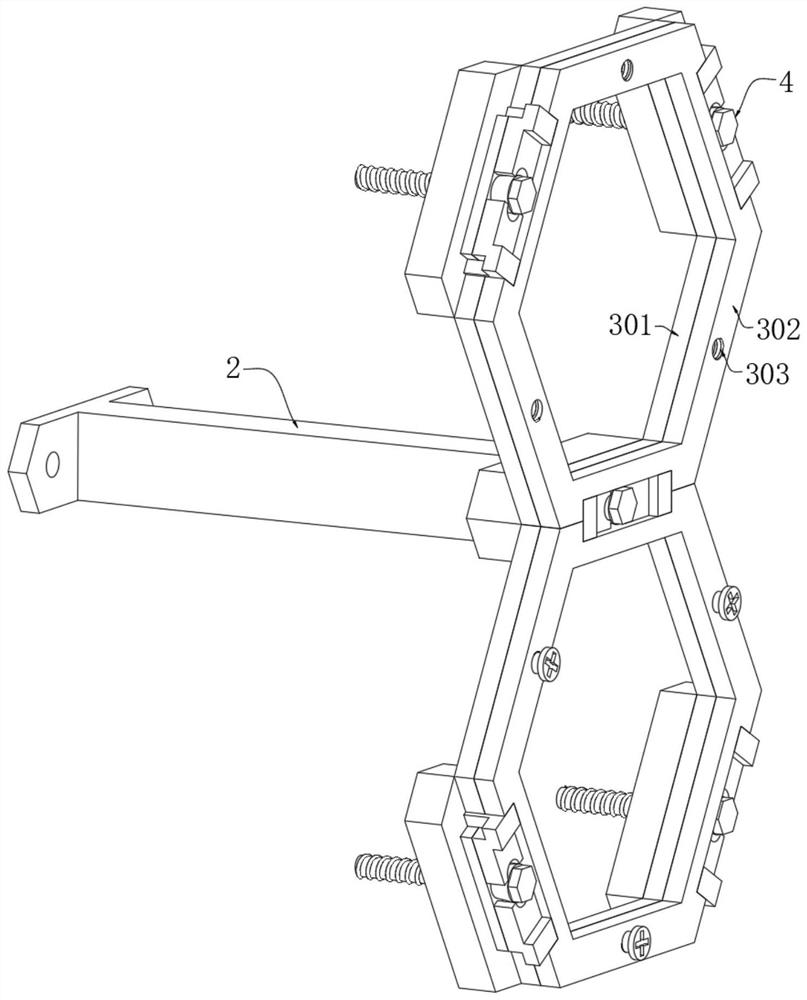

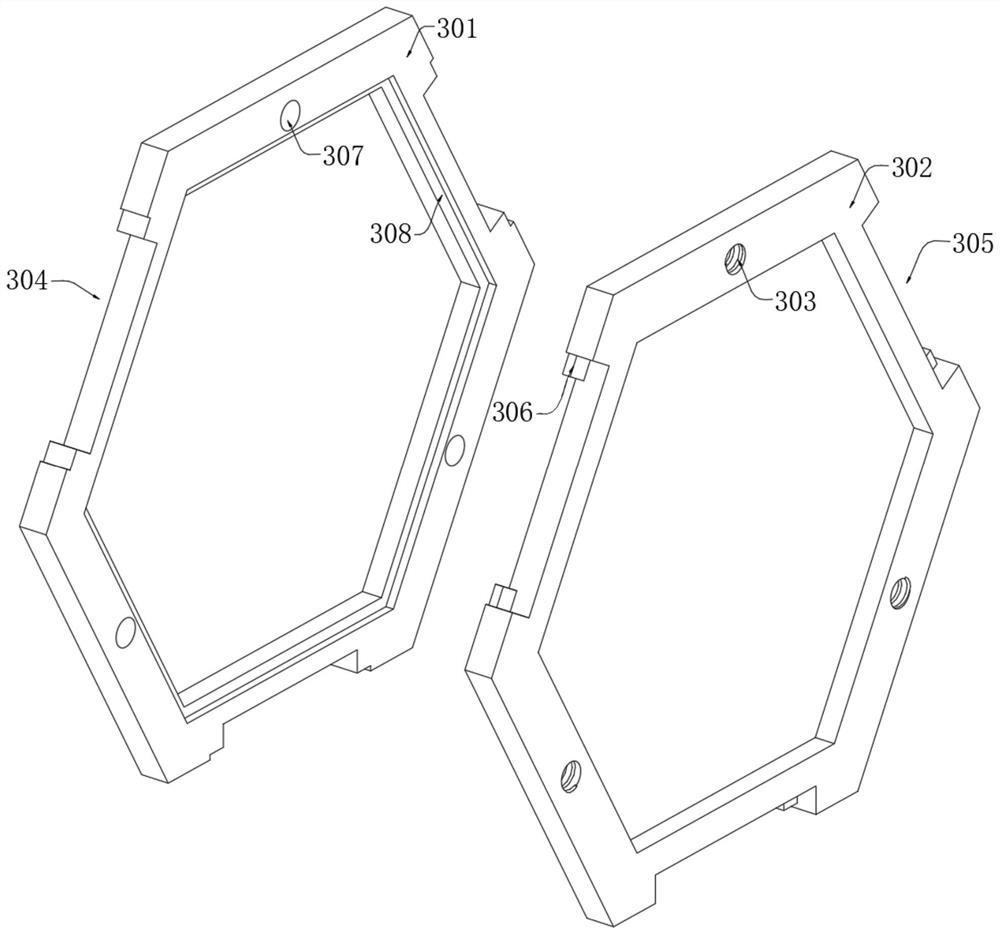

High-strength assembly type curved surface curtain wall structure

PendingCN114016643AEasy to installThe installation process is simple and convenientWallsMechanical engineeringCurtain wall

The invention belongs to the technical field of curtain walls, and particularly relates to a high-strength assembly type curved surface curtain wall structure which comprises a mounting frame, a mounting frame body and a connecting frame used for fixing the mounting frame and the mounting frame body, and the mounting frame body is a regular hexagonal frame, an expansion clamping device and a pan head expansion screw are alternately arranged on the side, away from the connecting frame, of the mounting frame body, the expansion clamping device comprises a fixing plate, a first clamping piece and an expansion bolt, a through second connecting hole is formed in the middle of the fixing plate, and sliding grooves are formed in the positions, located on the two sides of the second connecting hole, of the interior of the fixing plate. According to the invention, the high-strength assembly type curved surface curtain wall structure is provided, a flexible and changeable mounting frame can be provided, the structure adapts to different mounting planes through splicing of a plurality of same mounting frames, the variability of a decorative surface is improved by changing a decorative plate on the surface of the curtain wall, and after the curtain wall is mounted, a single curtain wall unit is convenient to replace.

Owner:深圳市湛艺建设集团有限公司

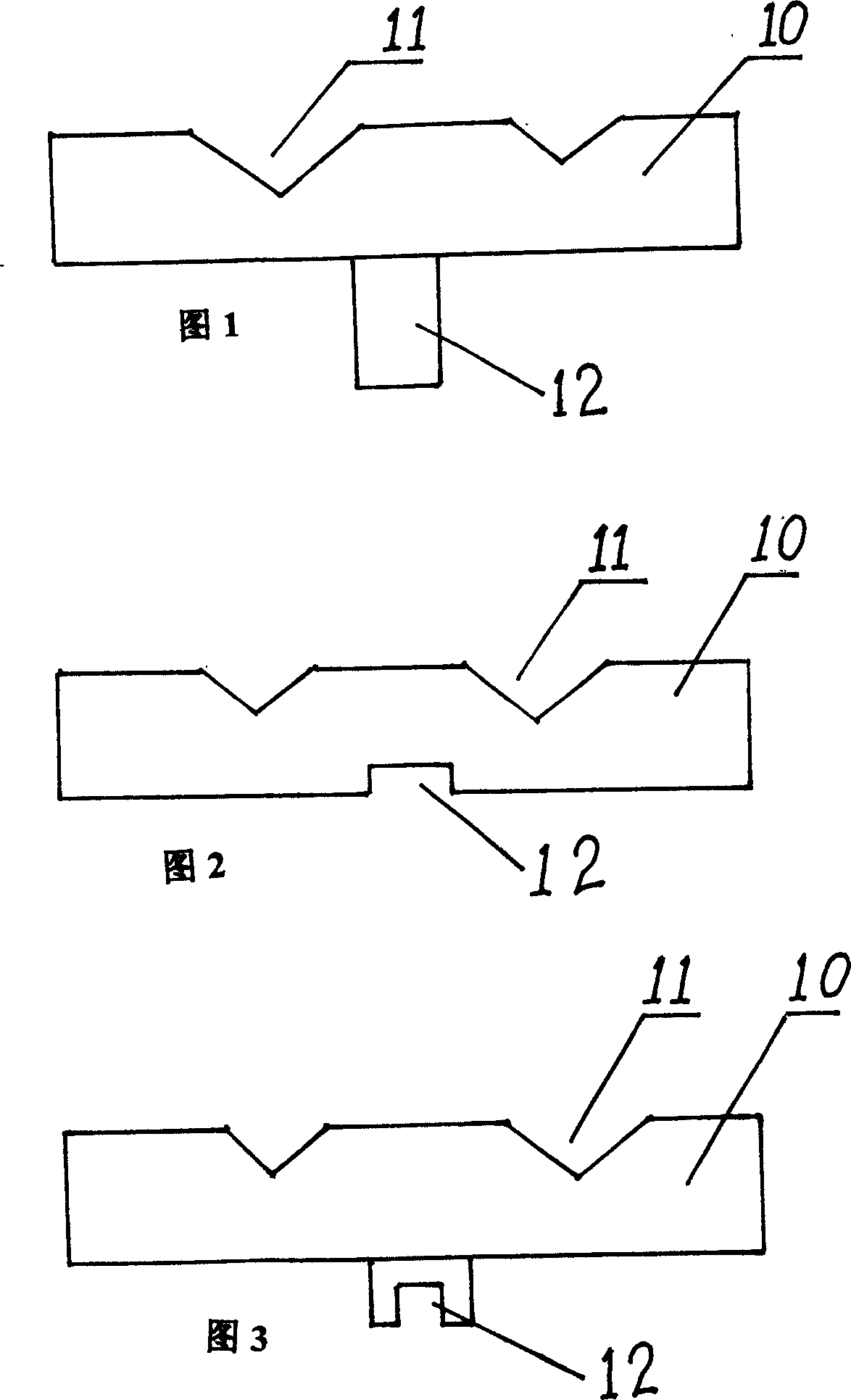

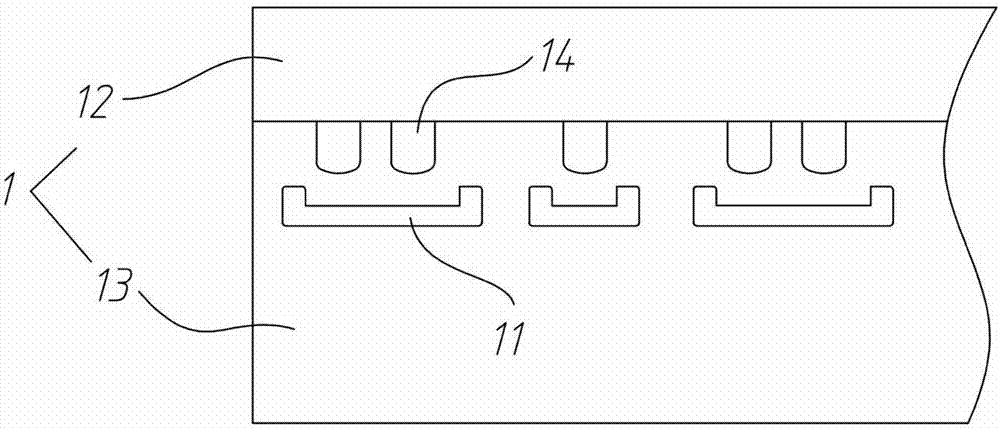

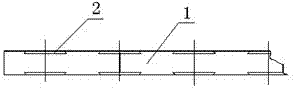

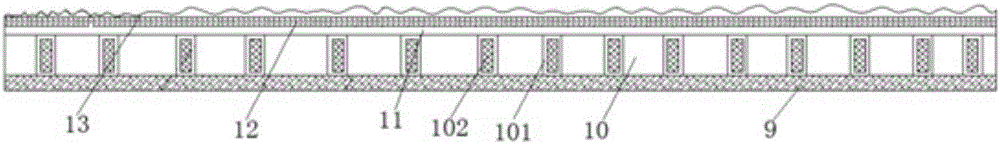

Double-surface heat-insulation plate with wide-bottom pits for buildings

InactiveCN104727448AImprove lateral bearing capacityImprove bearing capacityHeat proofingPull forceSection plane

The invention relates to a double-surface heat-insulation plate with wide-bottom pits for buildings, and belongs to the technical field of energy-saving heat-insulation plate structures for buildings. The double-surface heat-insulation plate comprises a heat-insulation plate body. The heat-insulation plate body is of a double-surface structure, and the pits which are separated from one another are formed in the upper surface and the lower surface of the heat-insulation plate body and are provided with trapezoidal longitudinal sections. The double-surface heat-insulation plate has the advantages that the double-surface heat-insulation plate is reasonable in structural design, convenient to use and wide in application range, perpendicular tensile pulling force of the plate surfaces can be increased, the lateral shearing resistance of the plate surfaces can be improved, the lateral baring capacity of the double-surface heat-insulation plate can be improved after the double-surface heat-insulation plate is embedded in a wall, and all-directional acting force generated by expansion caused by heat and contraction cause by cold can be increased after the double-surface heat-insulation plate is embedded in the wall.

Owner:孙大程

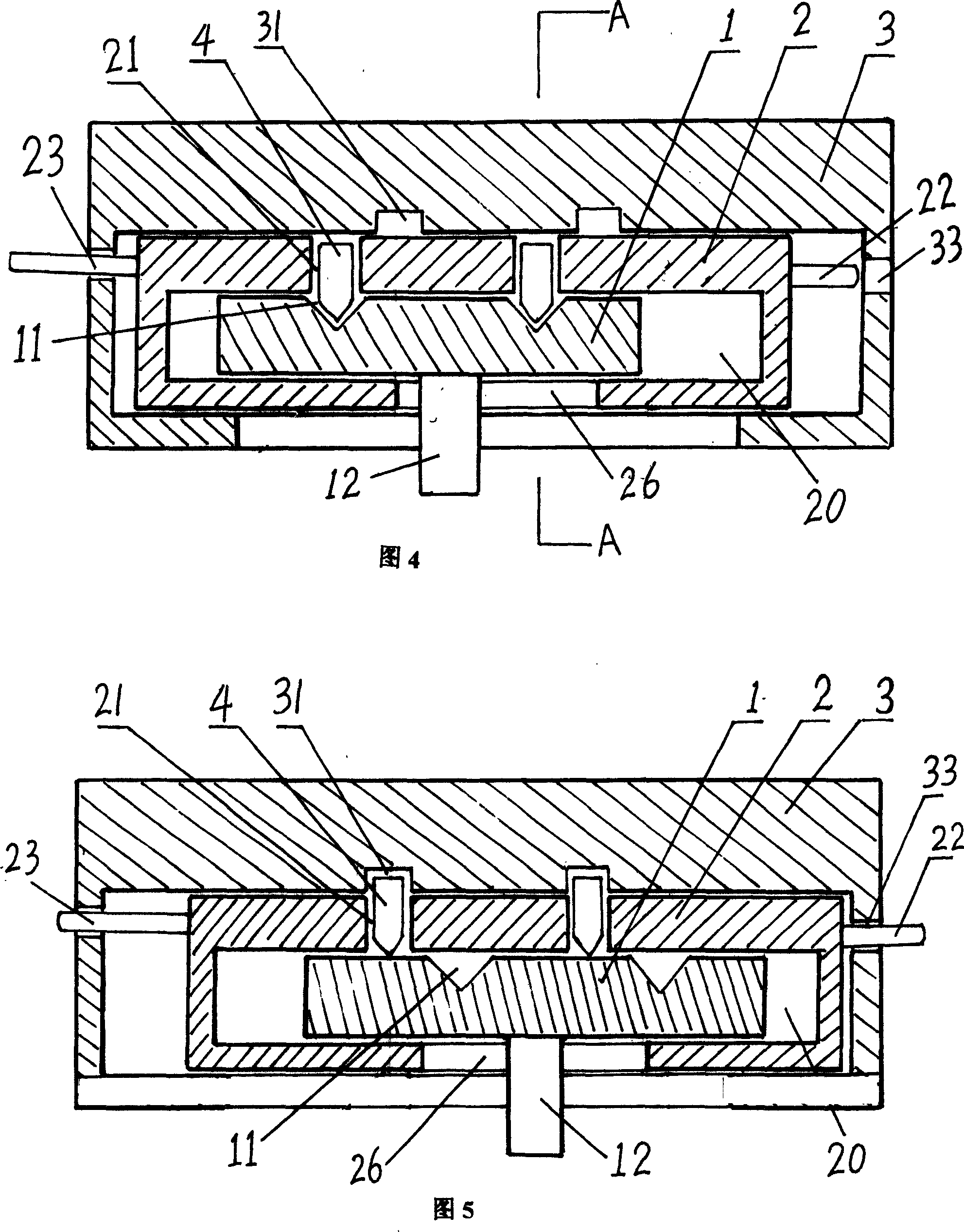

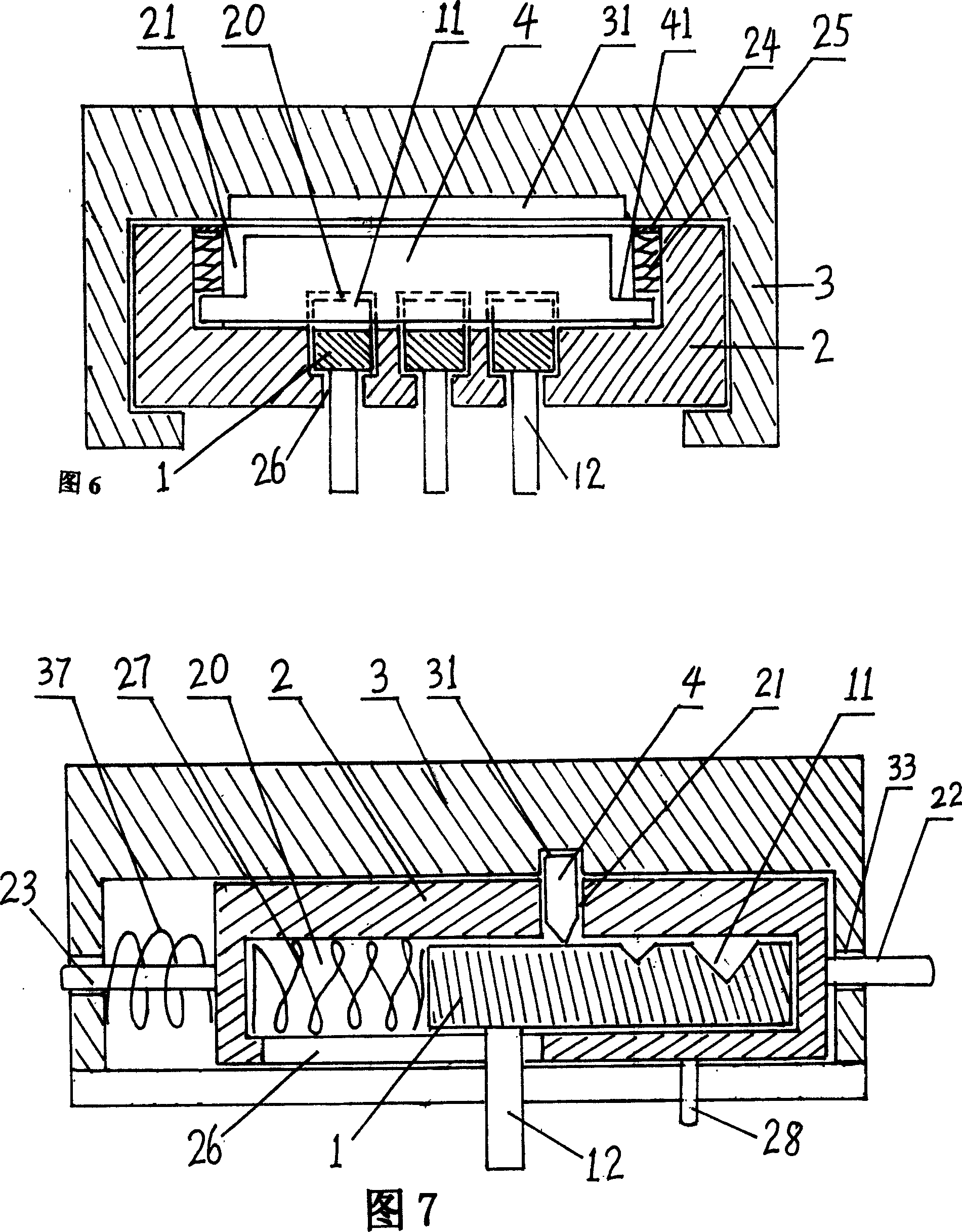

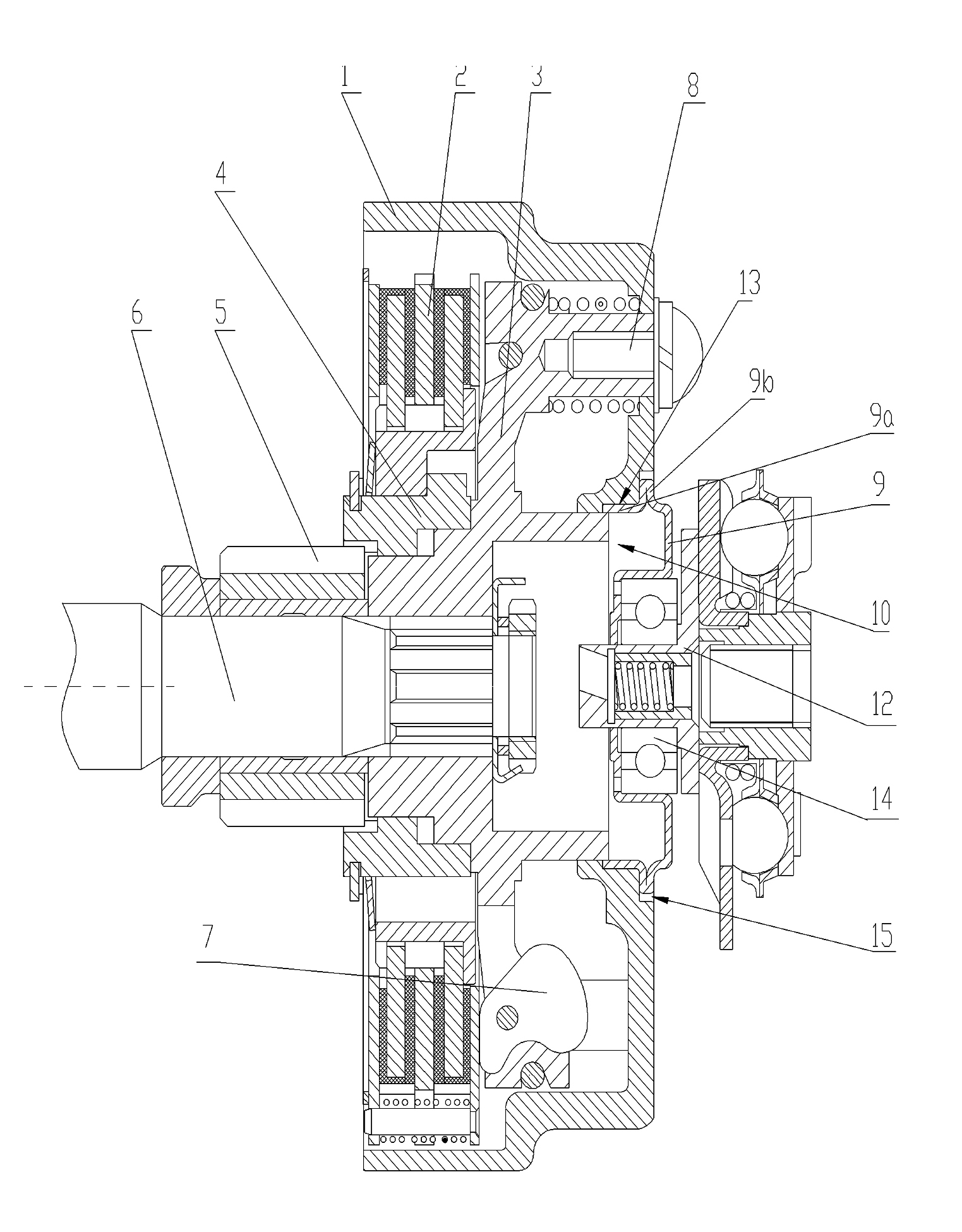

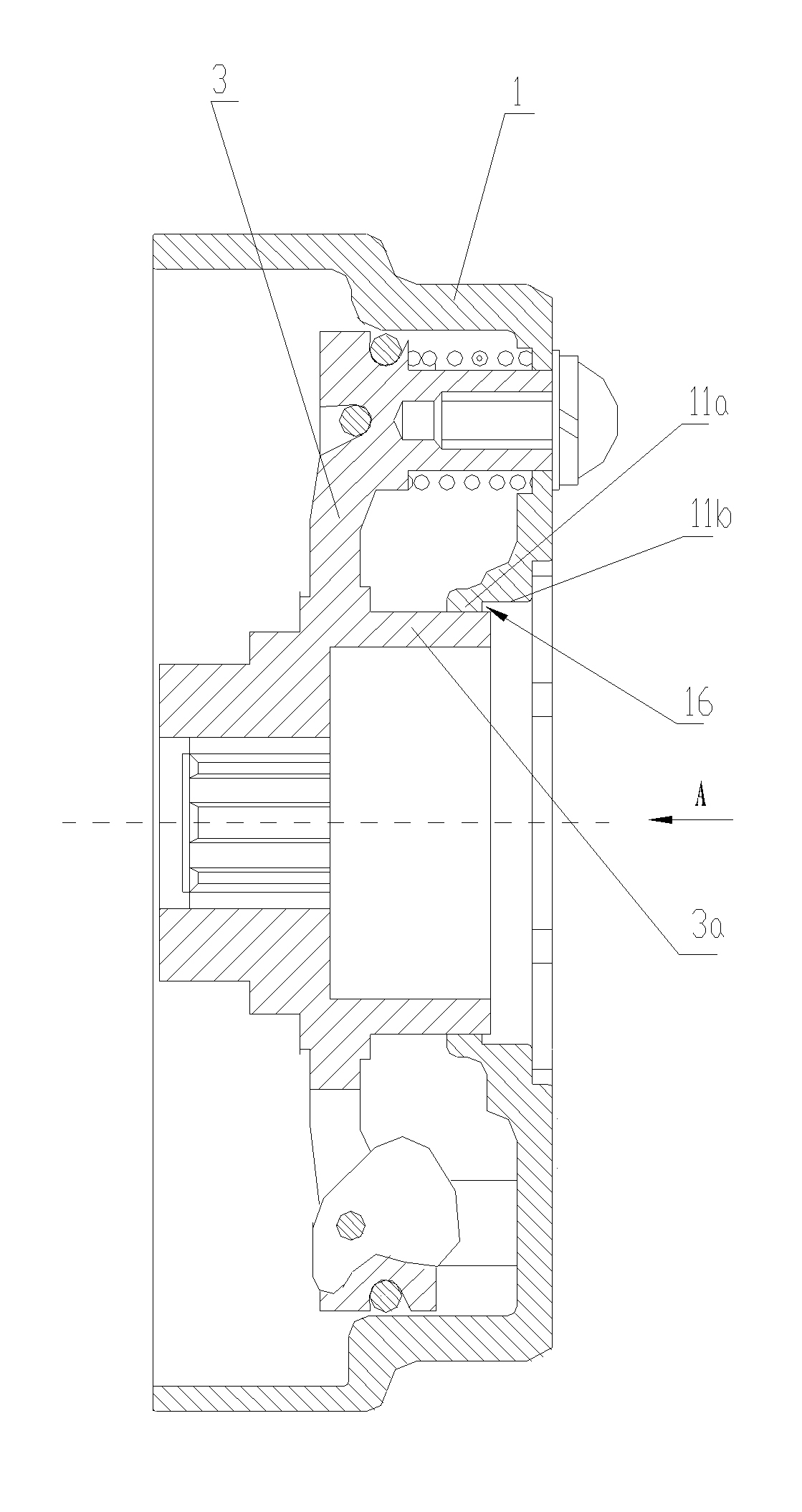

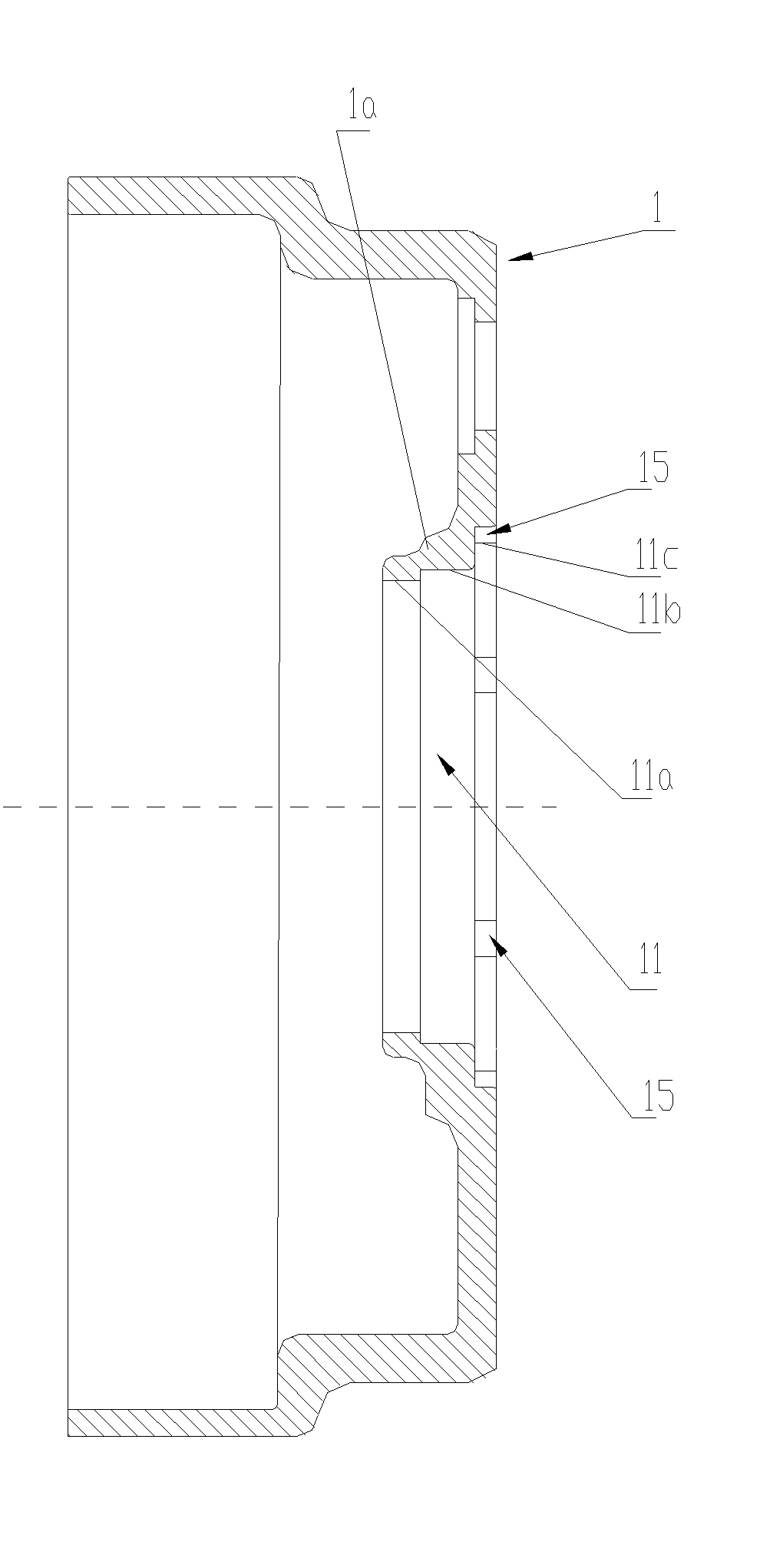

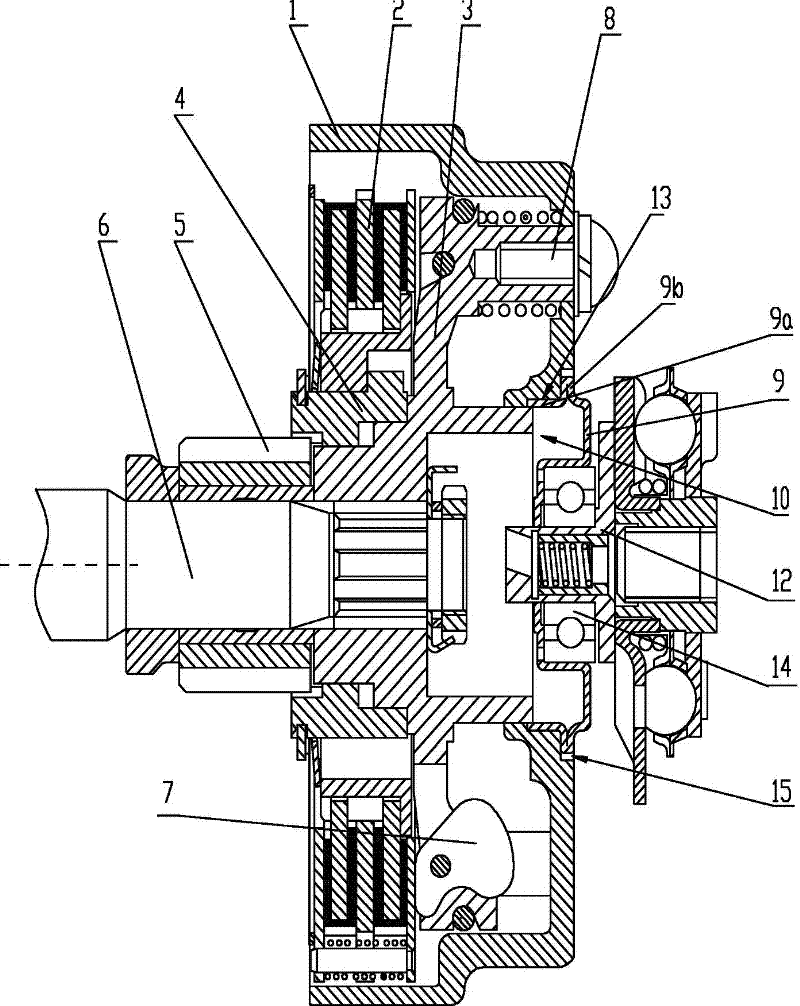

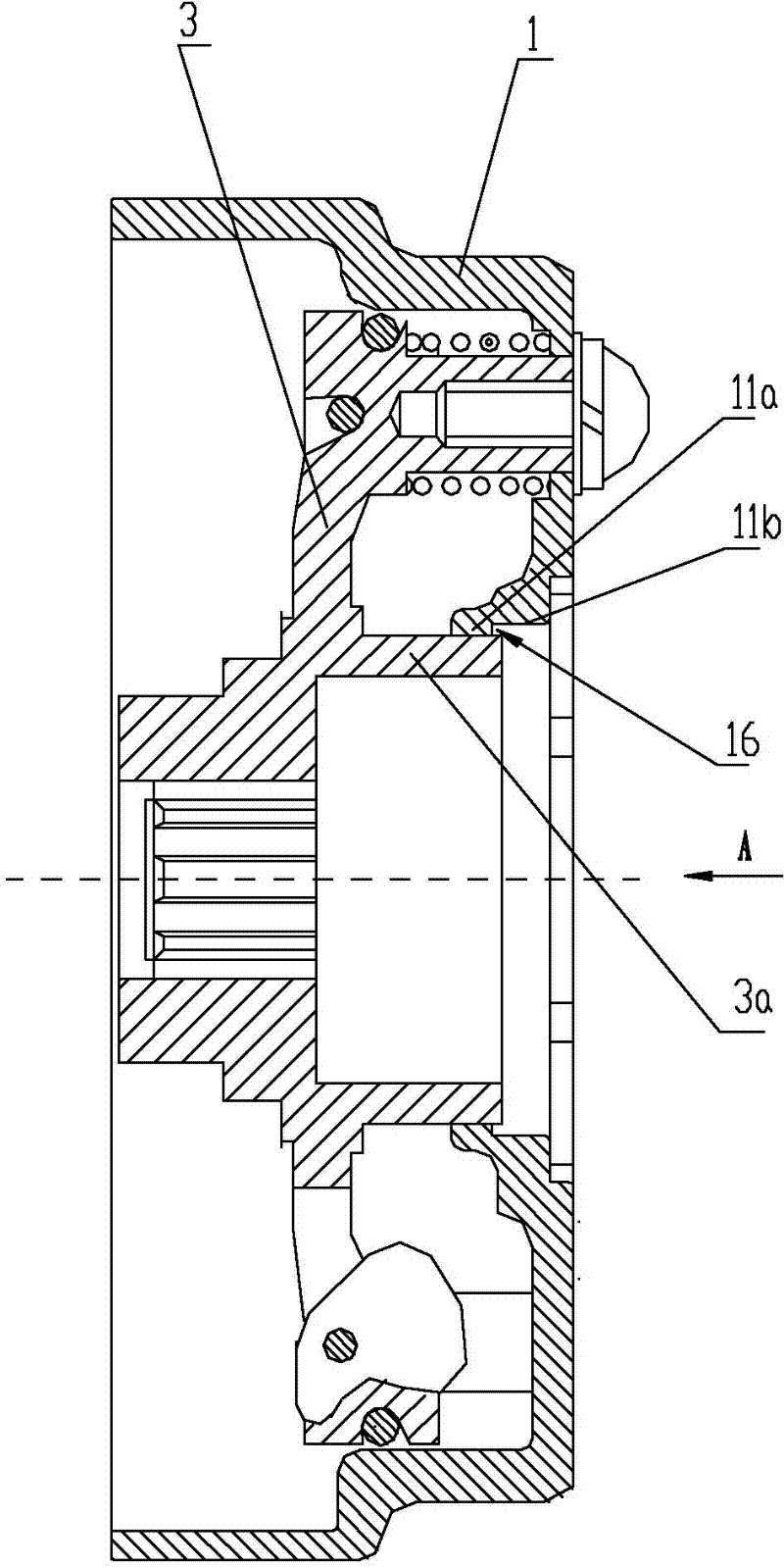

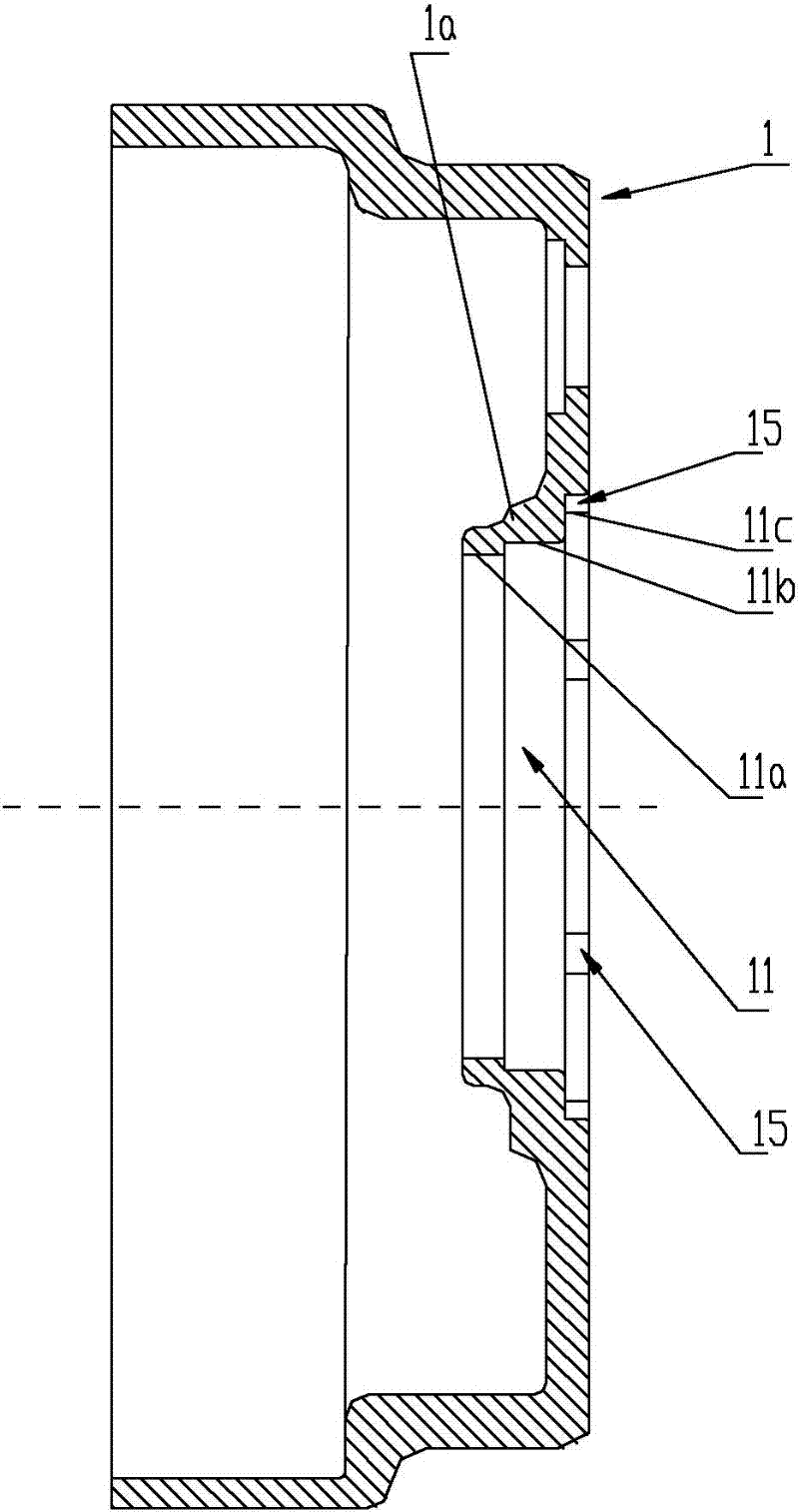

Chip friction clutch

The invention discloses a chip friction clutch. A center through hole of an extension part of the axial end wall in a cavity of a clutch outer cover is a step hole. A first step section of the step hole is a small-diameter section. The hole wall of the small-diameter section is sleeved on a hollow cylinder which extends axially on a driving disc so as to form a ring-shaped groove between the inner wall of a second step section of the step hole and the extension end of the hollow cylinder. The center through hole of the clutch outer cover is covered by an end cover which is formed by carrying out drawing punch forming on a steel plate. The extension end of an axial extension part of the outer peripheral wall of the end cover, which extends toward the cavity of the clutch outer cover, is in interference fit in the ring-shaped groove. A radial extension part which extends radially outwards and turns back and is formed on the axial extension part of the outer peripheral wall of the end cover is clamped and fixed in a third step section of the step hole of the clutch outer cover so as to form labyrinth sealing surfaces with a plurality of turns on the junction surfaces between the end cover and the driving disc and between the end cover and the clutch outer cover, wherein the third step section is a big-diameter section. The clutch can prevent machine oil from being thrown out of the junction surfaces, and the production cost of the clutch can be reduced.

Owner:刘珍利

Process for obtaining transgenosis plant by ovary drop

InactiveCN1624146AShorten the distance into the embryo sacReduce complexityOther foreign material introduction processesPlant Germ CellsTransformation efficiency

A process for preparing the transgenic plant by ovary dripping includes such steps as pollination, germination of pullen particles, male nucleus coming in embryonary sac via pollen tube, cutting off style and 0-1.0 mm of ovary, and dripping exogenous DNA to direct transform reproductive cells or oospores.

Owner:DALIAN UNIV OF TECH

Chip friction clutch

The invention discloses a chip friction clutch. A center through hole of an extension part of the axial end wall in a cavity of a clutch outer cover is a step hole. A first step section of the step hole is a small-diameter section. The hole wall of the small-diameter section is sleeved on a hollow cylinder which extends axially on a driving disc so as to form a ring-shaped groove between the inner wall of a second step section of the step hole and the extension end of the hollow cylinder. The center through hole of the clutch outer cover is covered by an end cover which is formed by carrying out drawing punch forming on a steel plate. The extension end of an axial extension part of the outer peripheral wall of the end cover, which extends toward the cavity of the clutch outer cover, is ininterference fit in the ring-shaped groove. A radial extension part which extends radially outwards and turns back and is formed on the axial extension part of the outer peripheral wall of the end cover is clamped and fixed in a third step section of the step hole of the clutch outer cover so as to form labyrinth sealing surfaces with a plurality of turns on the junction surfaces between the end cover and the driving disc and between the end cover and the clutch outer cover, wherein the third step section is a big-diameter section. The clutch can prevent machine oil from being thrown out of the junction surfaces, and the production cost of the clutch can be reduced.

Owner:刘珍利

Splinter shaped cobbles and its application

InactiveCN1446997AOvercoming the shortcomings of uneven pavingDoes not affect firmnessIn situ pavingsCovering/liningsEngineeringHigh adhesion

A semi-handstone is made up of ordinary handstone through cutting it into two halves, and features that it has a bottom plane and a convex arc surface. It can be used for spreading road or wall decoration. Its advantage is high adhesion to road or wall.

Owner:魏宝学

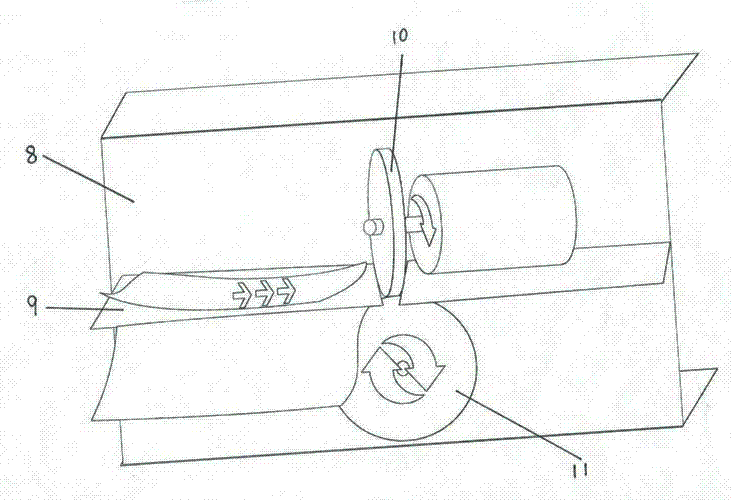

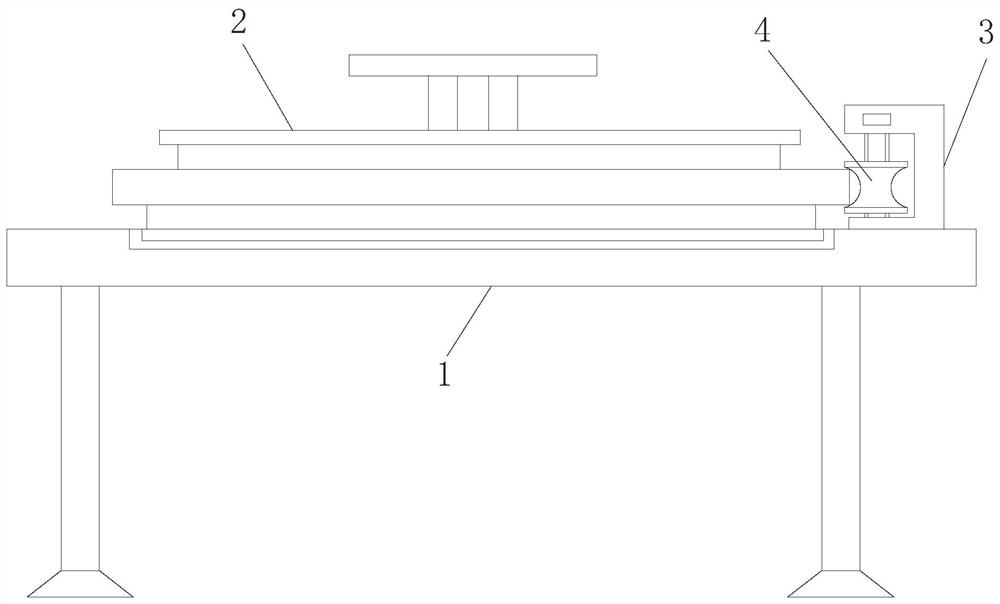

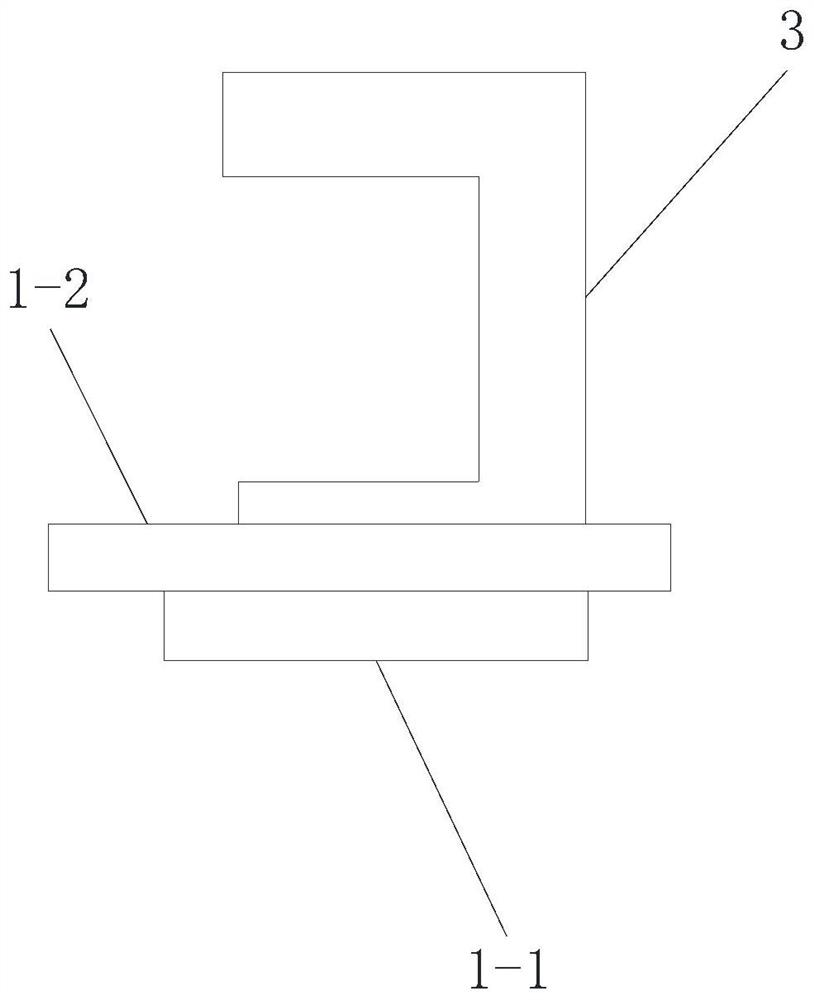

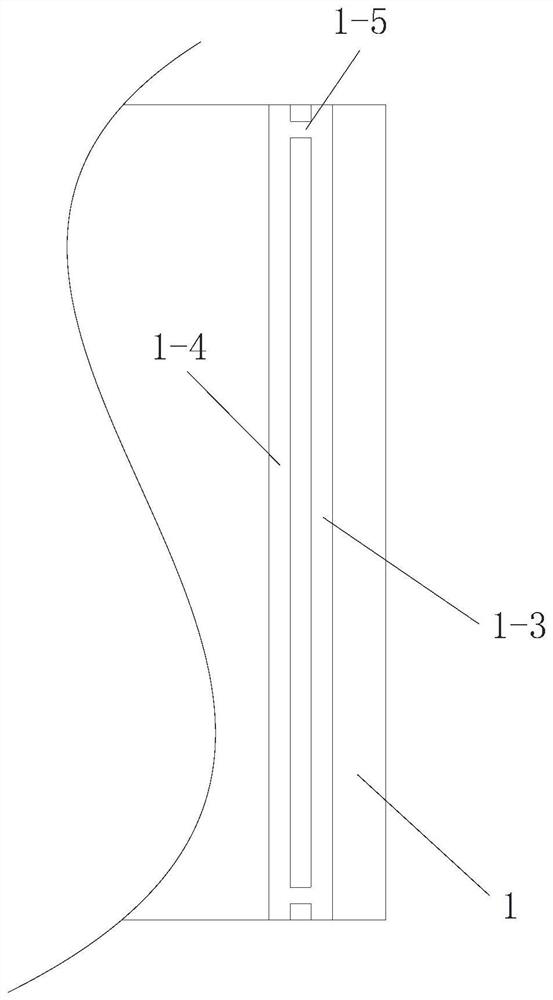

Edge grinding machine

ActiveCN112917301ADoes not affect firmnessImprove grinding effectEdge grinding machinesGrinding work supportsStructural engineeringGrinding wheel

The invention relates to an edge grinding machine. The edge grinding machine comprises a workbench, a fixing device arranged on the workbench and a grinding wheel fixing frame arranged on the workbench, a grinding wheel and a driving device used for driving the grinding wheel to rotate are installed on the grinding wheel fixing frame, and the grinding wheel fixing frame can move front, back, left and right. The grinding wheel is cylindrical and is vertically arranged. The middle part of the grinding wheel is sunken inwards to form an arc-shaped concave surface in the vertical direction. According to the provided edge grinding machine, the fixing firmness of a glass plate is not affected, and the grinding effect is relatively good.

Owner:大冶市古冶玻璃有限公司

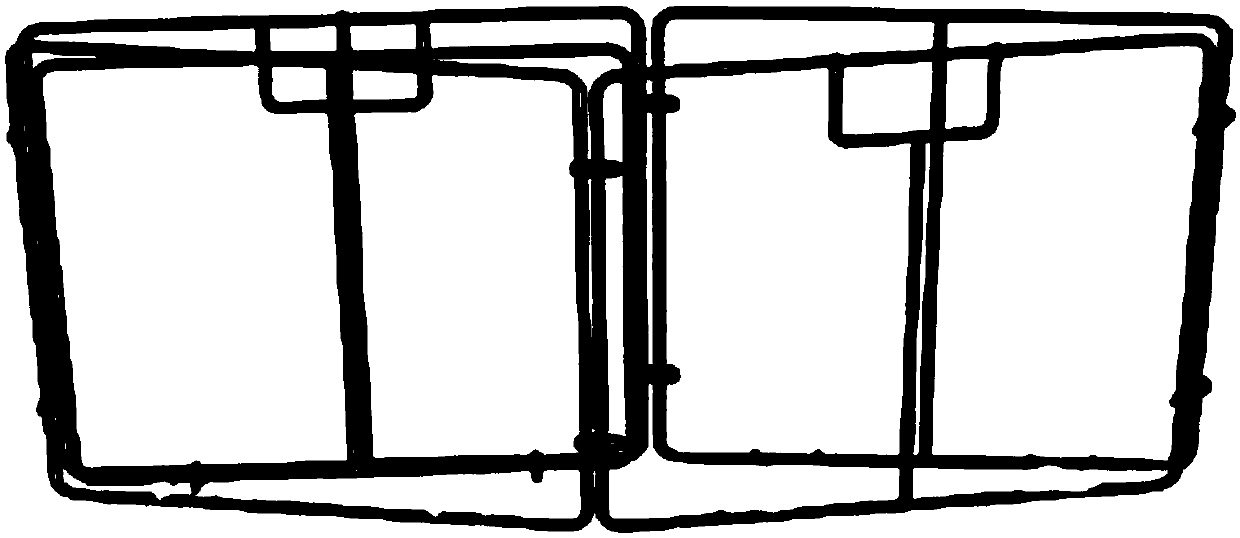

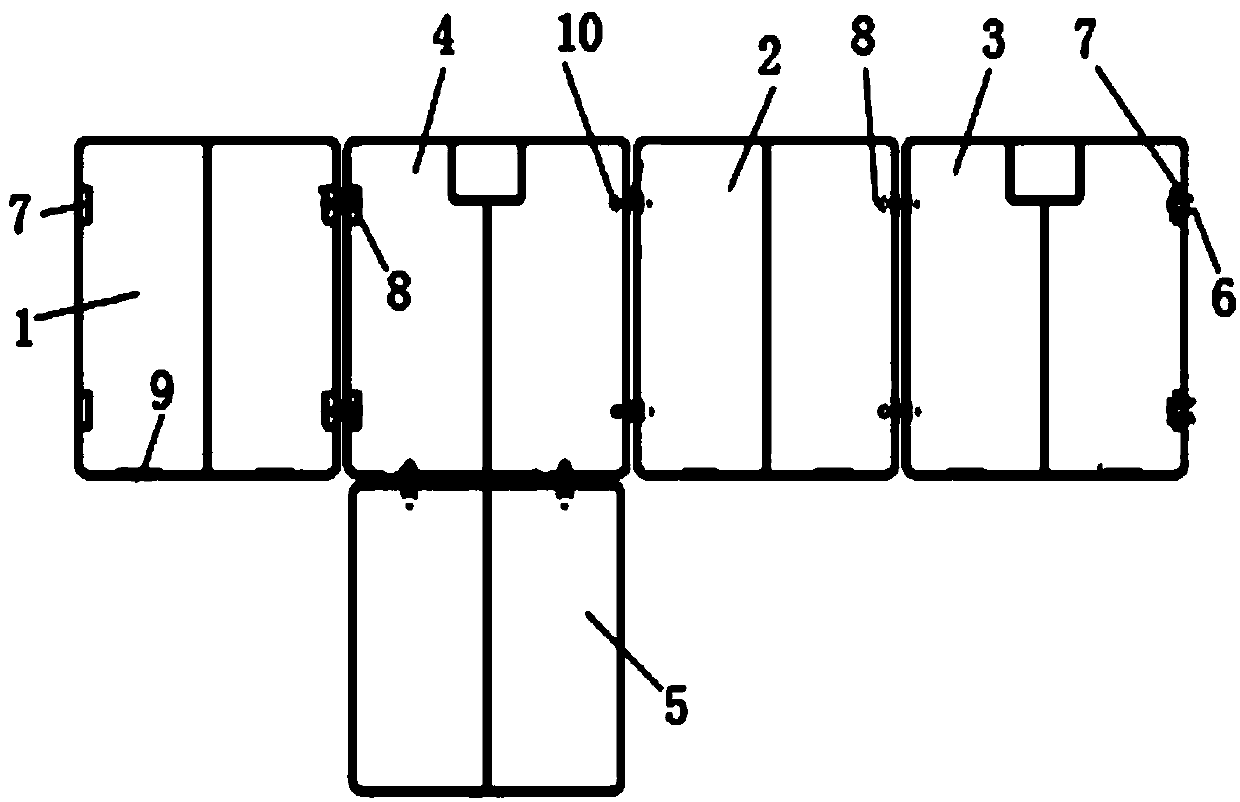

Snap joint type fully folded storage basket

PendingCN107814033ADoes not affect firmnessDoes not affect foldabilityRigid containersJoints typesEngineering

The invention discloses a snap joint type fully folded storage basket. The snap joint type fully folded storage basket comprises four panels: a left panel, a right panel, a front panel and a back panel, and a bottom plate. Adjacent panels can be rotatably connected; opposite sides of at least one pair of adjacent panels are separately and rotatably connected through a snap joint; the bottom plateis rotatably connected to the bottoms of the left panel, the right panel, the front panel or the back panel while supporting portions for supporting the bottom plate are arranged at the bottoms of theother three panels. According to the storage basket disclosed by the invention, the at least one pair of adjacent panels is separately connected in a snap-in connecting mode, so that the fastness, the foldability and the like of the structure are not affected, and the structure can be fully folded to form an area of one panel, and therefore, the occupied space is saved greatly.

Owner:桂林爱索家居用品股份有限公司

Special anti-radiation noise reduction computer heat exchange case for intelligent home

InactiveCN106227308AAvoid interferenceExtended service lifeDigital processing power distributionHuman bodyInsulation layer

The invention discloses a special anti-radiation noise reduction computer heat exchange case for an intelligent home. The special anti-radiation noise reduction computer heat exchange case comprises a case body, an opening-closing door, an air inlet pipeline, an air blower, a dust screen, an air outlet pipeline, a suction fan, a storage cavity, a drawer, a reel, a patch board, a base layer, a sound insulation layer, a division bar, light foam, a reinforced layer, a shielding layer and a noise reduction layer. The special anti-radiation noise reduction computer heat exchange case has the advantages of sound insulation effect and capabilities of improving comfort of workers near the case, decreasing injury to human bodies caused by radiation and solving the problem of automatic power off caused by low cooling rate and easiness in heat emission inside the case of an existing computer host.

Owner:弘毅天承知识产权股份有限公司

Wall external cable joint protection device

ActiveCN113937719AImprove reliabilityAvoid damageClimate change adaptationCable junctionsArchitectural engineeringStructural engineering

The invention discloses a wall external cable joint protection device, which comprises a fixed seat, wherein the upper end of the fixed seat is provided with supporting seats for respectively fixing two connecting cables, a tray for supporting the cable joint is arranged between the two supporting seats, the upper end of the fixed seat is sleeved with a protection cover with two opening ends, and the openings at the two ends of the protection cover are provided with shielding curtains for shielding rainwater. According to the invention, two cables which are connected with each other are supported and fixed through supporting seats, so that the tension between the two cables can be reduced, and disengagement can be avoided; a protection cover and a shielding curtains can play a role in sun protection and water prevention, so that the problems that an insulating adhesive tape at the connecting position falls off and water enters are solved, and the reliability of connection of the two cables is improved; and the protection cover can play a role in isolation and protection, so that the cables are prevented from being touched and damaged by foreign objects, and the use safety is improved.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

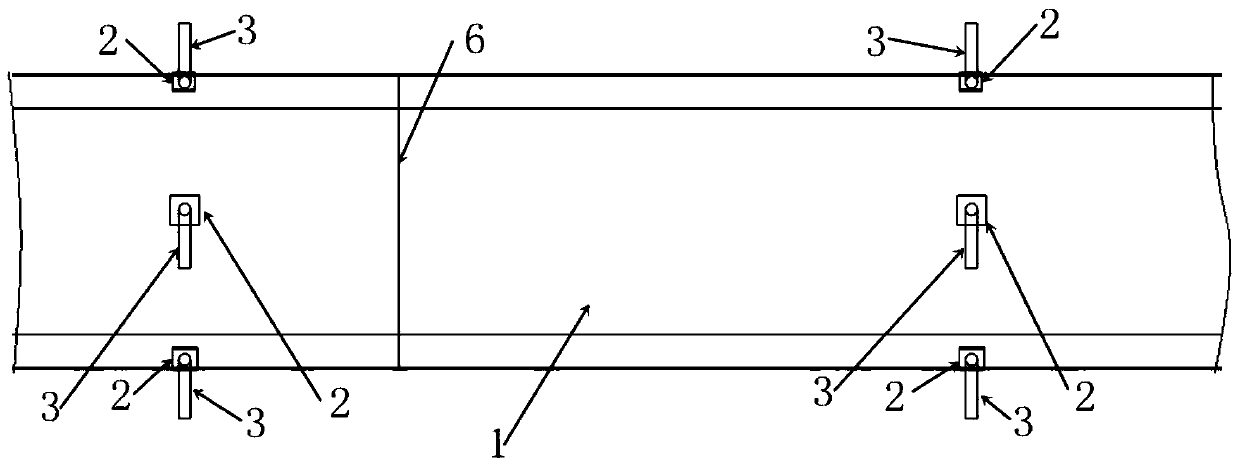

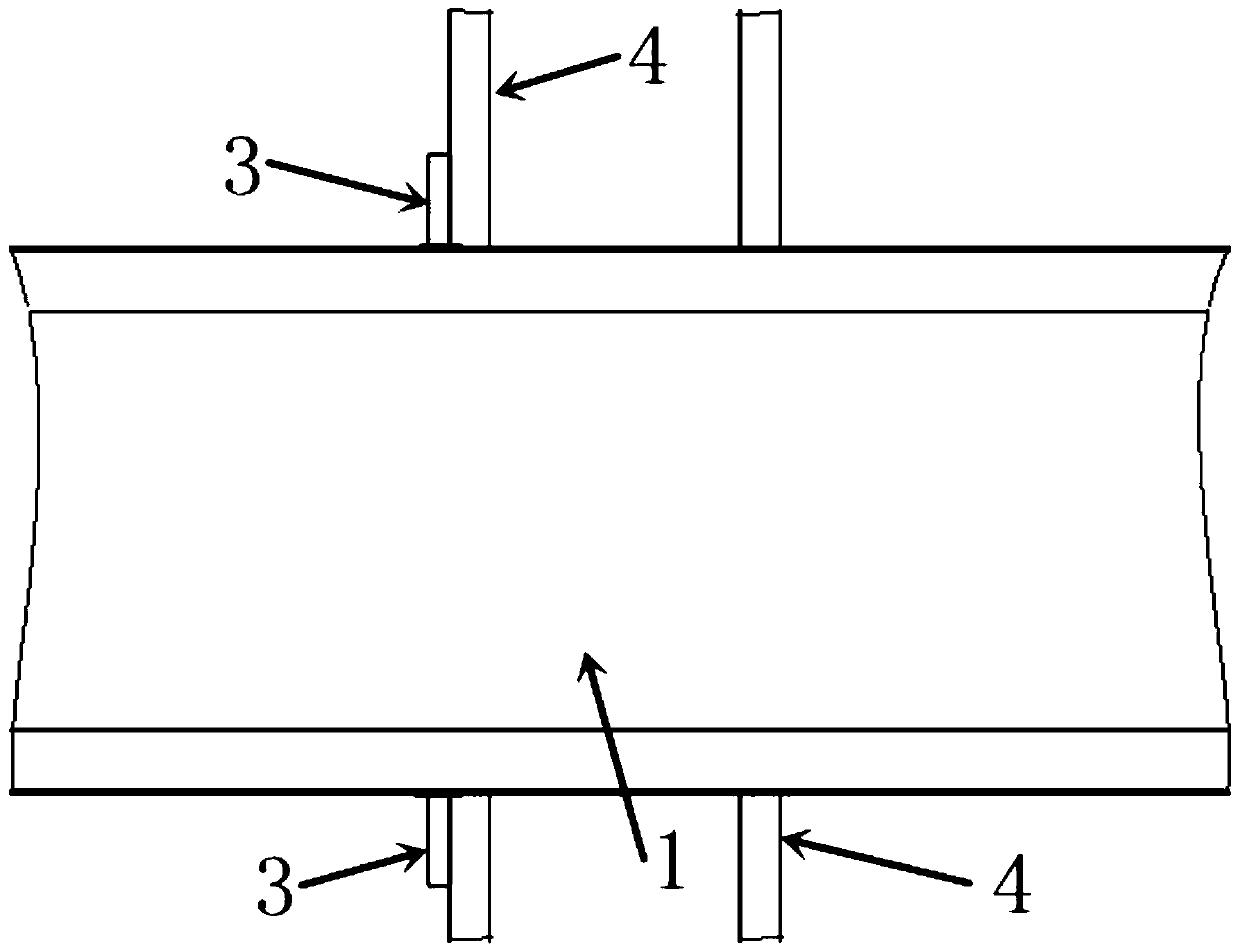

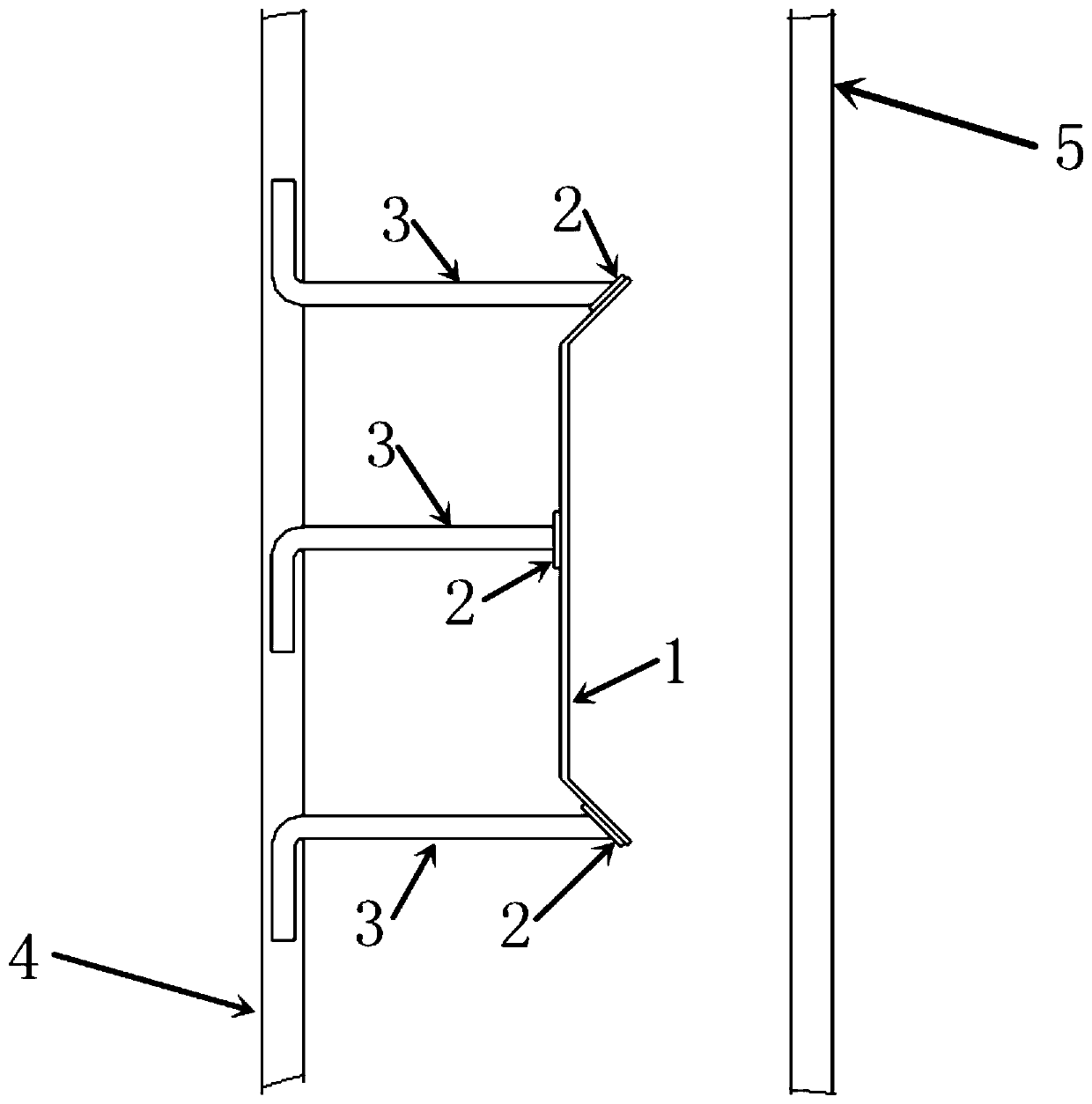

Cast-in-place pipe gallery horizontal construction joint water stopping structure and construction method thereof

The invention relates to a cast-in-place pipe gallery horizontal construction joint water stopping structure. The cast-in-place pipe gallery horizontal construction joint water stopping structure comprises multiple water stopping units which are sequentially arranged in the length direction of a pipe gallery; each water stopping unit comprises a galvanized water stopping steel plate, screw cushionblocks and steel bars; the upper end and the lower end of each galvanized water stopping steel plate are bent, therefore, a notch is formed in each galvanized water stopping steel plate, and each notch serving as an upstream face faces outwards; and each galvanized water stopping steel plate is provided with multiple groups of fixing frames in the length direction, each group of the fixing framescomprise three groups of the screw cushion blocks and the steel bars, the screw cushion blocks are fixed to the downstream faces of the galvanized water stopping steel plates, the first one is fixedto the upper-end bent portion of each galvanized water stopping steel plate, the second one is fixed to the middle of each galvanized water stopping steel plate, the third one is fixed to the lower-end bent portion of each galvanized water stopping steel plate, the steel bars are bent in a right angle shape, the ends of the horizontal sections are fixed to the screw cushion blocks, and the vertical sections are fixed to the inner wall steel bars of the cast-in-place pipe gallery. The invention further relates to a construction method of the cast-in-place pipe gallery horizontal construction joint water stopping structure. The cast-in-place pipe gallery horizontal construction joint water stopping structure is extremely high in fastness, cannot damage base metal, is easy to install and belongs to the technical field of building construction.

Owner:广州市市政工程机械施工有限公司

Method for fixing LED chip on back plate

ActiveCN110911285ASimple processEase of industrial mass productionSolid-state devicesSemiconductor/solid-state device manufacturingElectrical and Electronics engineeringManufacturing engineering

The invention discloses a method for fixing an LED chip on a back plate, which comprises a process of fixing the LED chip on a glass plate, transferring the LED chip to the back plate and fixing the LED chip on the back plate, and the method is simple in process, so that not only is the production efficiency improved, but also the yield in the production process is improved.

Owner:HCP TECH CO LTD

Dying method capable of enhancing dyeing uniformity of elastic safety belt

The invention discloses a dying method capable of enhancing dyeing uniformity of an elastic safety belt. The method comprises the following steps of 1, soaking a weaved safety belt into uncoiling liquid, and drying; 2, soaking the dried safety belt into dye liquor for 3-5min, and then squeezing liquid out, wherein a dye liquor squeezing rate is controlled to be 45-55%; 3, stretching the safety belt to 1.5 times longer than the original length, the steaming, washing by water, and drying to acquired a finished product. The dying method capable of enhancing dyeing uniformity of the elastic safety belt provided by the invention is simple in operation method, uniform in dying and free of generating color difference and colored patches, and the dyed safety belt is not prone to fade, so that quality of the safety belt is greatly enhanced.

Owner:安庆市枞江汽车部件制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com