A kind of preparation method and application of ternary composite material

A technology for composite materials and preparation steps, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, water/sludge/sewage treatment, etc., can solve the problems of large specific surface energy, reduced catalytic activity, Prone to agglomeration and other problems, to achieve the effect of avoiding agglomeration and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

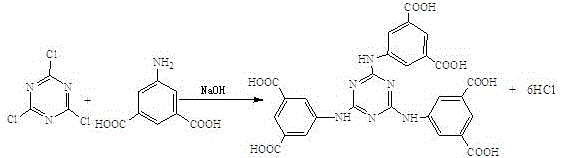

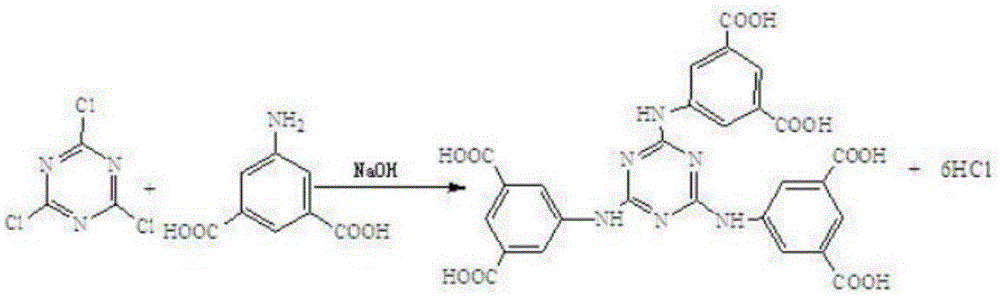

[0029] A kind of cyanuric cyanuric acid hexavalent carboxylic acid ligand H 6 The preparation method of L: take 23.0g of 5-aminoterephthalic acid, 12.0g of sodium hydroxide and 200mL of water, stir for 30min, add 8.0g of cyanuric chloride, 40mL of 1,4-dioxane, and heat to reflux for 8h , adjust the pH=2 with hydrochloric acid, filter with suction and wash the solid 3 times with distilled water, and dry the solid to obtain the ligand H 6 L; Yield rate is 95%; Chemical formula is C 3 N 3 (NH) 3 (C 6 h 3 ) 3 (COOH) 6 , the molecular formula is C 27 h 18 N 6 o 12 .

Embodiment 2

[0031] A kind of cyanuric cyanuric acid hexavalent carboxylic acid ligand H 6The preparation method of L: take 25.0g of 5-aminoterephthalic acid, 15.0g of sodium hydroxide and 200mL of water, stir for 30min, add 8.5g of cyanuric chloride, 50mL of 1,4-dioxane, and heat to reflux for 10h , adjust the pH=2 with hydrochloric acid, filter with suction and wash the solid 3 times with distilled water, and dry the solid to obtain the ligand H 6 L; Productive rate is 95%; Chemical formula is with embodiment 1, and molecular formula is with embodiment 1.

Embodiment 3

[0033] A kind of cyanuric cyanuric acid hexavalent carboxylic acid ligand H 6 The preparation method of L: take 24g of 5-aminoterephthalic acid, 13.5g of sodium hydroxide and 200mL of water, stir for 30min, add 8.25g of cyanuric chloride, 45mL of 1,4-dioxane, heat and reflux for 9h, Adjust the pH to 2 with hydrochloric acid, filter with suction and wash the solid 3 times with distilled water, and dry the solid to obtain the ligand H 6 L; Productive rate is 95%; Chemical formula is with embodiment 1, and molecular formula is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com