Special tool for electrification fastening of 10-kilovolt pin insulator

A technology of pin-type insulators and special tools, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of inconvenient tightening process, the detachment of the fixing nut from the screw, the drop of the pin-type insulator, etc., to achieve high work efficiency and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

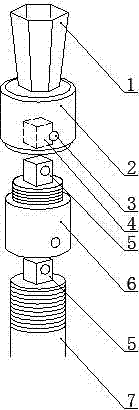

[0010] Example: such as figure 1 As shown, the live fastening 10 kV pin insulator special tool includes an insulating rod 7, the upper part of the insulating rod is provided with an external thread, and a plug 5 is provided, and the lower end of the connector 6 is open and provided with an internal thread, which is screwed with the upper end of the insulating rod 7. A plug 5 is also arranged at the upper end of the connector 6 . A slot 4 is arranged on the lower end surface of the sleeve 2, a hexagonal screw hole is arranged on the upper end surface, and a nut cover 1 is arranged on the hexagonal screw hole outer cover.

[0011] The nut cover 1 is a hexagonal prism with an open upper end, the upper port of the hexagonal prism is larger than the lower port, and the size of the lower port is the same as the aforementioned hexagonal screw hole. Each side of the lower port is fixedly connected with each side of the hexagonal screw hole.

[0012] The sleeve 2 and the connector 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com