Double-surface heat-insulation plate with wide-bottom pits for buildings

A technology for thermal insulation boards and buildings, applied in thermal insulation, building components and other directions, can solve the problems of lack of interlocking effect and lack of mechanical interlocking force, and achieve the effect of improving mechanical locking force, tight joint surface and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

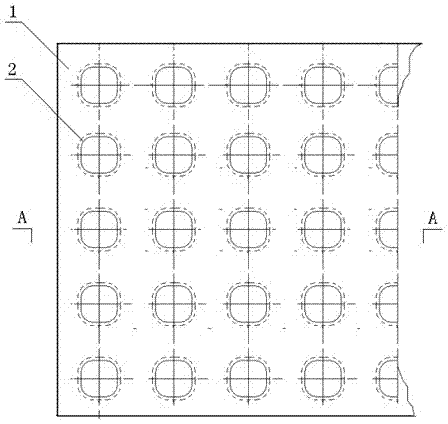

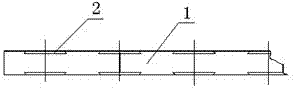

[0037] In this embodiment, an insulation board with wide-bottomed pits on both surfaces for construction, refer to the attachment Figure 1-2 , Including a double-surface structure of the insulation board body 1, on the upper surface and the lower surface of the insulation board body 1, pits 2 with a narrow upper mouth and a wide bottom surface are arranged at even intervals in sequence. The depth of the pits 2 is to match the base material And depending on the combination method, the strong base can be as shallow as 5-7 mm, the weak base can be as deep as 7-15 mm, the pouring method can be as deep as 7-15 mm, and the plastering method can be as shallow as 5-7 mm. The shape of the pit opening of the pit 2 is designed to be a square with rounded corners. The adjacent pits 2 are horizontal or perpendicular, and the angle between the inner bottom surface of the pit 2 and the side wall of the pit is 30°-80°. The insulation board body 1 is XPS polystyrene extruded board.

[0038] The ...

Embodiment 2

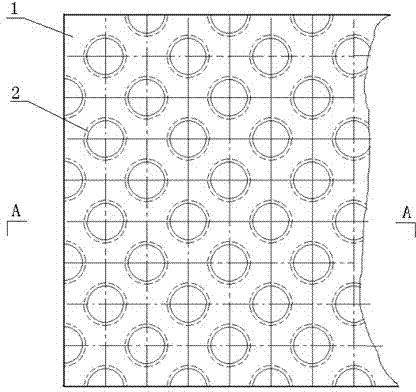

[0040] In this embodiment, an insulation board with wide-bottomed pits on both surfaces for construction, refer to the attachment Figure 3-4 , Including an insulation board body 1 with a double-surface structure. The upper and lower surfaces of the insulation board body 1 are arranged with pits 2 evenly spaced. The width of the pits 2 is smaller than the width of the pit bottom. The pit shape of the pits 2 is designed as Circular, adjacent rows of pits 2 are arranged alternately, the angle between the inner bottom surface of the pits 2 and the side walls of the pits is 30°-80°, and the depth of the pits 2 is in accordance with the mutual engagement of the matrix material and the bonding method Depending on the strength of the matrix, it can be as shallow as 5-7 mm, the weaker matrix can be as deep as 7-15 mm, the pouring method can be as deep as 7-15 mm, and the wall plastering method can be as shallow as 5-7 mm, pit 2 The corner between the side wall and the upper or lower sur...

Embodiment 3

[0043] In this embodiment, an insulation board with wide-bottomed pits on both surfaces for construction, refer to the attachment Figure 5-6 , Including an insulation board body 1 with a double-surface structure. The upper and lower surfaces of the insulation board body 1 are arranged with pits 2 evenly spaced. The width of the pits 2 is smaller than the width of the pit bottom; the pit shape of the pits 2 is designed as The middle is rectangular and the two sides are semicircular. The pits 2 in adjacent rows are arranged alternately; the angle between the inner bottom surface of the pits 2 and the side walls of the pits is 30-80°, 60° is the best, the pits The depth of 2 is determined by the material of the matrix and the combination method. The strong matrix can be as shallow as 5-7mm, the weak matrix can be as deep as 7-15mm, and the pouring method can be as deep as 7-15mm. The method can be as shallow as 5-7 mm. The corner between the side wall of the pit 2 and the upper or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com