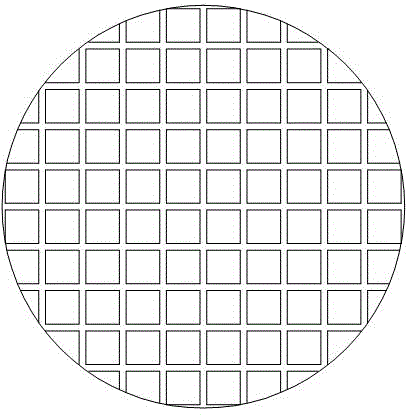

Vertical structure light emitting diode chip with low cost and preparation method thereof

A technology of light-emitting diodes and vertical structures, applied in the direction of electrical components, circuits, semiconductor devices, etc., to achieve the effects of reducing costs, improving production efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

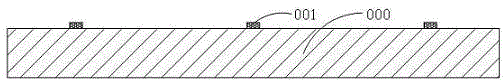

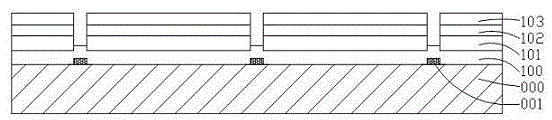

[0061] The invention provides a low-cost vertical light-emitting diode chip, the structure of which includes: a substrate layer, an adhesive layer, a p-side protective layer, a p-side ohmic contact metal layer, an epitaxial layer and an n-electrode; in addition, in order to improve the reliability of the LED chip performance or luminous efficiency, the chip structure preferably also includes one or more of the preparation of a passivation layer, a pattern texture layer for increasing light output, a complementary structure with electrodes, and an optical anti-reflection layer.

[0062] The present invention also provides a preparation method of the above-mentioned low-cost vertical structure light-emitting diode chip. For ease of understanding, first briefly describe the entire process of its chip preparation:

[0063] A. Patterned growth substrate;

[0064] B. Growth of gallium nitride-based LED film, that is, the epitaxial layer;

[0065] C. Depositing the p-side ohmic con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com