Slide rail mechanism

A technology of slide rail and synchronous mechanism, which is applied in the direction of household appliances, furniture parts, drawers, etc., can solve the problems of reducing effective space, complex structure, left and right shaking, etc., achieves good mute effect, convenient use, and avoids deflection or swinging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

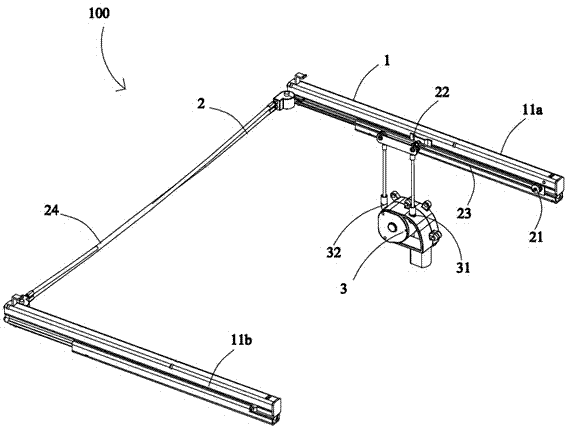

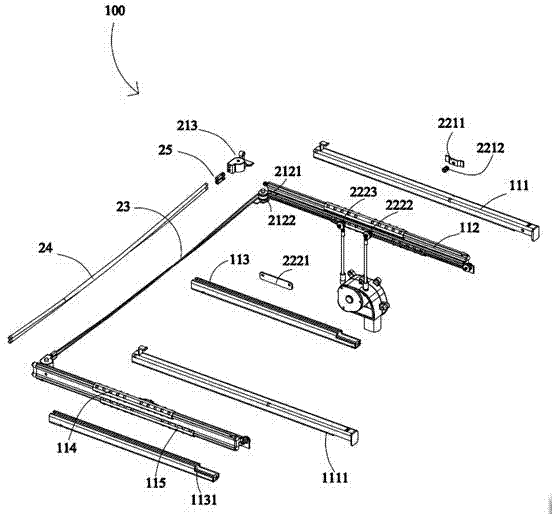

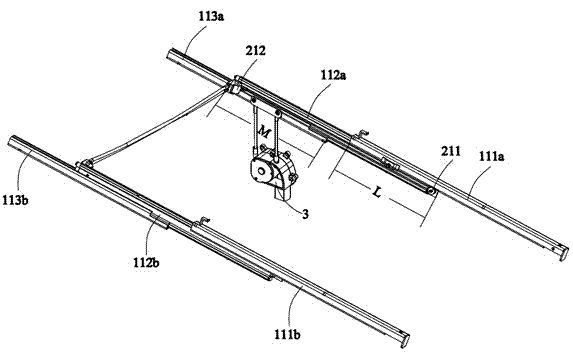

[0023] See Figure 1 to Figure 4 As shown, in order to achieve the above-mentioned object of the invention, the present invention provides a sliding rail mechanism 100 for drawing or pushing a drawer (not shown) in a box (not shown), including two sets of sliding rails arranged oppositely. Component 1, the synchronization mechanism 2 and the motor component 3 that make the two sets of slide rail components 1 keep moving synchronously. Of course, the slide rail mechanism 100 can also be used for drawing, expanding or contracting other structures. The sliding rail mechanism 100 cooperates with the motor assembly 3 and the synchronization mechanism 2 so that the sliding rail assembly 1 keeps moving synchronously, realizes automation, and is convenie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com