Infrared focal plane array blind pixel detection method and device

A technology of infrared focal plane and detection method, which can be used in measurement devices, radiation pyrometry, optical radiation measurement, etc., and can solve problems such as poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

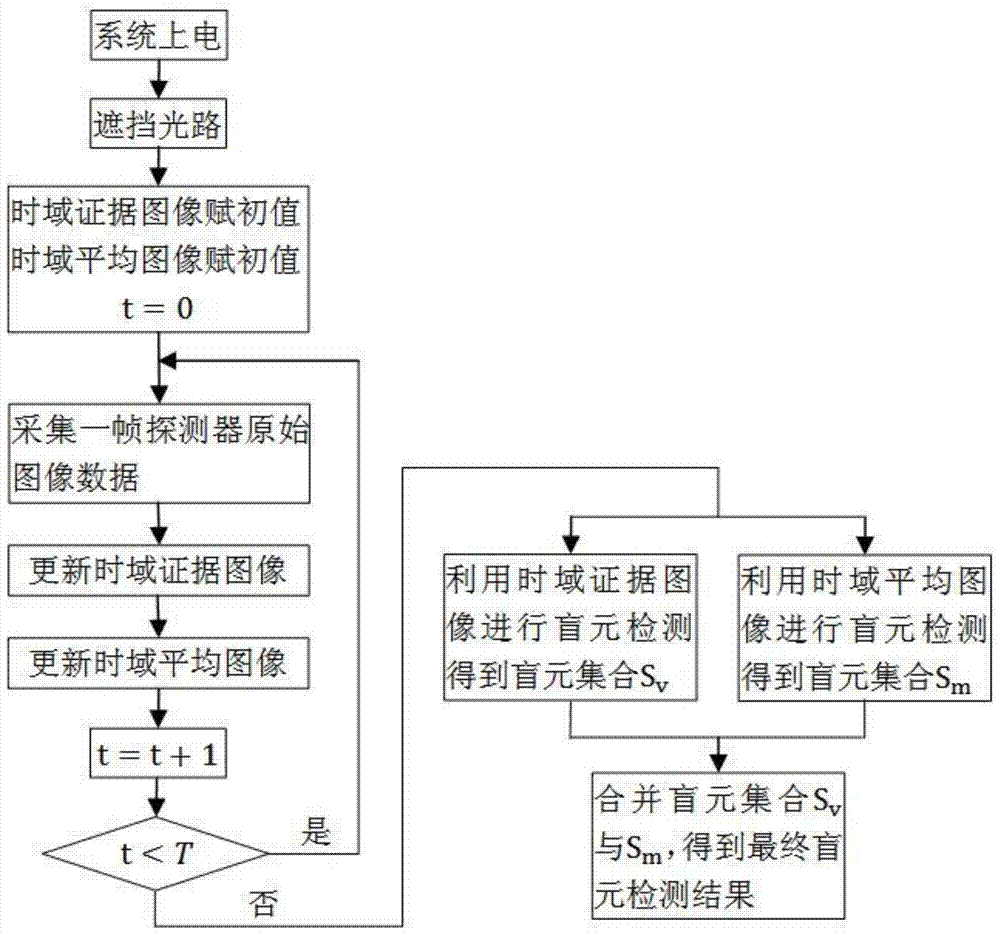

[0039] The basic scheme of the blind element detection method of infrared focal plane array is as follows:

[0040] Initialization step: Power on the infrared system and block the light path;

[0041] Sequential acquisition steps: each acquisition of a frame of detector raw image data I t , t is currently the number of acquisitions;

[0042]Processing steps after each acquisition: After each acquisition, add a window to each pixel as the center in turn, and calculate the local mean value μ of the pixels in the neighborhood of the set range of the pixel local and the local standard deviation σ local , if the pixel and the local mean μ local The difference is greater than three times the local standard deviation σ local , the pixel is counted correspondingly; at the same time, the original image data It is superimposed;

[0043] Blind element judgment step: After collecting T times, the corresponding count value of the pixel is counted, and if the corresponding count value ...

Embodiment 2

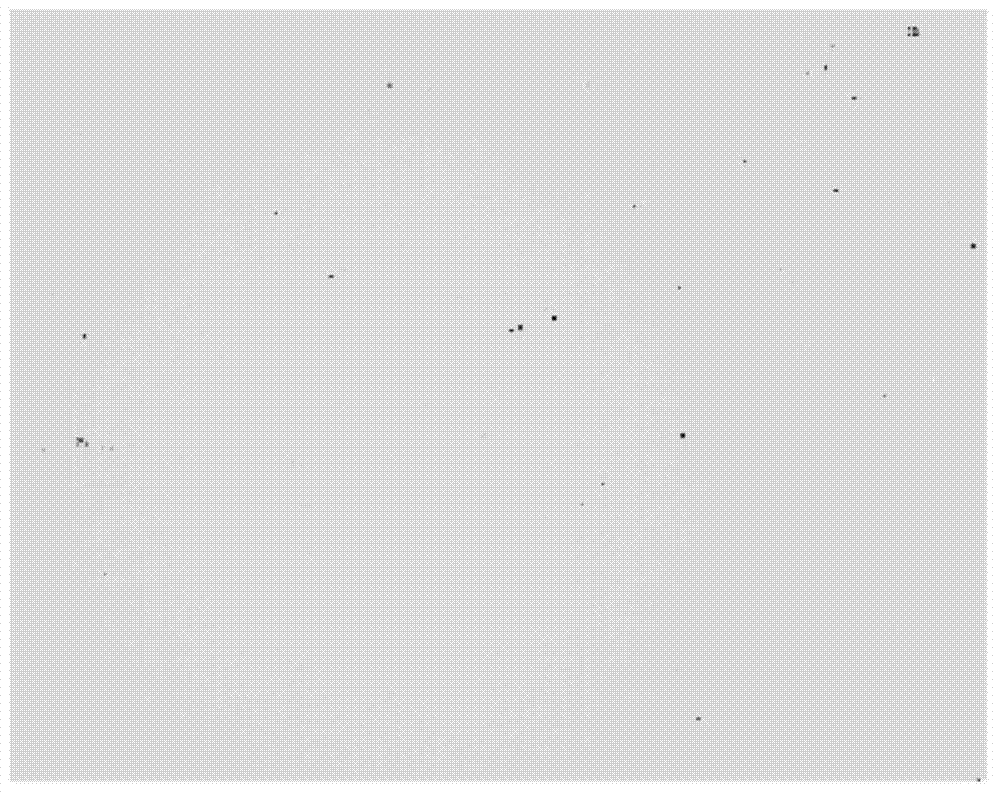

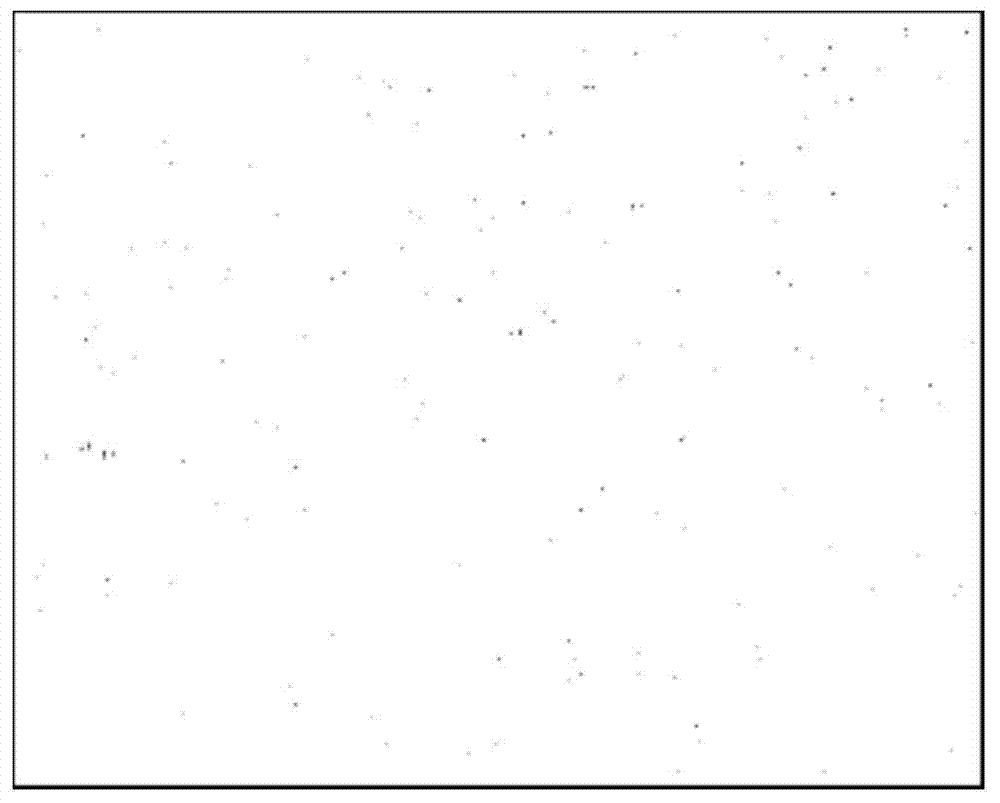

[0047] The infrared imaging system adopted in this embodiment can use a medium-wave cooled focal plane array detector with an area array size of 320×256. The image processing circuit of the imaging system is composed of FPGA and DSP, and the FPGA performs the processing of the original image data of the detector. Collection, the distribution range of data is [-32768, 32767], DSP performs subsequent processing, and the blind element detection process is implemented in DSP.

[0048] refer to figure 1 , the specific implementation steps of the whole embodiment are as follows:

[0049] Step 1: After the infrared imaging system is powered on, the light path is blocked by command control shutter.

[0050] Step 2, assign an initial value to the time-domain evidence image, namely E v (i, j)=0, assign an initial value to the time-domain average image, namely E m (i, j)=0, (i, j) is the pixel coordinates, the initial value is assigned to the loop count, that is, t=0, then, the loop s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com