Gating system with multistage split transverse runners

A pouring system and sprue technology, applied in the directions of casting mold composition, casting molding equipment, casting molten material container, etc., can solve the problem of different runner flow rate and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings of the description.

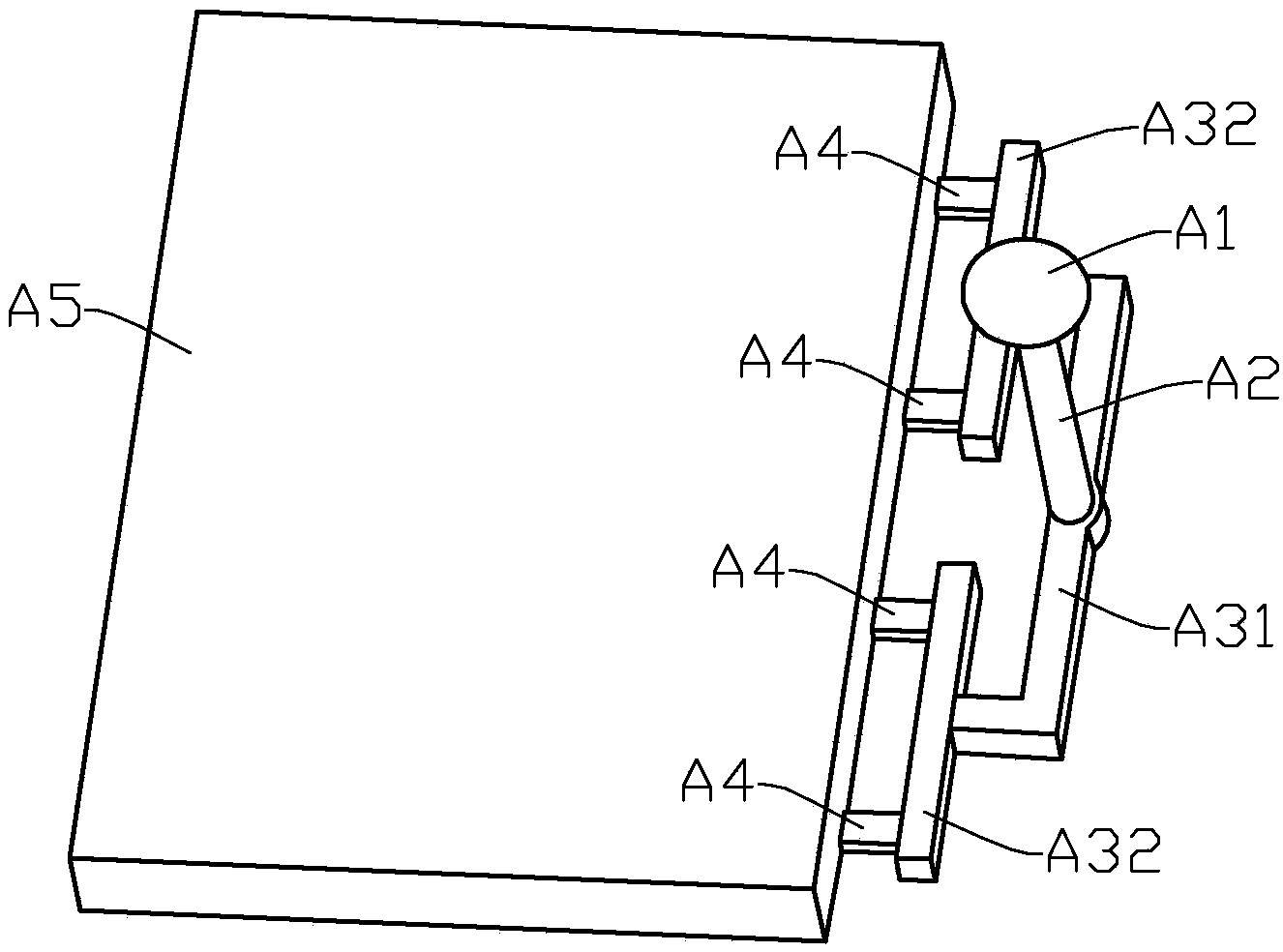

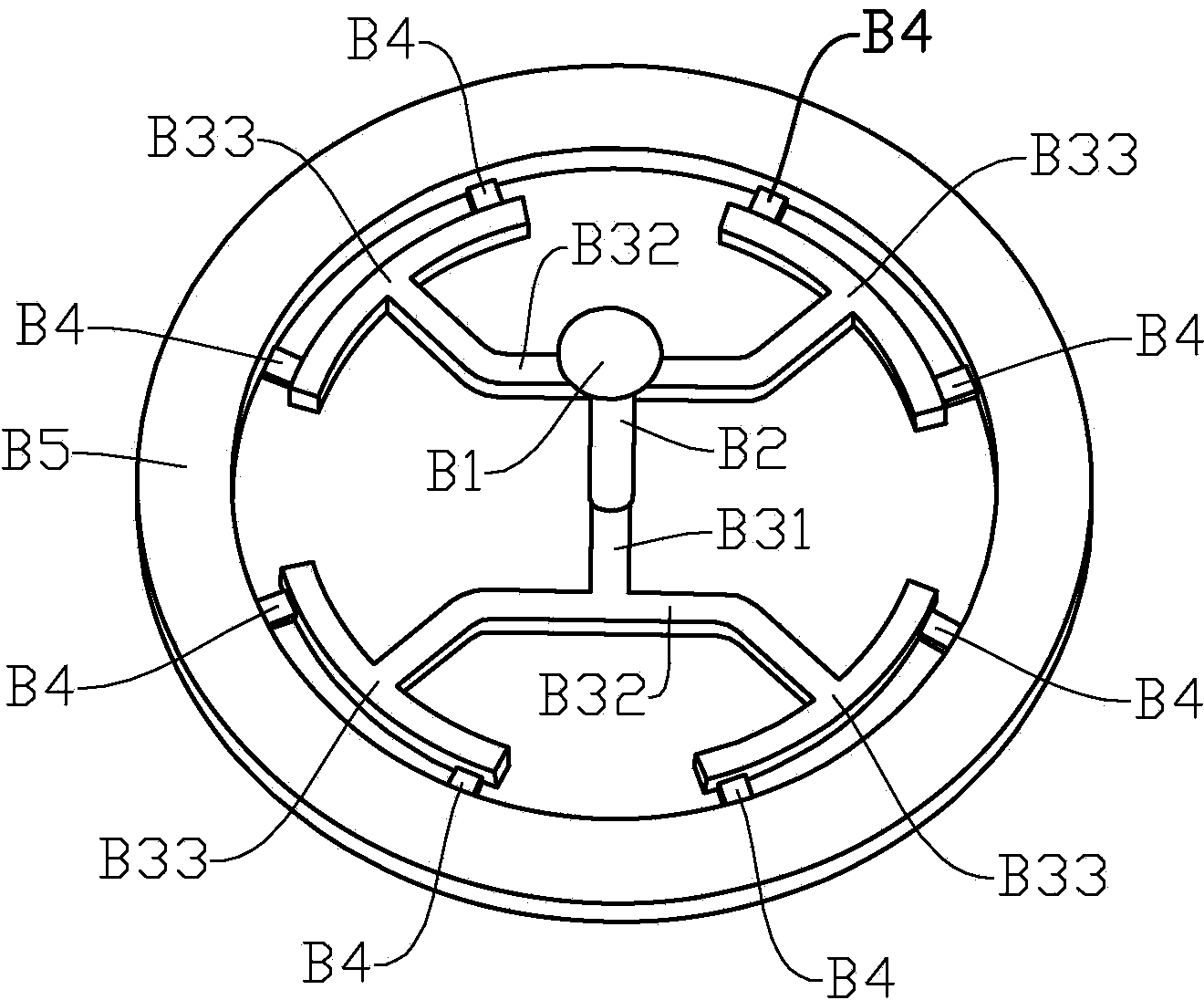

[0028] The gating system with the multi-stage split runner of the present invention includes a sprue cup, a sprue, a runner and an inner runner, and the runner includes at least two stages; each runner of each stage The midpoint of the runner is set as the split point, and the midpoint of the first-stage runner corresponds to the straight runner; each runner of each stage is symmetrically connected to two next-stage runners relative to the midpoint of the runner. Runner, the runner of the next level is perpendicular to the junction of the runner of the previous level; each runner of the last level is symmetrically connected with two inner runners relative to the midpoint of the runner, and the inner runner It is perpendicular to the connection with the last level runner.

[0029] The present invention utilizes the principle of symmetry and adopts th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com