Cabinet convenient to assemble

A technology for convenient assembly and cabinets, applied in the field of furniture, can solve the problems of reduced firmness and difficulty, and achieve the effects of weight reduction, convenient transportation, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

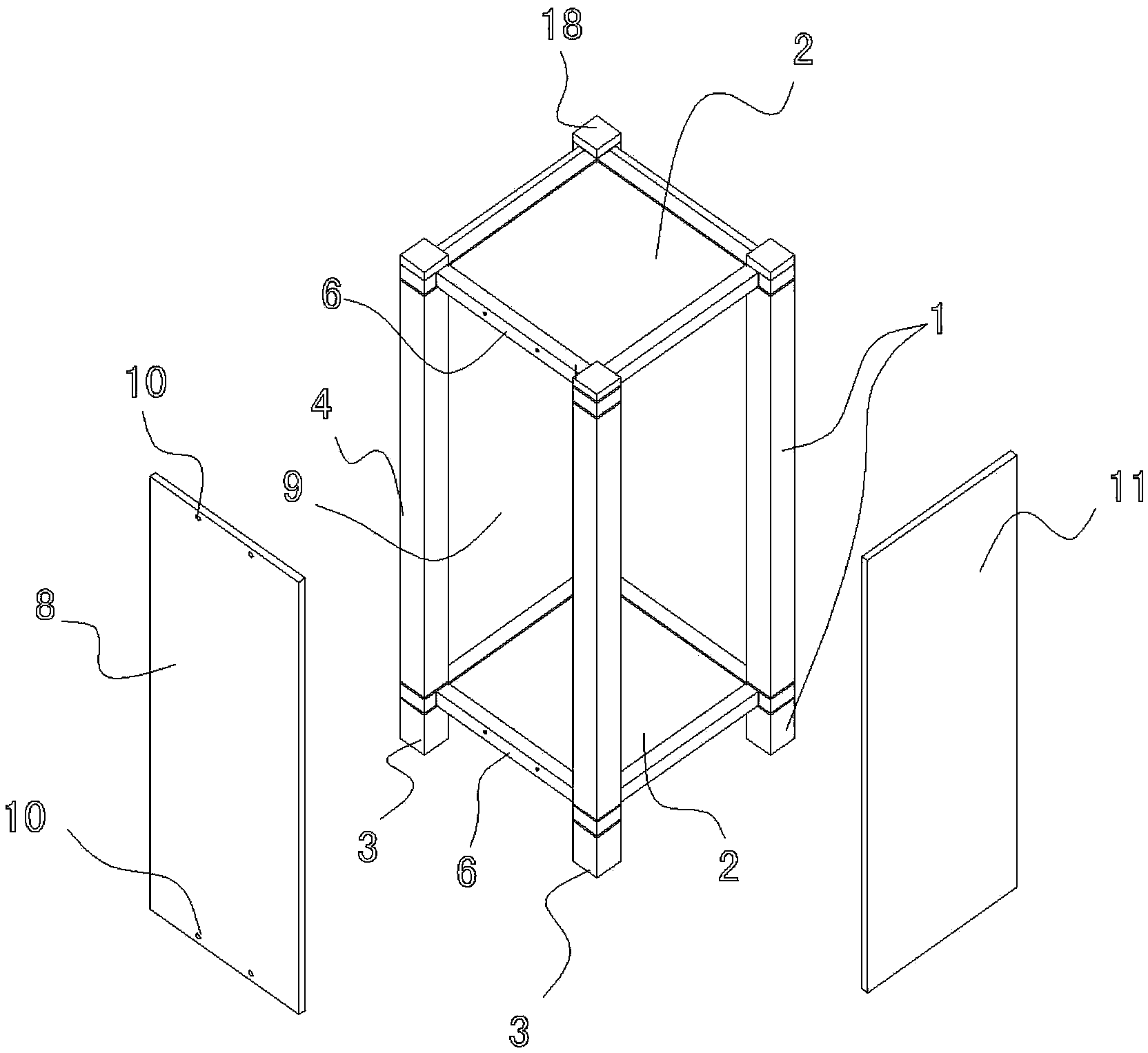

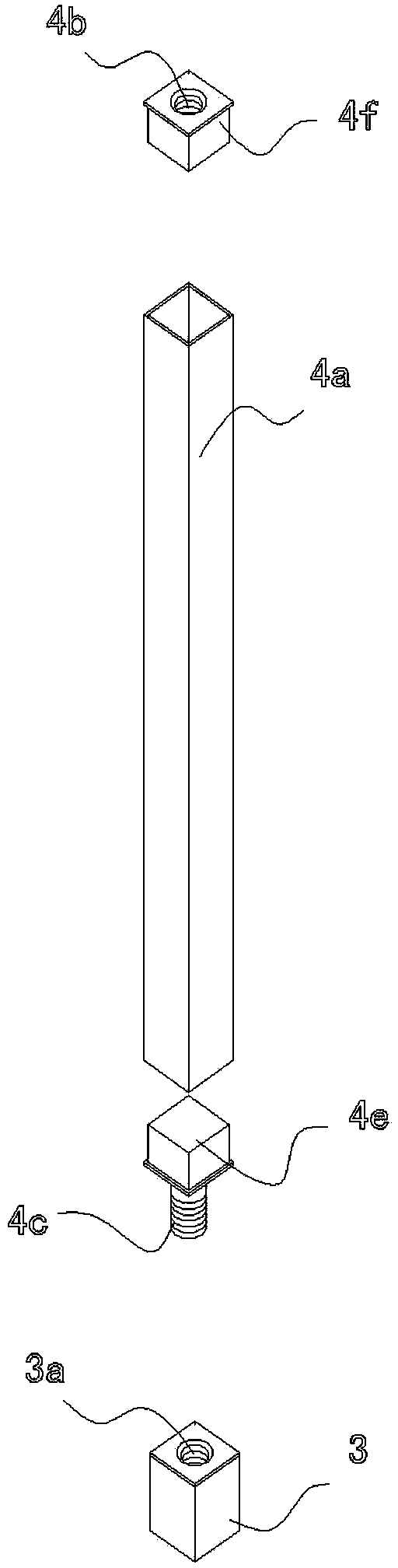

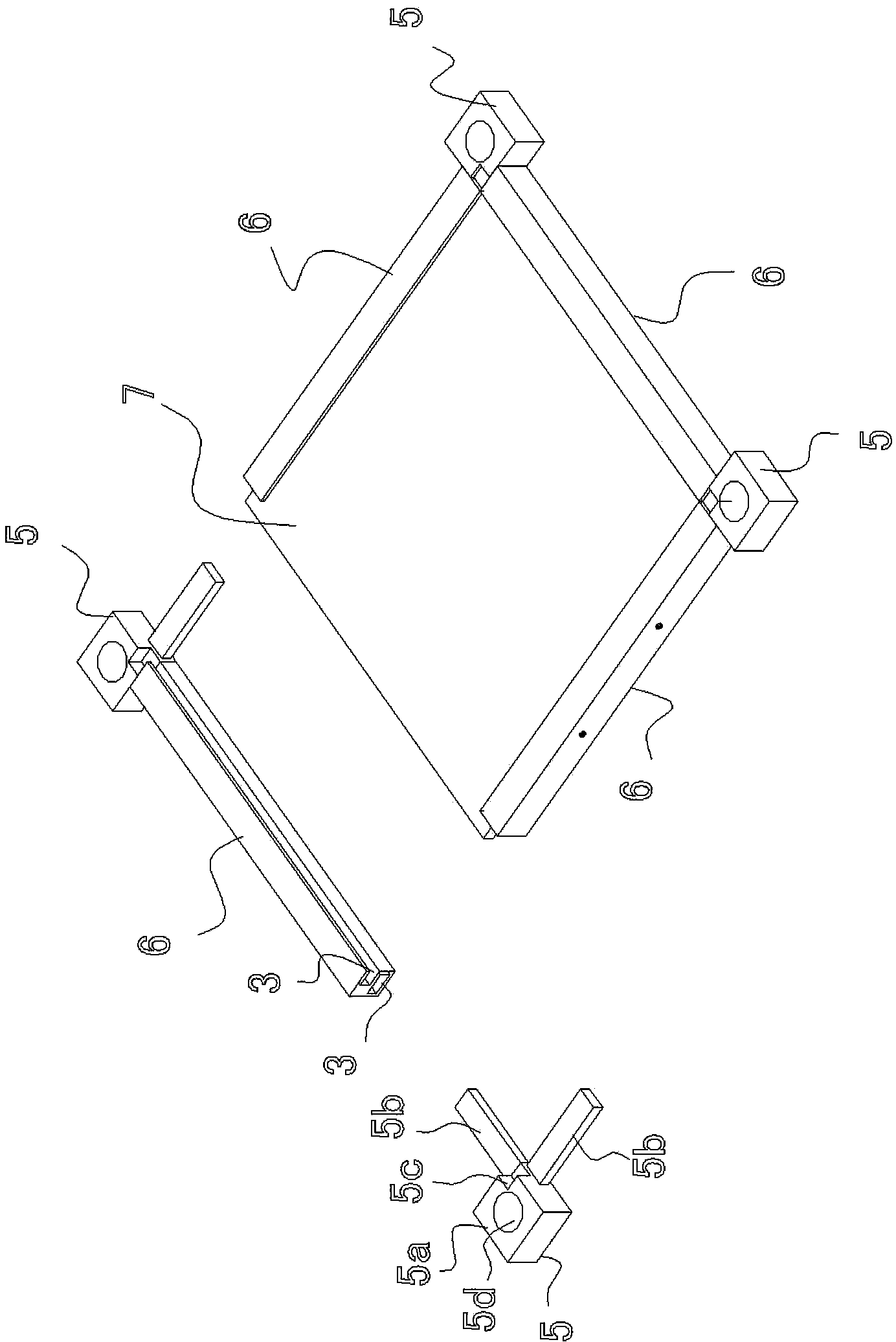

[0018] Embodiment one: if figure 1 , 2 , 3, the present embodiment includes four columns 1 and two panels 2, and its special feature is that the columns 1 include cabinet feet 3 and sub-columns 4 connected to the cabinet feet 3, such as figure 2 As shown, the upper end of the cabinet foot 3 is provided with a screw hole 3a, and the sub-column 4 includes a column body 4a, a screw hole 4b arranged at one end of the column body 4a, and a stud 4c arranged at the other end of the column body 4a, such as image 3 As shown, the panel 2 includes four connectors 5 made of plastic, an aluminum profile 6 connected between the four connectors 5, and a plate 7 made of tempered glass. The connector 5 includes a connector 5a whose upper and lower ends are parallel to each other. , the connecting columns 5b arranged at the side of the connecting body 5a at an angle of 90 degrees to each other, and a falling step 5c on the connecting body 5a between the two connecting columns 5b, the aluminu...

Embodiment 2

[0021] Embodiment 2: as Figure 4 As shown, this embodiment is based on Embodiment 1. The upper end of the cabinet foot 3 is provided with a stud 3b, and the through hole 5d on the connector 5 on one panel 2 is set on the stud of the cabinet foot 3. 3b, the screw hole 4b of the sub-column 4 is screwed on the stud 3b of the cabinet foot 3, and the through hole 5d on the connector 5 of the other panel 2 is set on the stud 4c of the sub-column 4 and fixed by a nut 13 On the stud 4c of the sub-column 4, the panel 2 has n pieces (the embodiment is 3 pieces), n>2, the sub-column 4 has n-1 pieces (the embodiment is 2 pieces), and the nth panel 2 is arranged on The n-2th sub-column 4 and the n-1 sub-column 4 are fixed through the studs 4c and screw holes 4b of the two sub-columns.

Embodiment 3

[0022] Embodiment 3: as Figure 5 As shown, the present embodiment is on the basis of Embodiment 1, is provided with two middle columns 14, the middle columns 14 include the middle cabinet foot 15, the middle sub-column 16 connected on the middle cabinet foot 15, the upper end of the middle cabinet foot 15 Screw holes are provided, and the structure of the middle sub-column 16 is the same as that of the sub-column 4, and also includes a column body, a screw hole arranged at one end of the column body, and a stud column arranged at the other end of the middle column body, such as Image 6 As shown, intermediate connectors 17 are provided on both sides of the middle of the first and second panels 2 corresponding to the bottom end and top end of the intermediate column 16, and the intermediate connectors 17 include intermediate connectors 17a whose upper and lower end surfaces are parallel to each other, and are arranged in a straight line. On the intermediate connecting column 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com