Sealing strip mold and mold machining process

A mold processing and sealing strip technology, applied in the field of mold processing and structural design, can solve problems such as narrow space, drilling burrs, uneven parting, etc., and achieve the effect of improving the pass rate, avoiding scrapping, and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

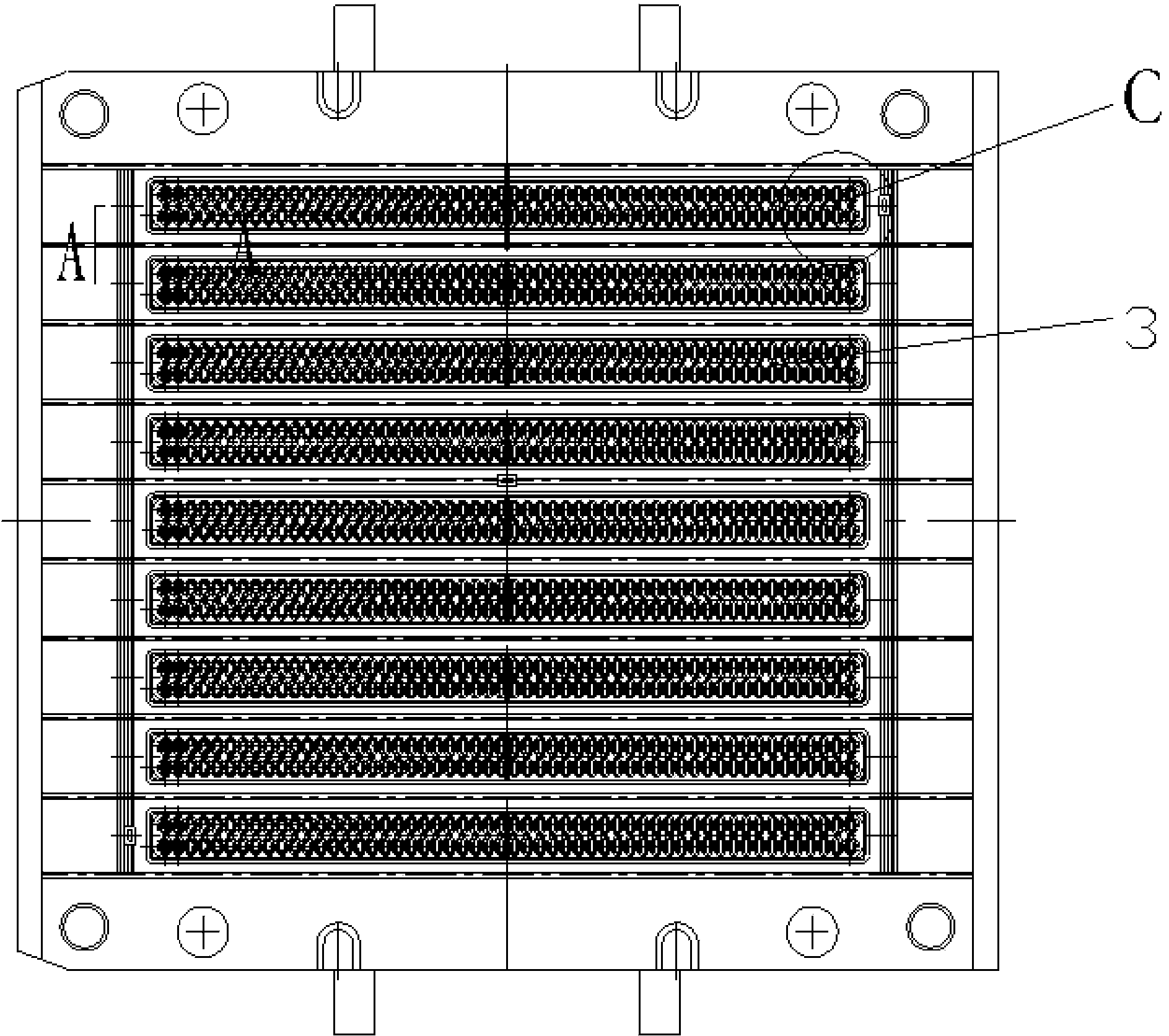

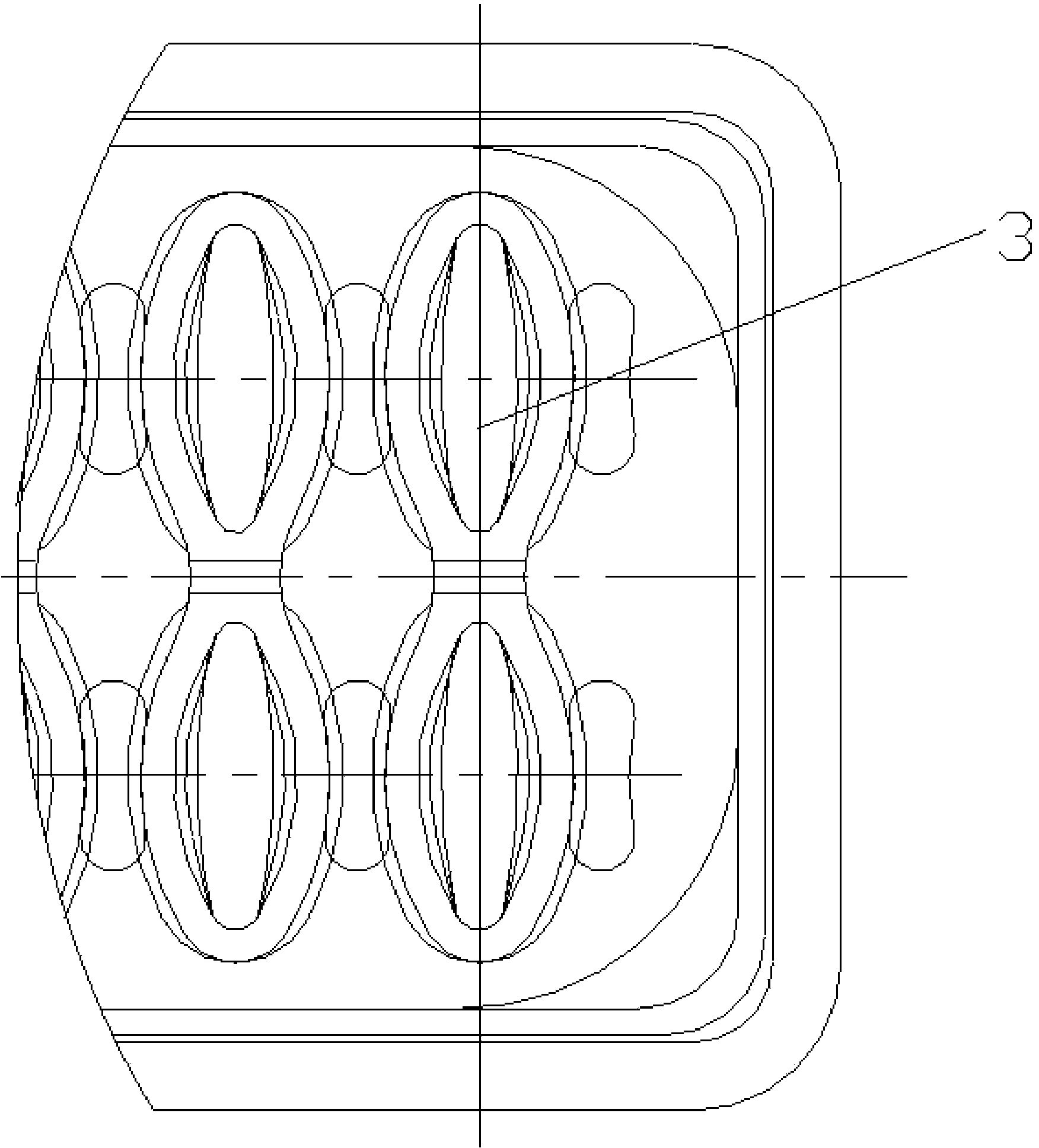

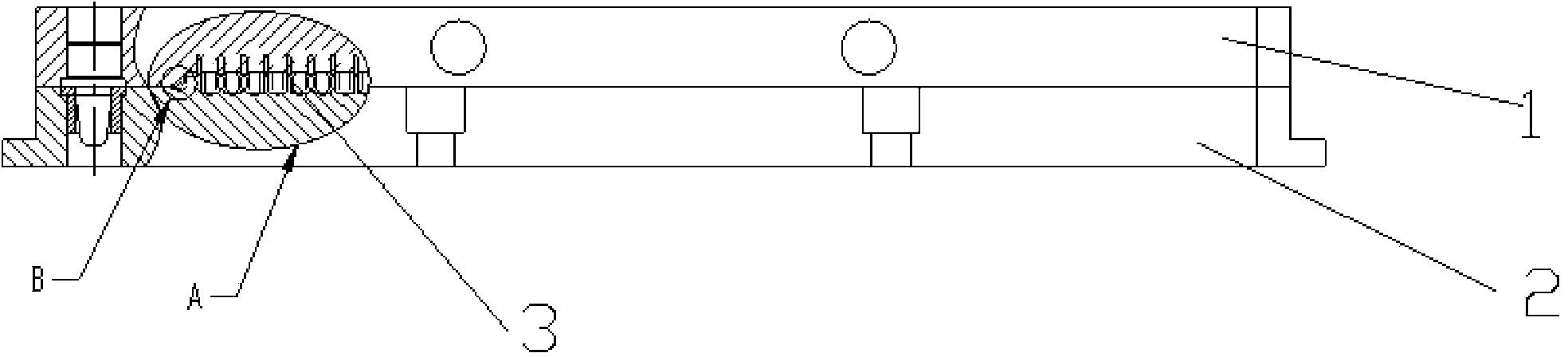

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0035] Figure 1-Figure 5 It is a structural schematic diagram of the sealing strip mold provided by the specific embodiment of the present invention. A sealing strip mold includes a stacked first template 1 and a second template 2 and a plurality of cavities 3 arranged side by side between the first template 1 and the second template 2, formed on the first template 1 and the second template 2 The outside of each cavity 3 between the second templates 2 is provided with an arc-shaped edge tearing groove 4 with a depth between 0.7-0.9mm, which can realize manual edge removal of the mold, and the qualified rate of sealing strip molding is high.

[0036] Specifically, at a distance of 0.15 mm to 0.20 mm from the cavity 3, there is an edge tearing groove 4 for manual edge removal, and a surplus material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com