Amorphous ribbon cutting machine

A technology of amorphous strip and cutting machine, which is applied to the attachment of shears, shearing devices, shearing equipment, etc., can solve problems such as poor workmanship, difficult cleaning, and damage to blades, and achieve high production accuracy and production efficiency. High and long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

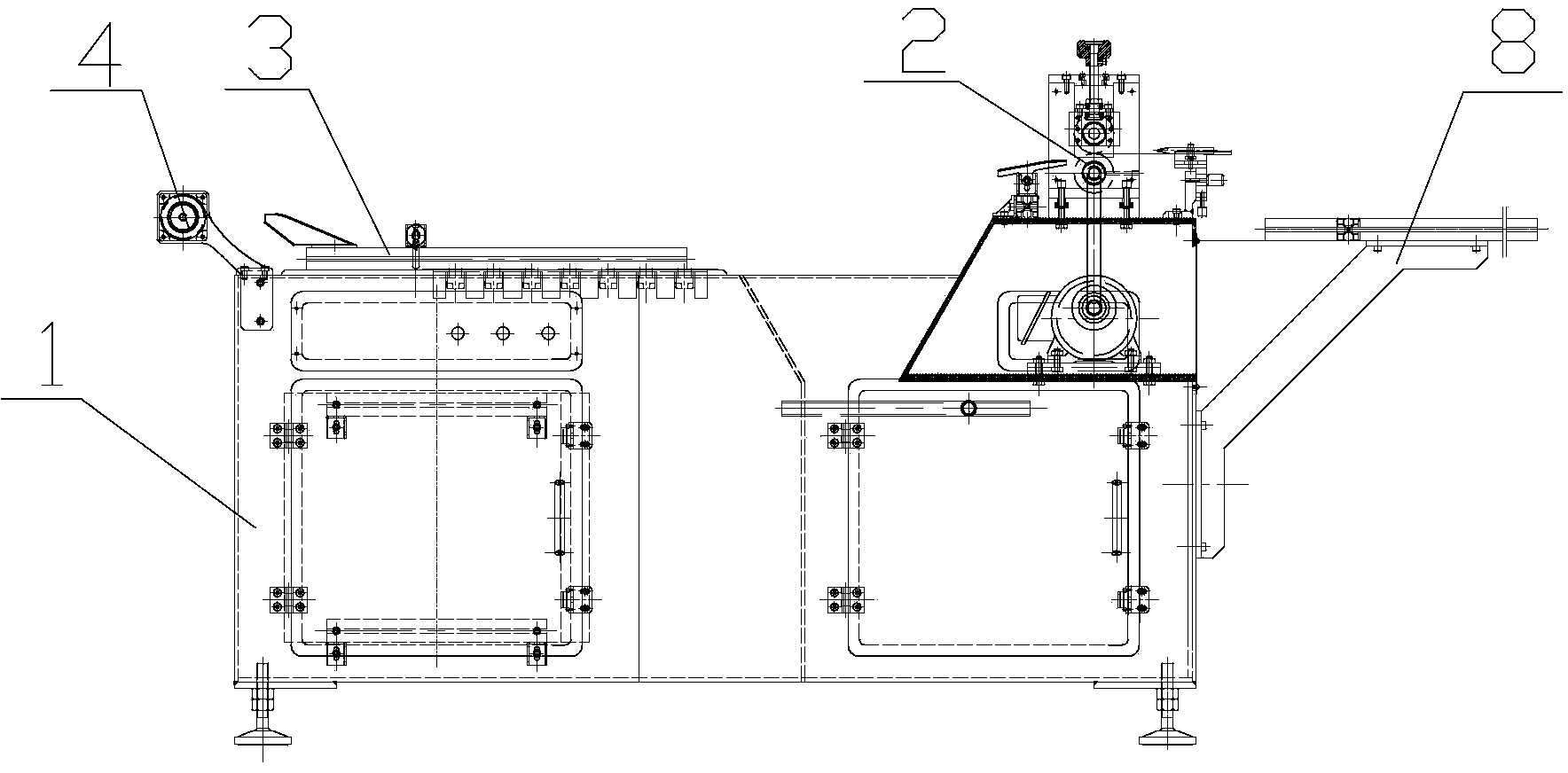

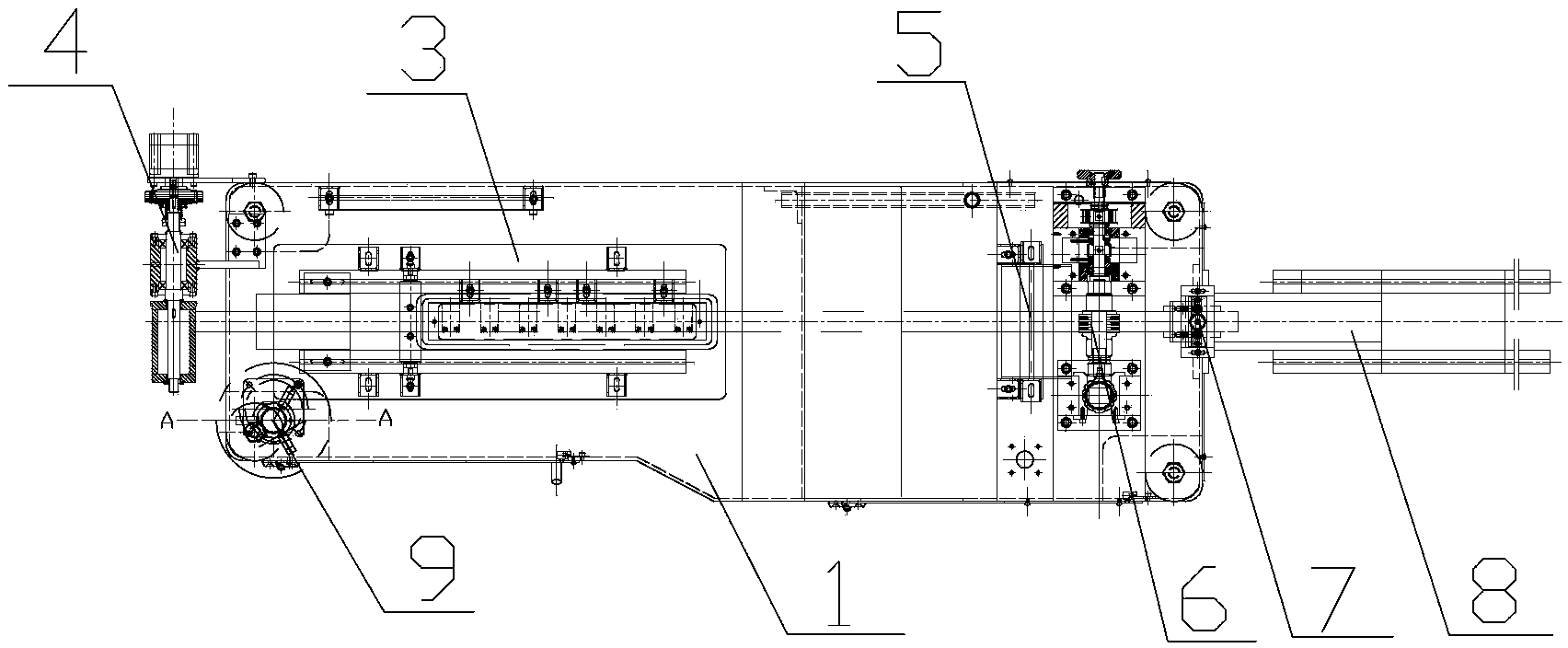

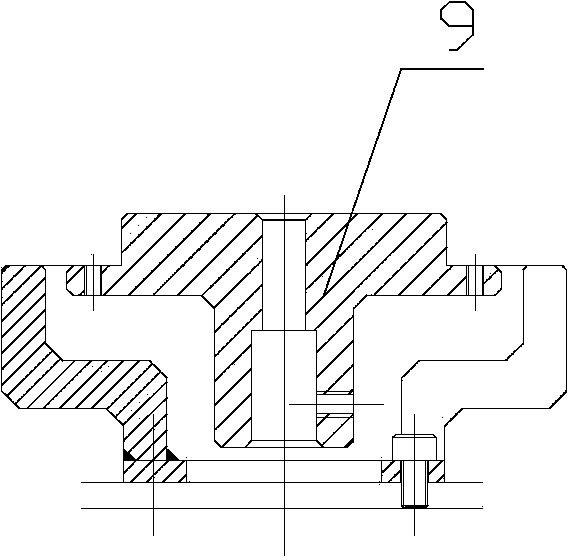

[0043] A kind of amorphous strip cutting machine, the structure is as Figure 1 ~ Figure 3 As shown, the cutting machine includes a box body 1, a feeding bracket device 8, a feeding positioning device 7, a hob device 6, a guiding device 5, a tape winding device 4, a tightening device 9, an induction device 3 and a transmission device 2, and the feeding device The bracket device 8, the feeding positioning device 7, the hob device 6 and the guide device 5 are sequentially arranged on one side of the box body 1 from the outside to the inside, and the tape winding device 4, the tightening device 9 and the induction device 3 are arranged on the box body in sequence from the outside to the inside. On the other side of the body 1, the transmission device 2 is connected with the hob device 6;

[0044] After the amorphous tape passes through the feeding support device 8 and the feeding positioning device 7 in sequence, the hob device 6 cuts the amorphous tape, and the cut amorphous tap...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap