Small-sized brushing machine

A brushing machine, a small-scale technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of manual brushing with high labor intensity, waste of manual spraying materials, low efficiency, etc., and achieve novel and unique structure. Simple, low labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

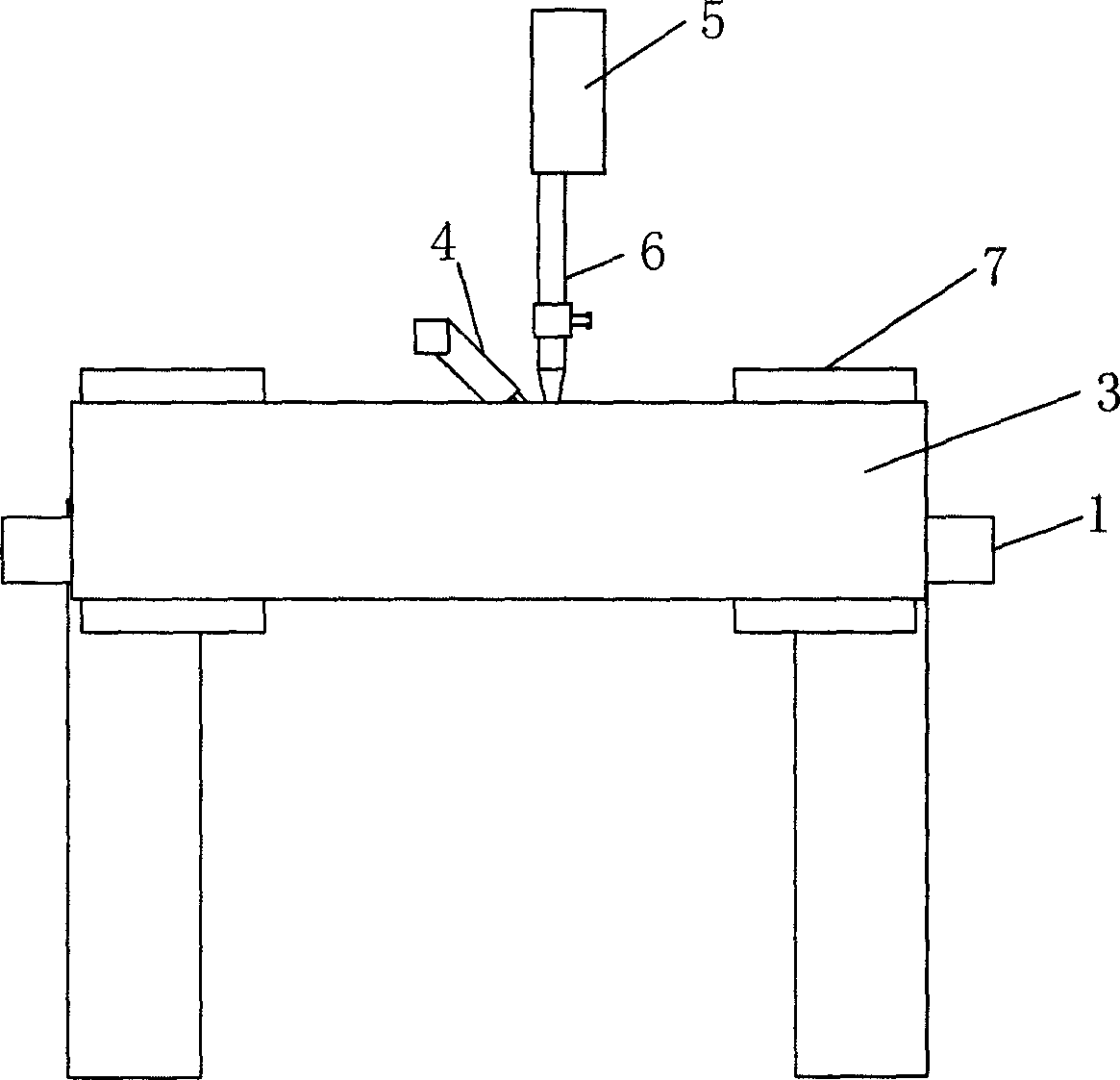

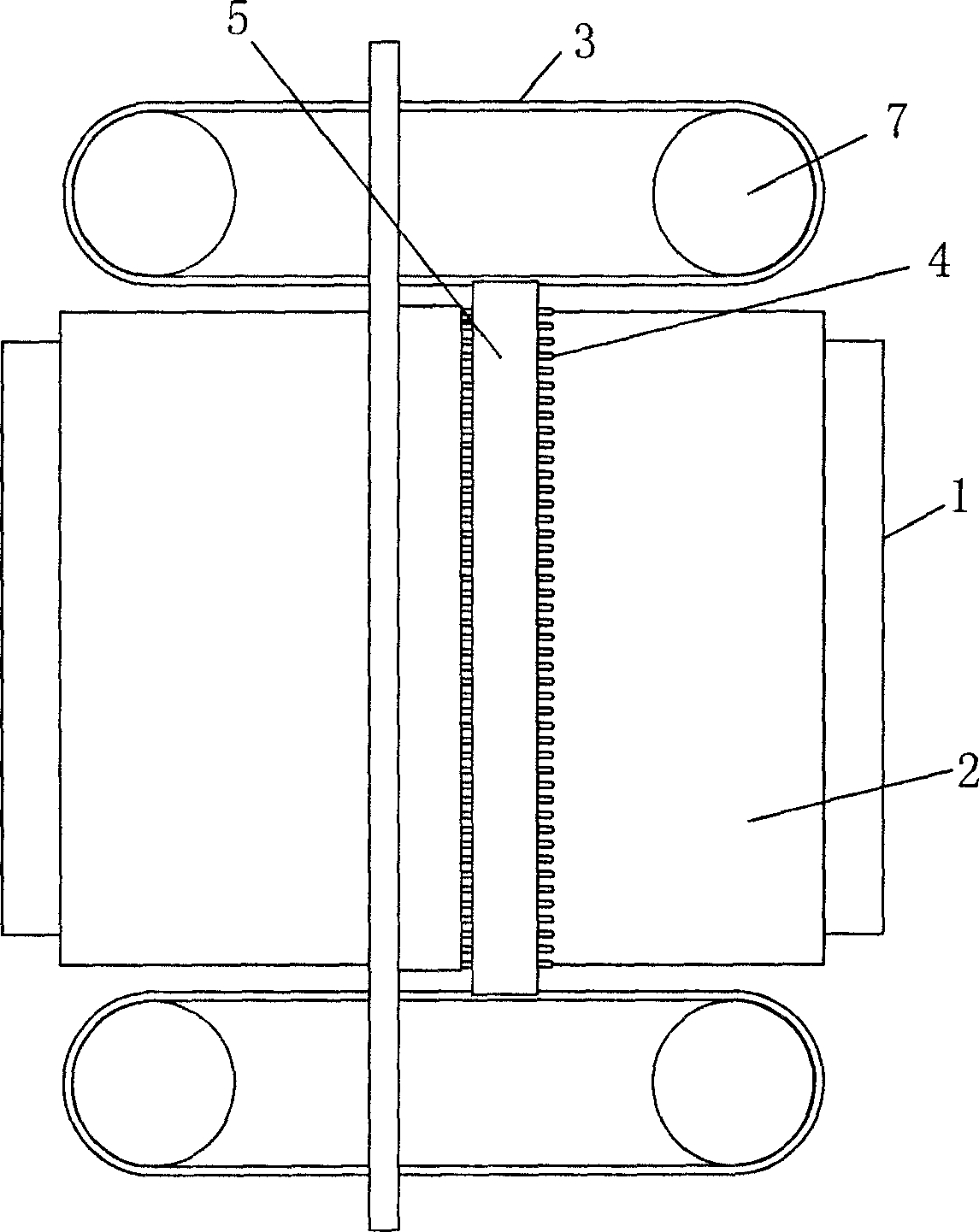

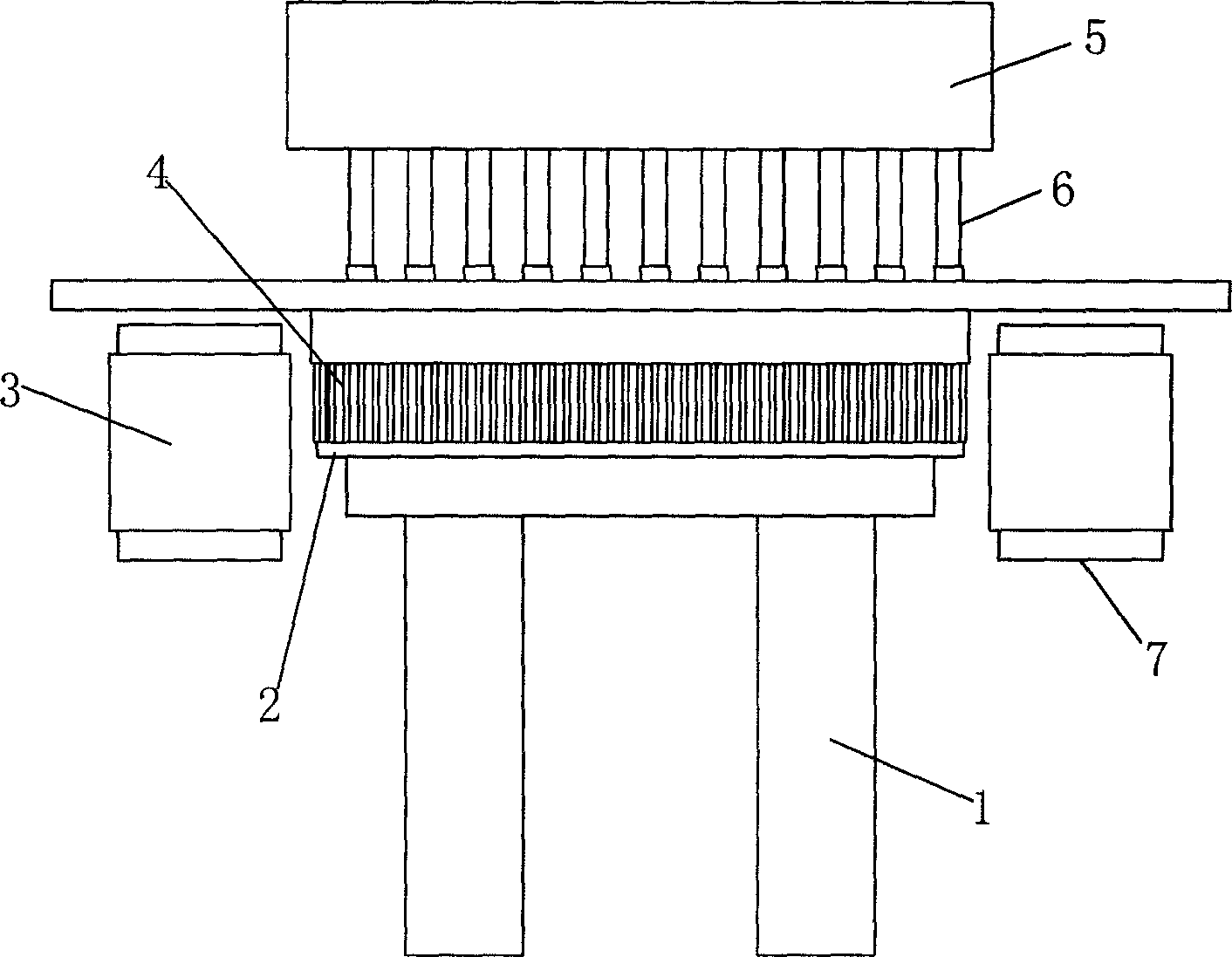

[0011] Depend on Figure 1 to Figure 4 Given, the present invention comprises a frame 1, the upper surface of the frame 1 is provided with a bottom plate 2 with a smooth upper surface protruding from the left and right ends of the frame 1, and the left and right sides of the bottom plate 2 are respectively provided with a conveyor belt with a conveying surface facing the side of the bottom plate 2 3. A wool row brush 4 inclined towards the conveying direction of the conveyor belt 3 is arranged above the bottom plate 2, a paint box 5 is arranged above the wool row brush 4, and a plurality of burettes 6 are arranged on the paint box 5 at intervals along the axial direction of the wool row brush 4, The lower end of the burette 6 is placed above the wool part of the wool row brush 4, and the conveyor belt 3 is driven by a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com