Trademark cutting mechanism

A cutting mechanism and trademark technology, which is applied in metal processing and other directions, can solve the problems that the cutting machine is too simple and cannot be used for batch processing of trademarks, etc., and achieves the effect of easy implementation, simple structure and precise adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

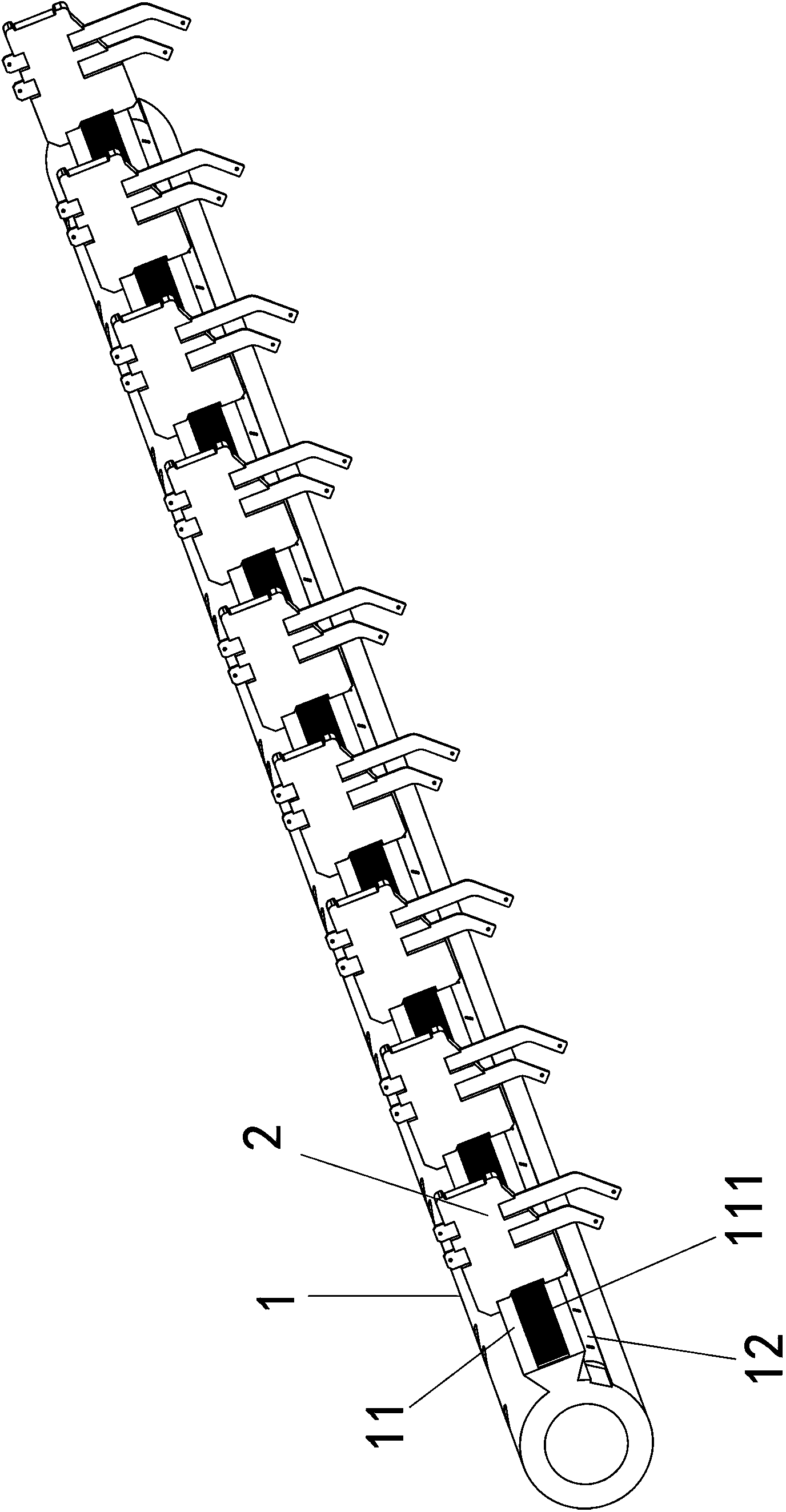

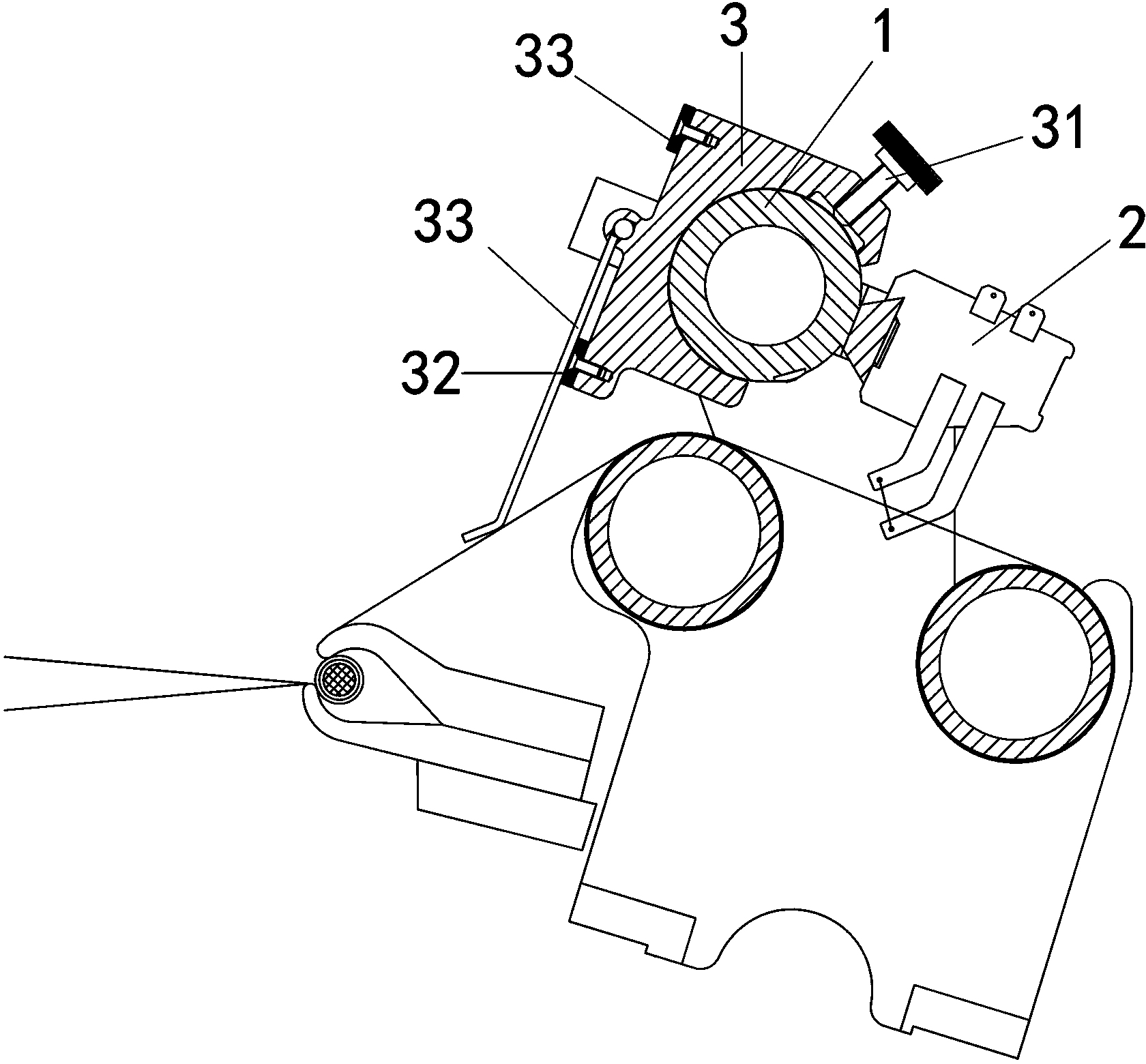

[0027] Example: such as Figure 1-3 As shown, a trademark cutting mechanism includes a knife rest 1, and a slide rail 11 extending along the length direction of the knife rest 1 is provided on the knife rest 1; a plurality of side-by-side cutters 2 are slidably connected to the slide rail 11.

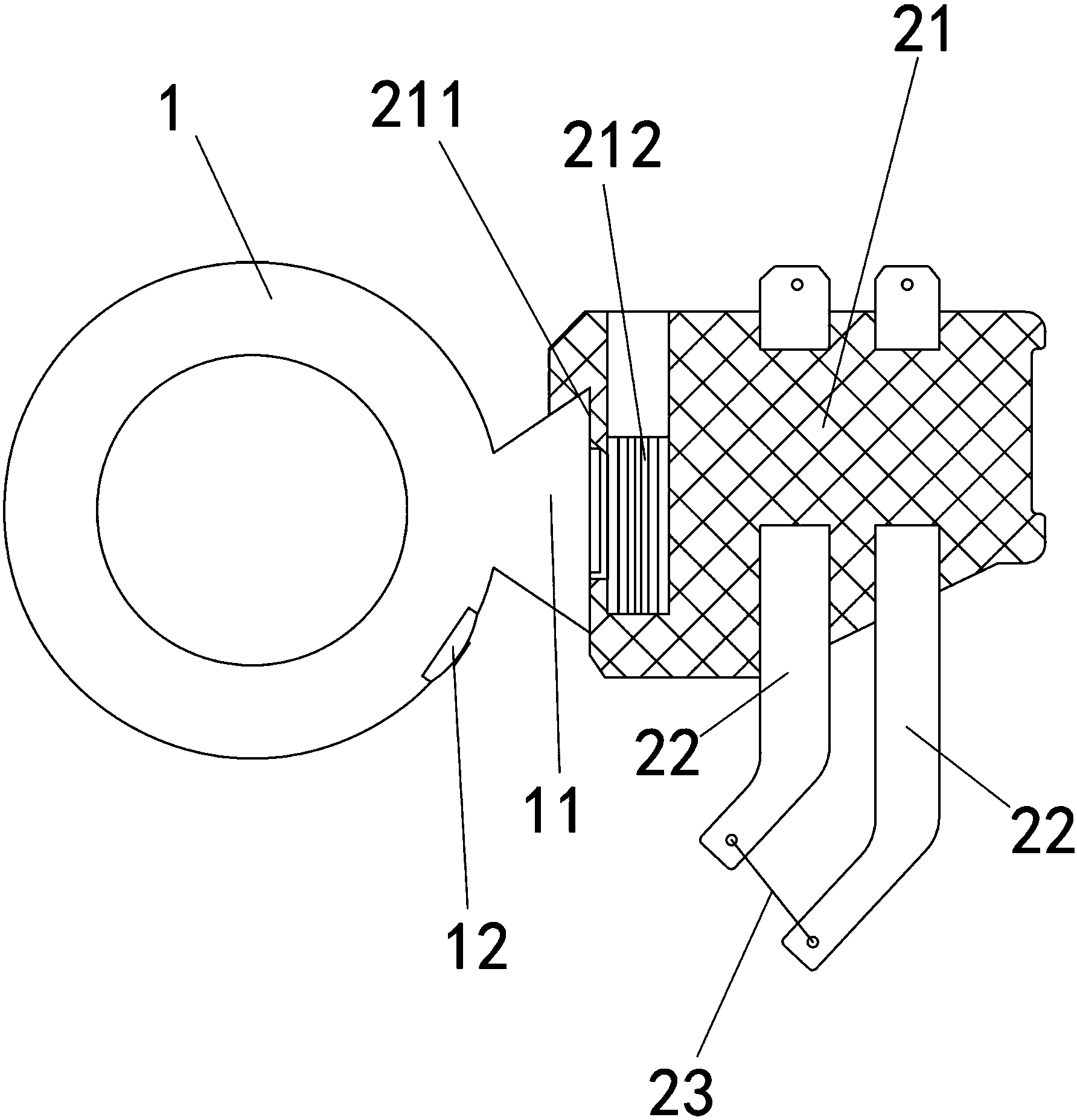

[0028] The cutter 2 includes a knife seat 21 on which two electrode sheets 22 are arranged, and a heating wire 23 for cutting trademarks is electrically connected between the lower ends of the two electrode sheets 22 .

[0029] The knife seat 21 is provided with a socket 211 which is slidably socketed on the slide rail 11; the cross section of the slide rail 11 is dovetail-shaped; the shape of the socket 211 matches the slide rail 11; A rack 111 is provided; the knife holder 21 is rotatably connected with an adjustment column 212 capable of engaging the rack 111; a notch should be provided on the upper end of the adjustment column 212 to facilitate the application of specific tools, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com