Gear burnishing fixture used for sleeve gears of synchronizers

A technology of synchronizers and gear sleeves, which is applied to components with teeth, gear teeth manufacturing devices, gear teeth, etc., can solve the problems of low processing efficiency, inconvenient installation and disassembly, and only one gear sleeve can be processed at a time. High processing efficiency and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

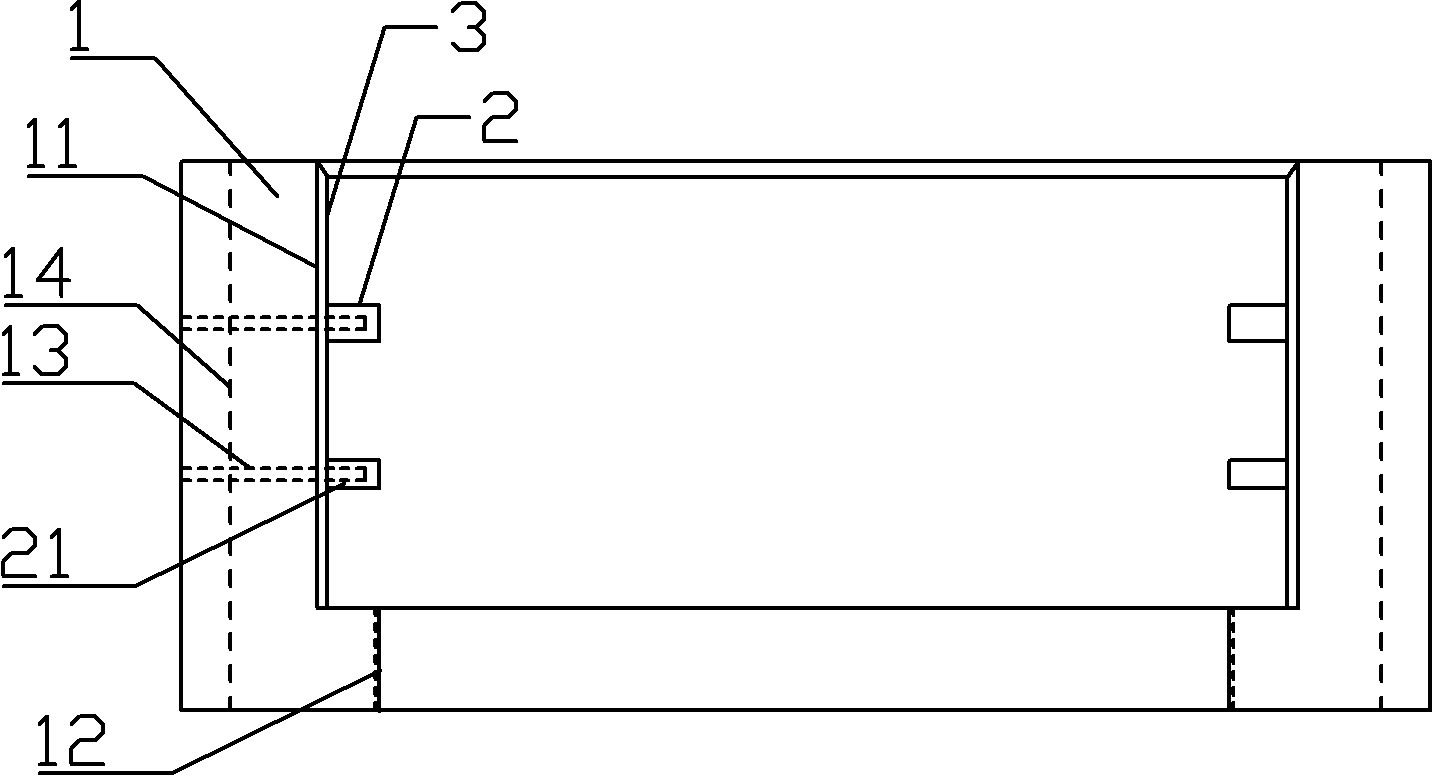

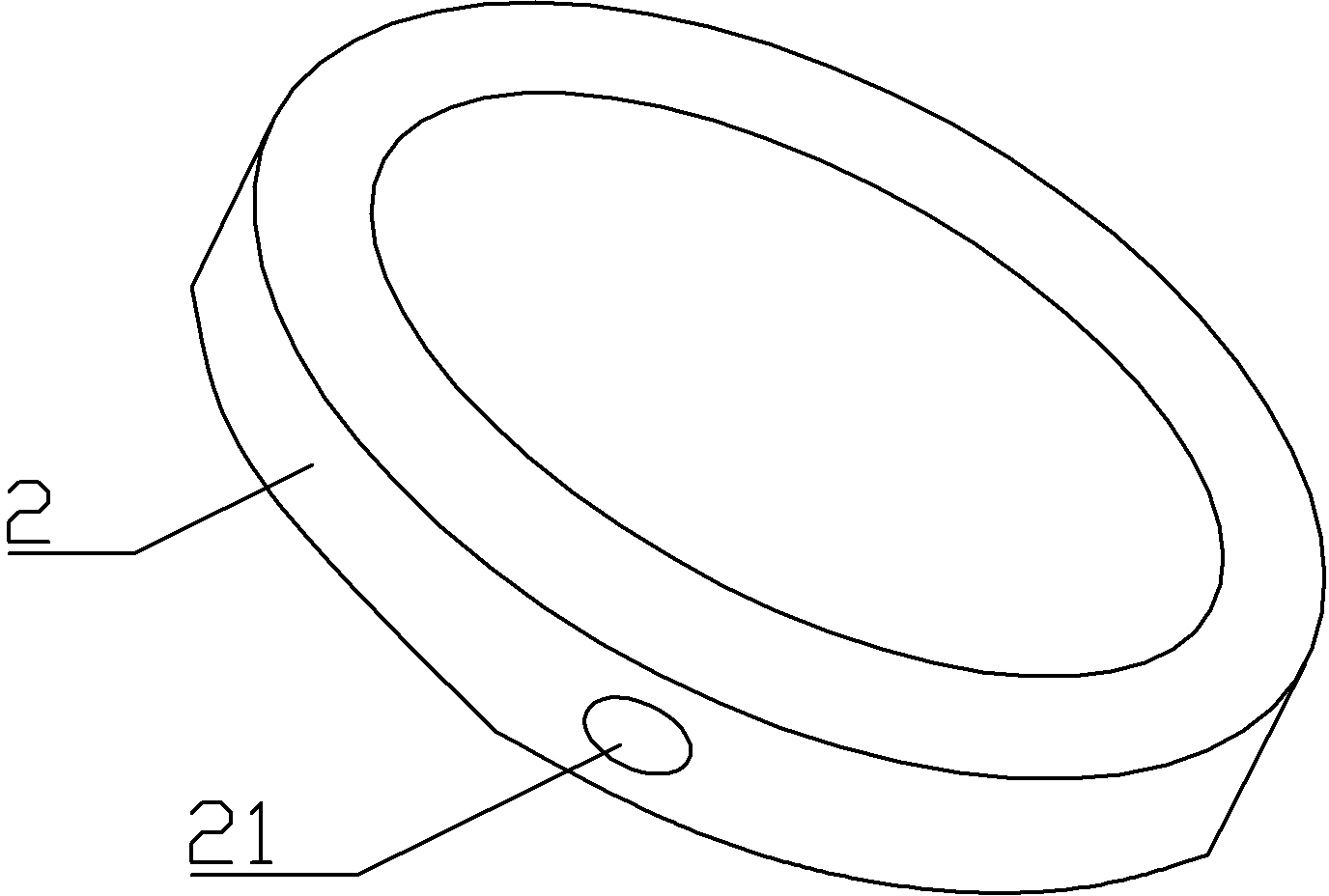

[0012] like figure 1 The tooth extrusion fixture for the synchronizer gear sleeve shown includes a positioning plate 1, an upper ring surface 11, a lower ring surface 12, a threaded hole 13, a groove 14, an annular pressure plate 2, a threaded column groove 21, and an annular friction plate 3.

[0013] The inner circle of the positioning disc 1 has an upper annular surface 11 and a lower annular surface 12, the inner circle of the lower annular surface 12 is provided with threads, the upper annular surface 11 and the lower annular surface 12 are stepped, and the upper annular surface 11 and the lower annular surface 12 The step between is the supporting portion for placing the tooth sleeve, and three threaded holes 13 are evenly distributed in the circumferential direction of the positioning plate 1, and two grooves 14 are evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com