Cast-in-place pipe gallery horizontal construction joint water stopping structure and construction method thereof

A technology of horizontal construction joints and cast-in-place pipe gallery, applied in underwater structures, infrastructure engineering, water conservancy engineering, etc. The installation of the water-stop steel plate is troublesome and other problems, to achieve the effect of high firmness, high firmness and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with specific embodiments.

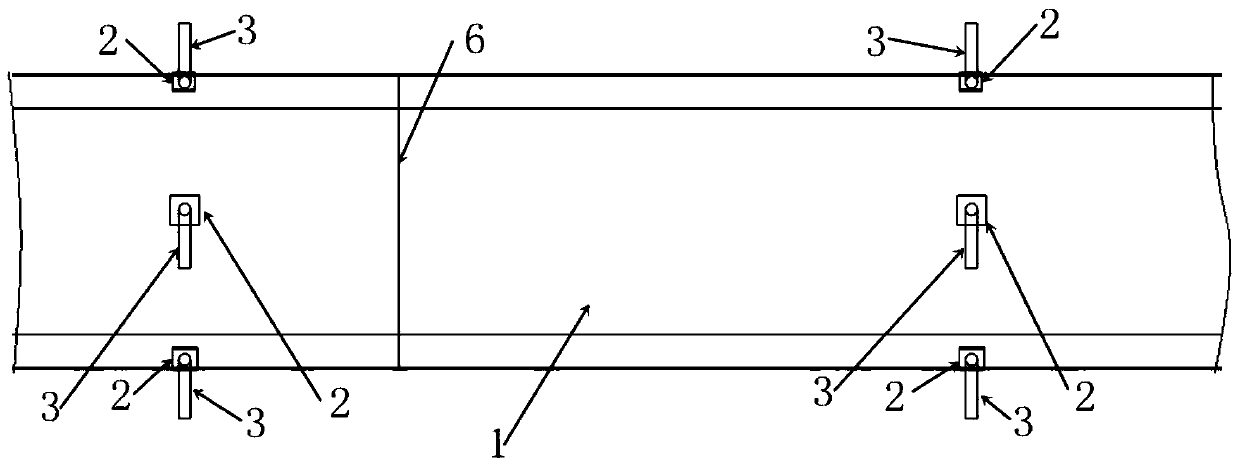

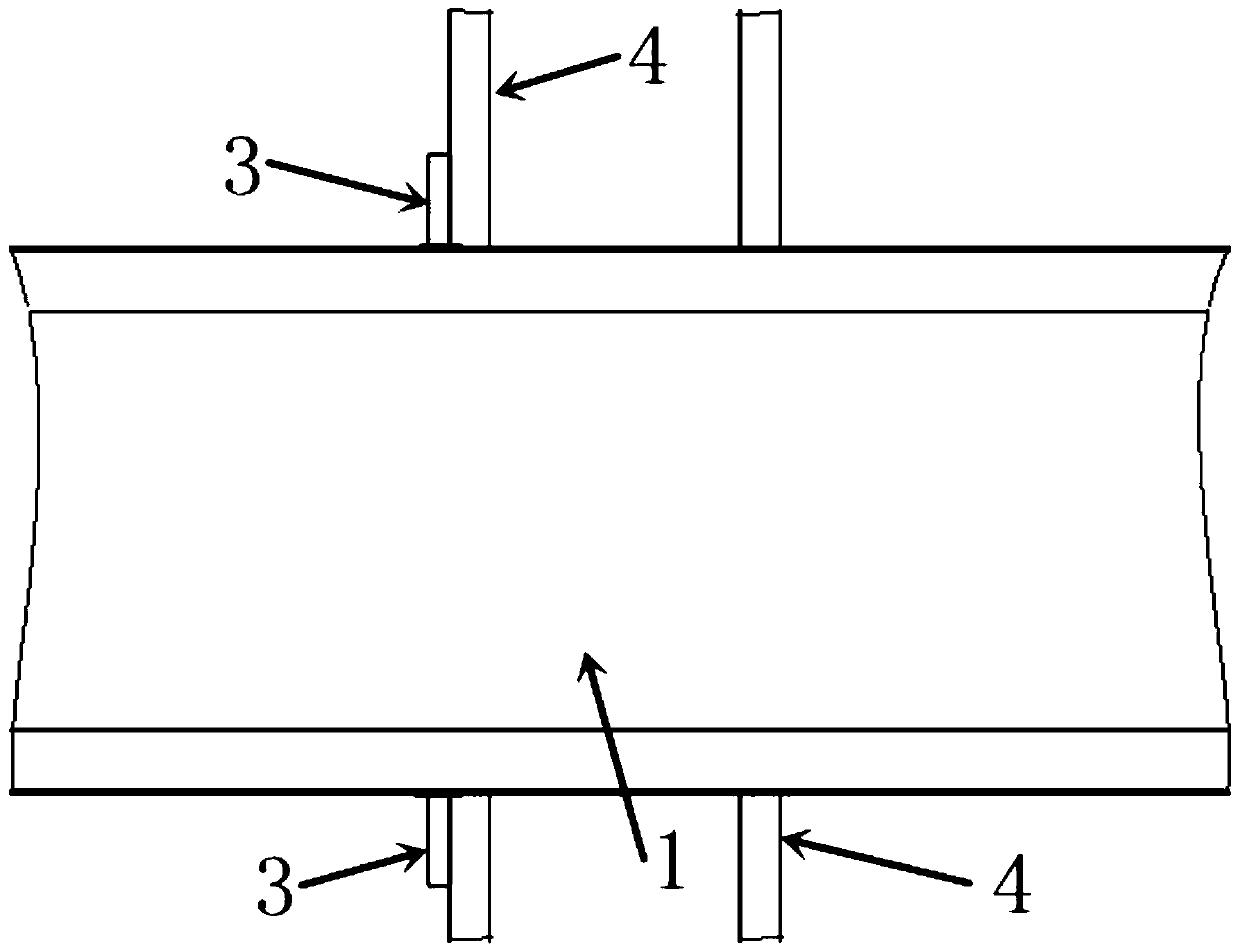

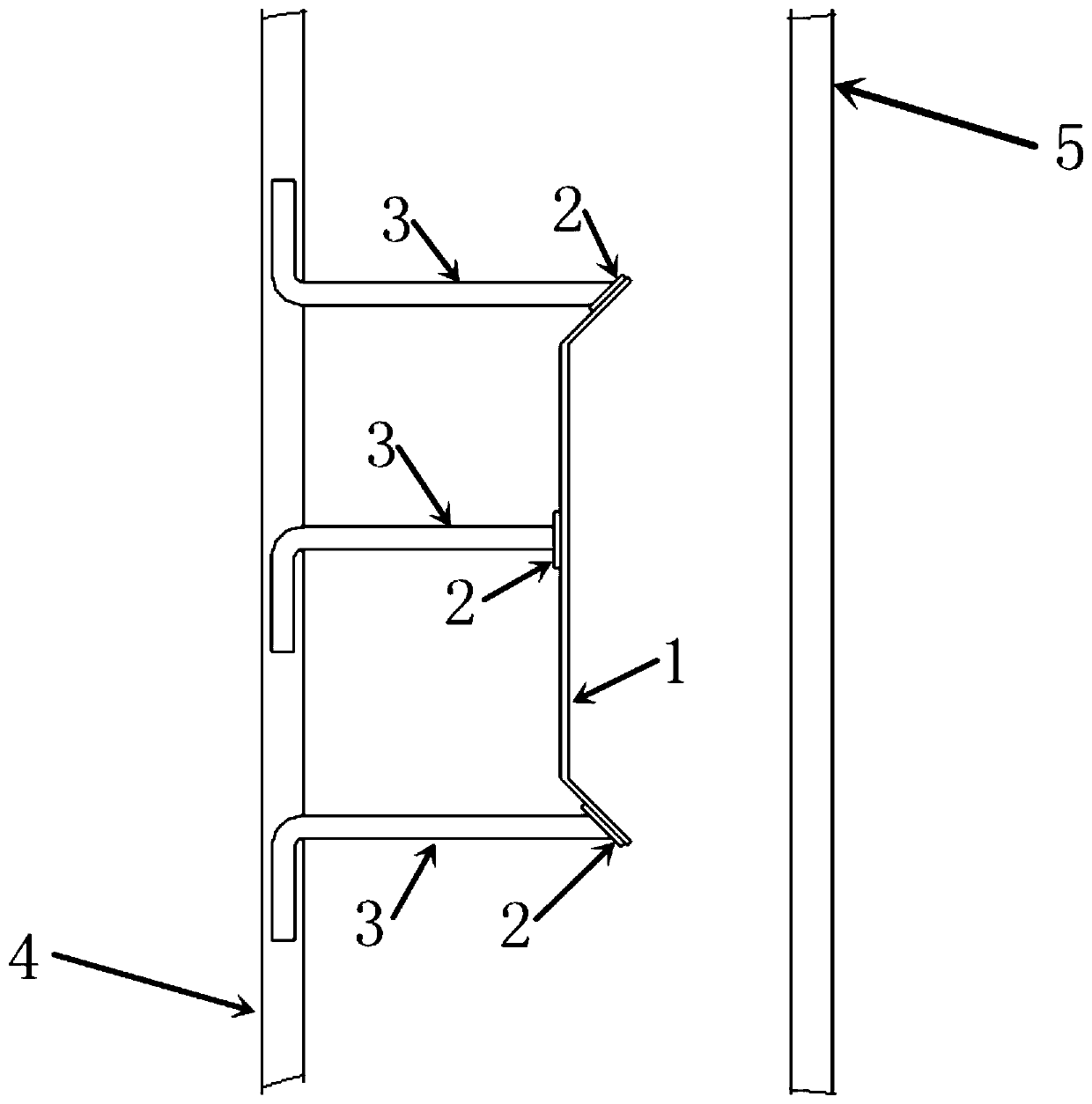

[0033] The water-stopping structure of the horizontal construction joints of the cast-in-place pipe gallery is arranged at the horizontal construction joints of the cast-in-place pipe gallery, and includes a plurality of water-stop units sequentially arranged along the length direction of the pipe gallery. Each water-stop unit includes galvanized water-stop steel plates, screw spacers, and steel bars.

[0034] The midline position of the galvanized water-stop steel plate is set at the cast-in-place horizontal construction joint, the notch of the galvanized water-stop steel plate is set facing the upstream surface, and the welding between the two galvanized water-stop steel plates of adjacent water-stop units should be full and double-sided. For surface welding, the overlap of galvanized water-stop steel plates is not less than 50mm; the screw spacer is to avoid da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com