Dying method capable of enhancing dyeing uniformity of elastic safety belt

A dyeing method and seat belt technology, which is applied in the field of seat belt dyeing, can solve problems affecting the quality of automobile seat belts, low color fastness, uneven dyeing, etc., and achieve enhanced firmness, dyeing uniformity, and even dyeing , The effect of simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

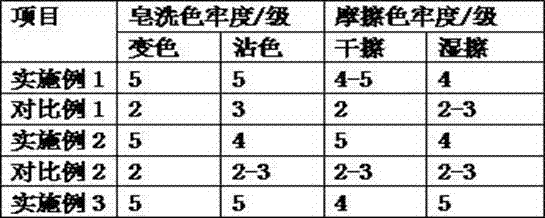

Examples

Embodiment 1

[0018] A dyeing method for improving the dyeing uniformity of an elastic safety belt, comprising the following steps:

[0019] (1) Soak the braided seat belt in a degreasing solution, and then dry it. The degreasing solution is made of the following components in parts by weight: 9 parts of sodium hexafluorophosphate, 5 parts of sodium orthovanadate, propylene sulfonic acid 1 part sodium, 20 parts sodium phosphate, 1 part sodium hydroxide, 190 parts water;

[0020] (2) Soak the dried safety belt in the dye solution for 3 minutes, and then perform padding to control the pad dyeing rate to 45%, wherein the dye solution is made of the following components by weight: 28 parts of acid dye, 5 parts of p-iodophenethyl alcohol, 2 parts of ammonium acetate, 5 parts of potassium methanedisulfonate, 2 parts of penetrant, 1 part of leveling agent, 140 parts of water;

[0021] (3) Stretch the seat belt to 1.5 times the original length, steam it, wash it with water, and dry it to obtain th...

Embodiment 2

[0028] A dyeing method for improving the dyeing uniformity of an elastic safety belt, comprising the following steps:

[0029] (1) Soak the braided seat belt in a degreasing solution and then dry it. The degreasing solution is made of the following components by weight: 12 parts of sodium hexafluorophosphate, 7 parts of sodium orthovanadate, propylene sulfonic acid 1 part sodium, 23 parts sodium phosphate, 1 part sodium hydroxide, 195 parts water;

[0030] (2) Soak the dried safety belt in the dye solution for 4 minutes, and then perform padding to control the pad dyeing rate to 50%, wherein the dye solution is made of the following components by weight: 30 parts of acid dye, 7 parts of p-iodophenethyl alcohol, 3 parts of ammonium acetate, 7 parts of potassium methanedisulfonate, 3 parts of penetrant, 2 parts of leveling agent, 150 parts of water;

[0031] (3) Stretch the seat belt to 1.5 times the original length, steam it, wash it with water, and dry it to obtain the finish...

Embodiment 3

[0038] A dyeing method for improving the dyeing uniformity of an elastic safety belt, comprising the following steps:

[0039] (1) Soak the braided seat belt in a degreasing solution and then dry it. The degreasing solution is made of the following components by weight: 15 parts of sodium hexafluorophosphate, 8 parts of sodium orthovanadate, propylene sulfonic acid 2 parts sodium, 25 parts sodium phosphate, 2 parts sodium hydroxide, 200 parts water;

[0040] (2) Soak the dried safety belt in the dye solution for 5 minutes, and then perform padding to control the pad dyeing rate to 55%, wherein the dye solution is made of the following components by weight: 32 parts of acid dye, 8 parts of p-iodophenethyl alcohol, 4 parts of ammonium acetate, 9 parts of potassium methanedisulfonate, 5 parts of penetrant, 3 parts of leveling agent, 160 parts of water;

[0041] (3) Stretch the seat belt to 1.5 times the original length, steam it, wash it with water, and dry it to obtain the fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com