A foundation pit support structure

A technology of foundation pit support and support rods, which is applied in the direction of foundation structure engineering, excavation, construction, etc., can solve the problems of flat support occupying the space in the pit, long construction period, and increased project cost, so as to achieve convenient installation and disassembly and low production cost. Low, eliminate the effect of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

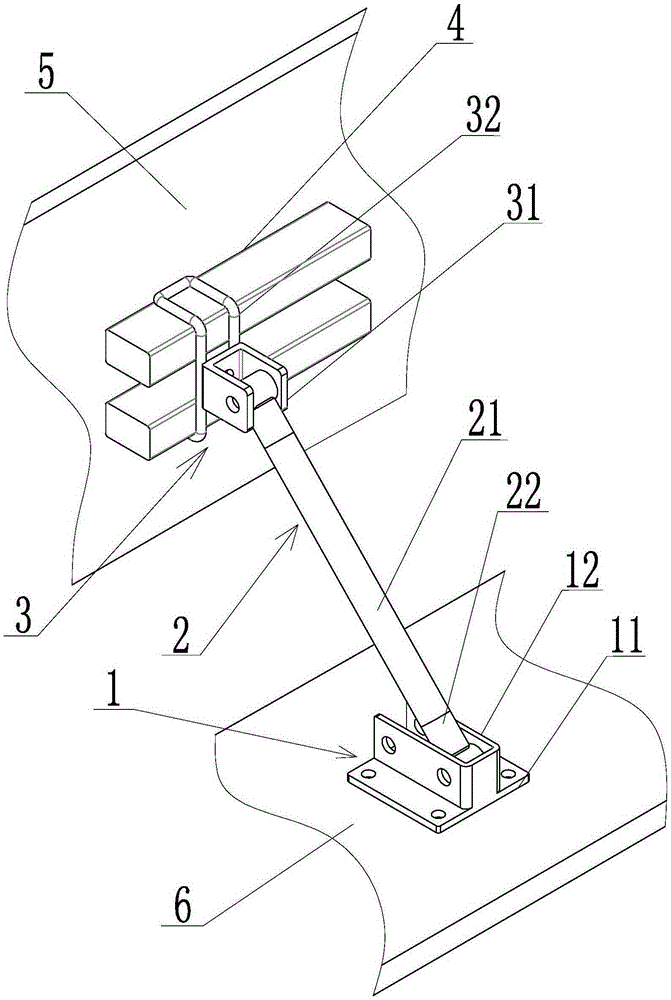

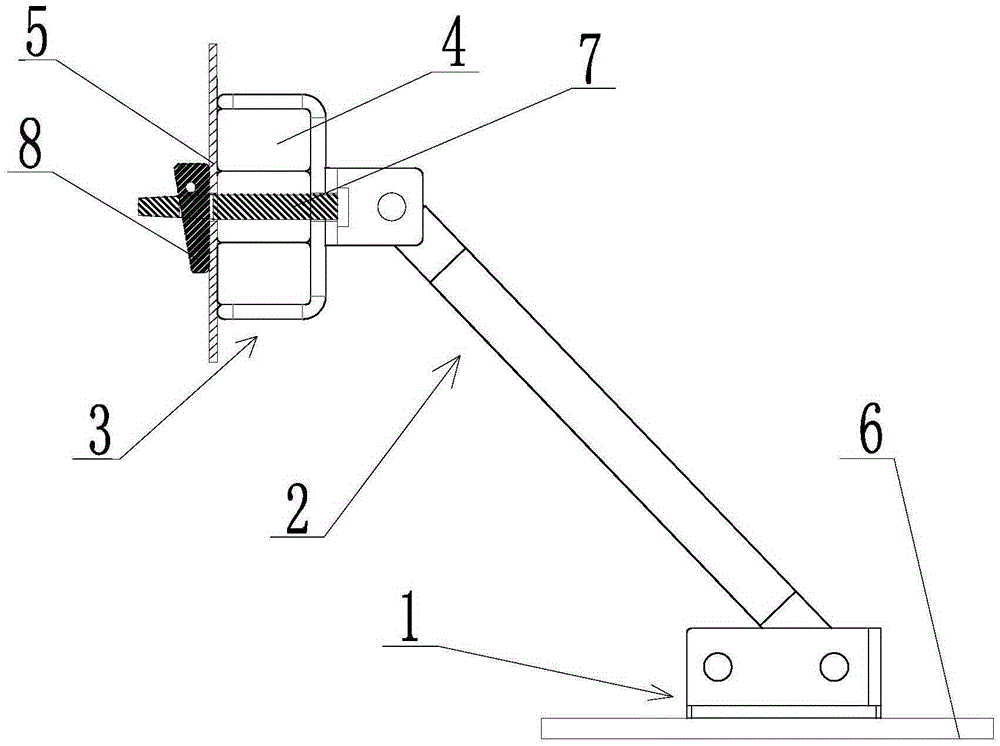

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 The shown foundation pit support structure includes a bottom plate 6, a support base 1, a support rod 2, a support frame 3, a rectangular tube 4 and a guard plate 5, and the support base 1 includes a base plate 11 and a first connecting block 12 , the first connecting block 12 is bent into a U-shape by a steel plate, and the U-shaped end face on one side is welded to the base plate 11 .

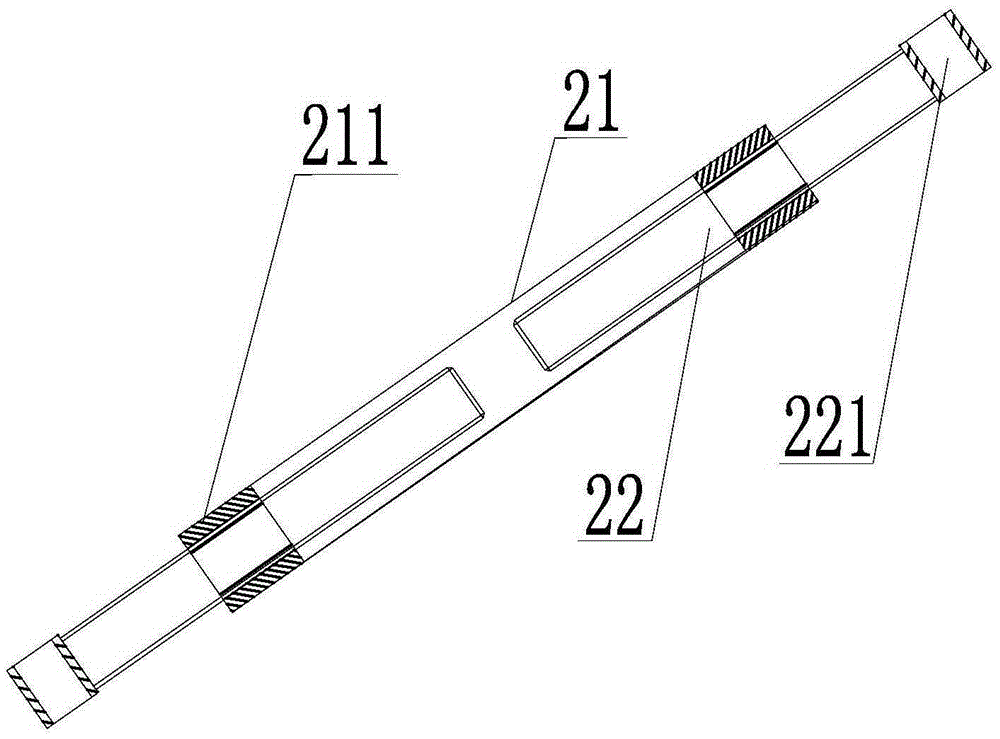

[0018] The support rod 2 includes a rod cover 21 and a telescopic screw 22, the inner walls of the two ends of the rod cover 21 are provided with threads 211, and the two telescopic screws 22 are respectively screwed into the two ends of the rod cover 21, and the telescopic rod 22 is exposed. One end of cover 21 is also provided with a section of circular pipe 221, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com