Hydraulic shock absorber and method for realizing safe turning of vehicle based on articulation system

A technology of hydraulic shock absorber and articulation system, applied in the field of hydraulic shock absorber, can solve the problems of vehicle trailer, inertial tail drift, etc., and achieve the effect of light and fast rotation and comfortable driving experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

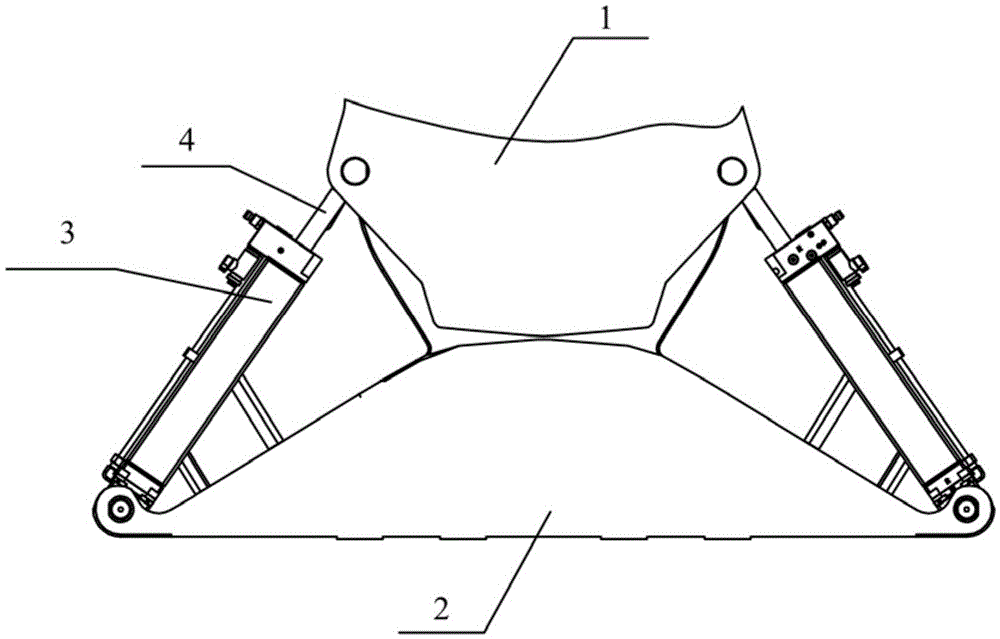

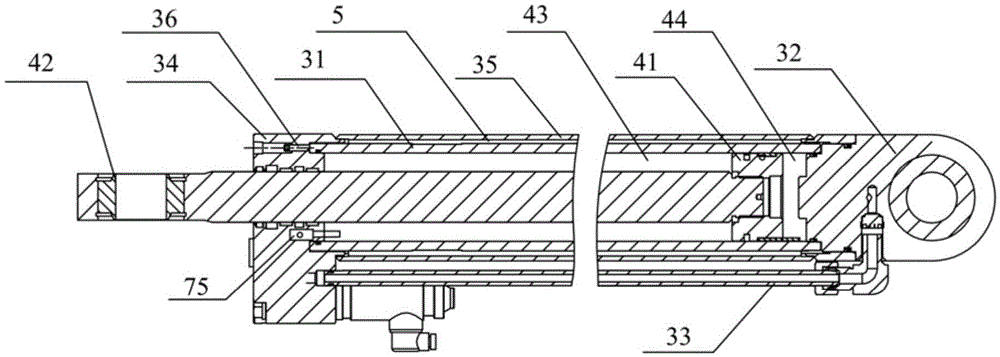

[0108] In one embodiment of the present invention, as figure 1 As shown, a stepped damping buffer is connected between the front frame 1 and the rear frame 2 of the hinge system, and each stepped damping buffer includes a hydraulic control oil circuit, a cylinder assembly 3, a piston assembly 4 and an oil storage tank 5, Among them, the hydraulic control oil circuit, the cylinder assembly 3 and the oil storage tank 5 are fixedly connected, and then connected with the rear frame 2 of the hinge system; the piston assembly 4 is connected with the front frame 1 of the hinge system, and the piston assembly 4 is arranged on the cylinder assembly 3 and can slide in the cylinder assembly 3.

[0109] 1) Components of the hydraulic control circuit

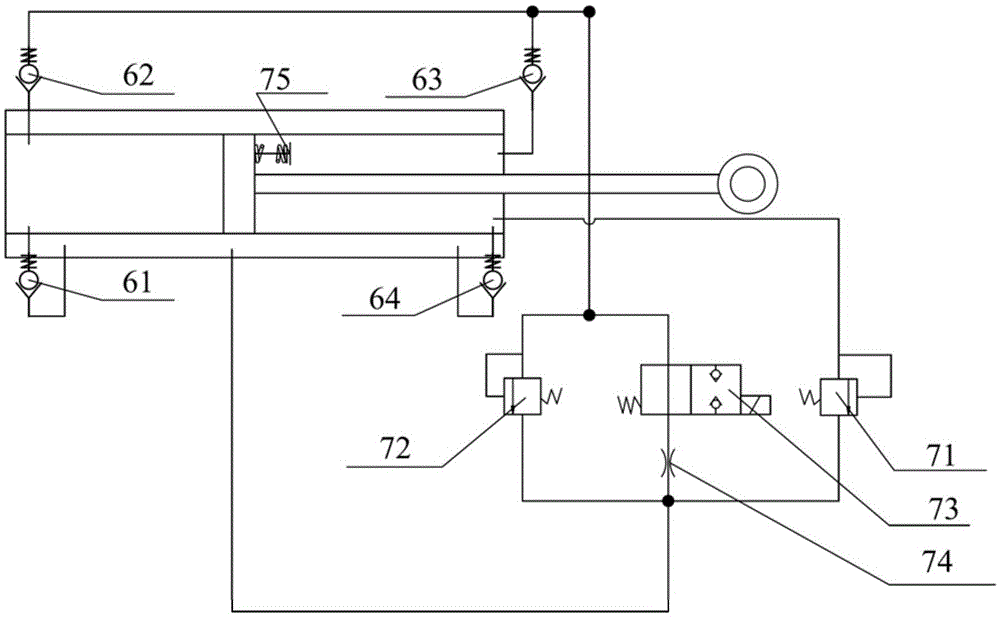

[0110] Such as figure 2 As shown, it is a structural schematic d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com