Enhanced rotary resistance level controller

An enhanced controller technology, applied in large containers, containers, rigid containers, etc., can solve the problem that the enhanced anti-rotation level controller is easily damaged by materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

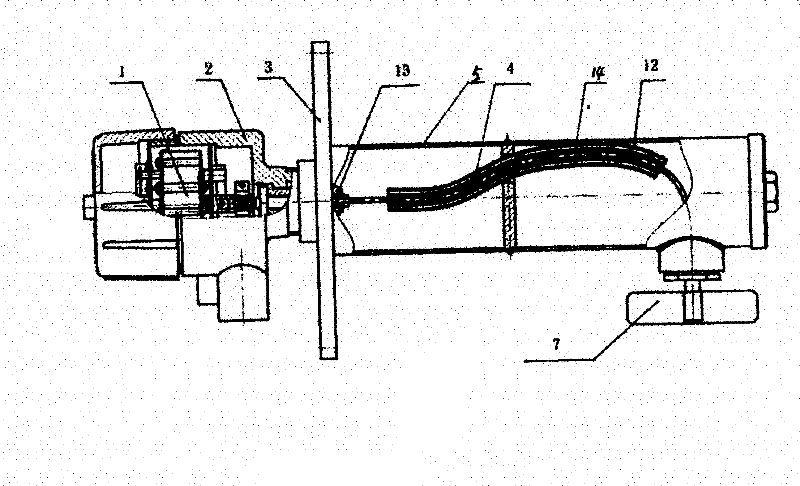

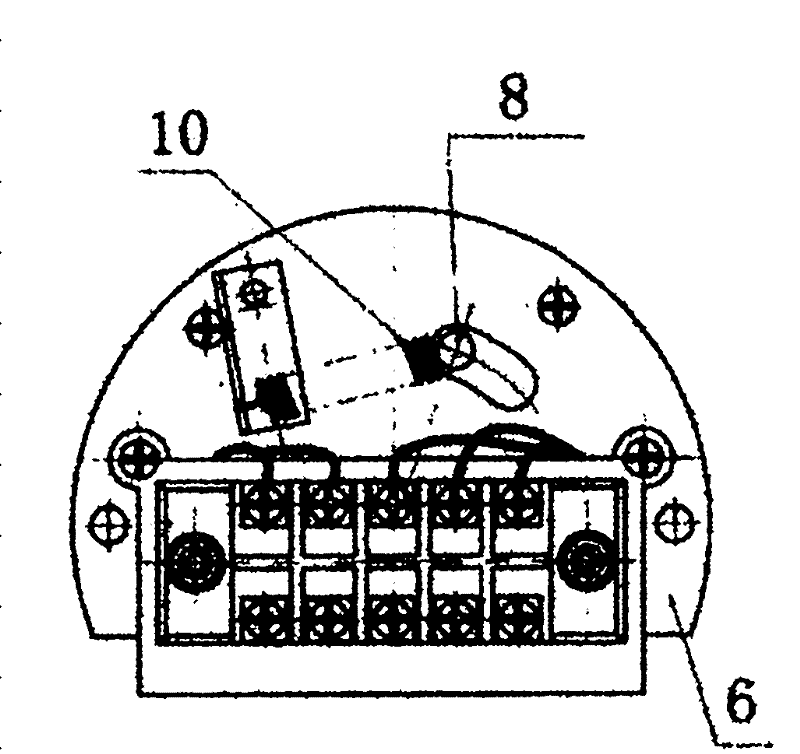

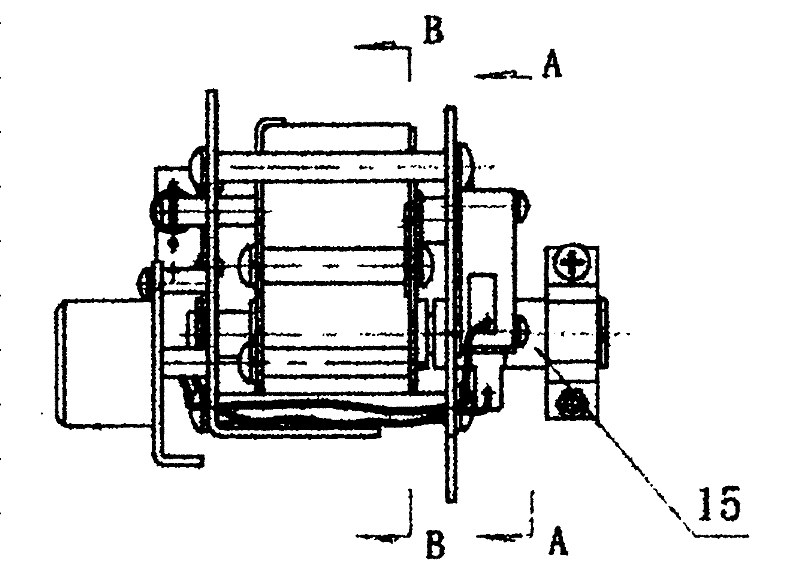

[0025] Such as Figure 1-Figure 4 , a reinforced anti-rotation level controller, including a geared motor 1, a housing 2 with a geared motor 1 inside and a housing 5 with a flexible shaft 4 inside, and the geared motor 1 and the housing 5 are respectively set On both sides of the mounting flange 3, a supporting plate 6 is set in the housing 2, the output shaft 13 of the geared motor 1 is connected to one end of the flexible shaft 4 in the housing 5, and the other end of the flexible shaft 4 is connected to the housing The outer rotor 7 of the 5 is connected, and the housing of the geared motor 1 is vertically provided with an adjustment shaft 8, and one end of the adjustment shaft 8 passes through the supporting plate 6, and the supporting plate 6 is provided with an alarm micro switch 9, and the supporting plate 6 is provided with an alarm micro switch 9. A tension spring 10, the tension spring 10 pulls the adjustment shaft 8, so that the adjustment shaft 8 contacts the alarm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com