Automatic control stamping device with bidirectionally-reciprocating platform

A stamping device and reciprocating movement technology, applied in the field of stamping devices, can solve problems such as low efficiency, achieve the effects of improving efficiency, improving work efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

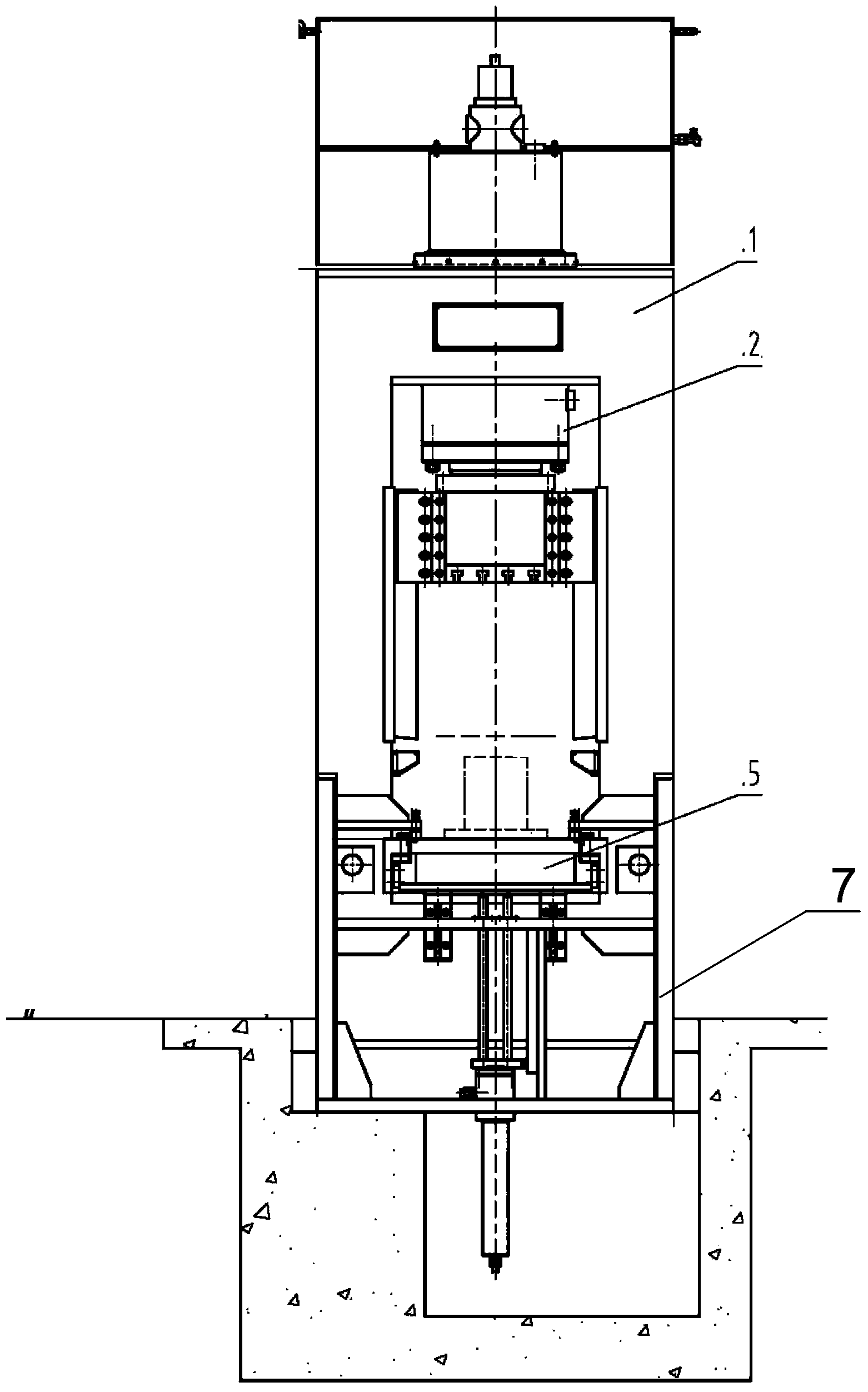

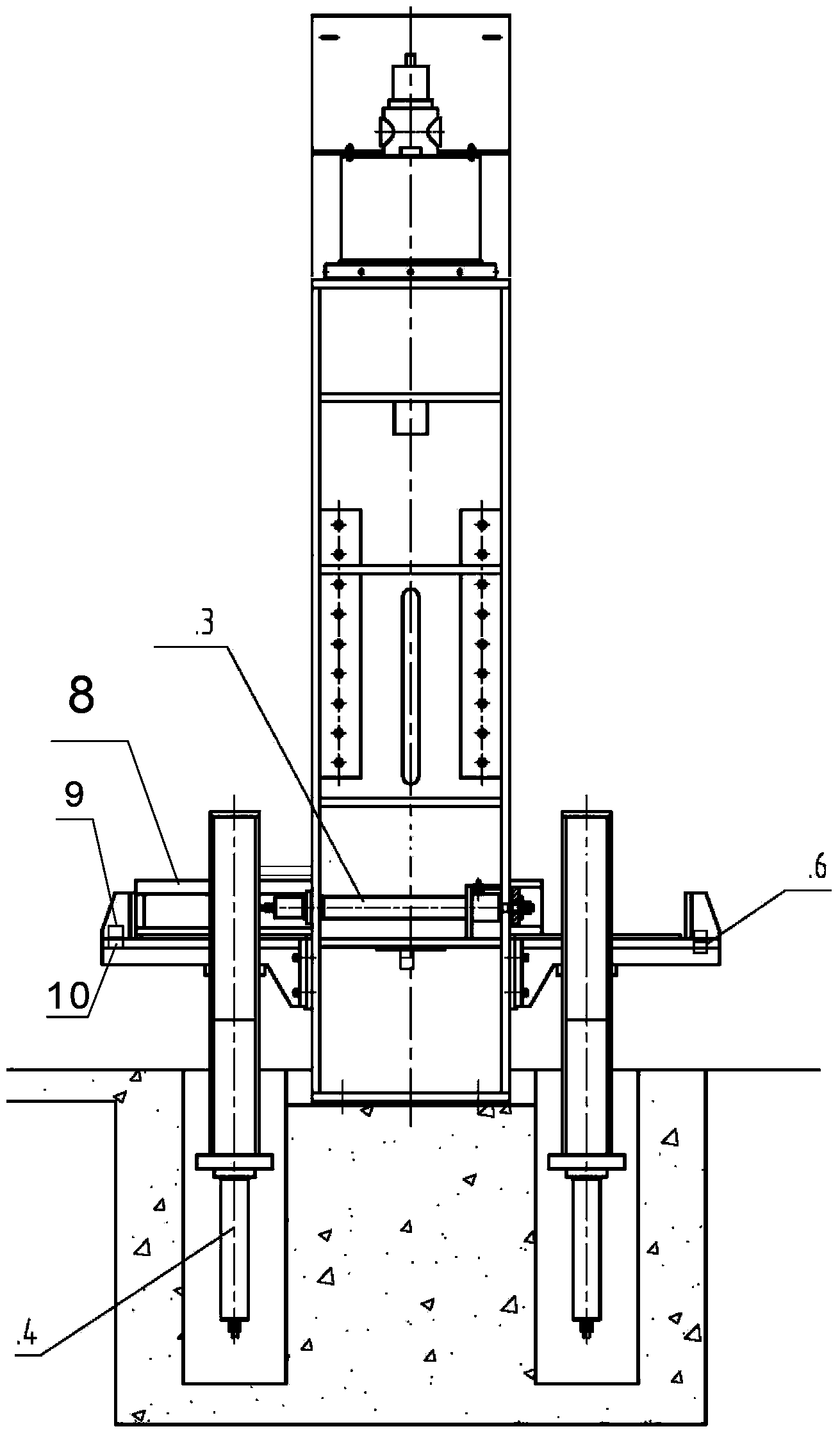

[0013] As shown in the figure, the present invention includes a base 7, a motion platform 5 disposed on the base, a motion guide rail 6 disposed on the motion platform, a stamping die that is set on the motion guide rail and driven by a horizontal moving cylinder to move along the motion guide rail, The frame on the base and the main machine 1 with the stamping cylinder 2 on the top of the frame, the two ends under the base are respectively equipped with ejection mechanisms 4, and the stamping die includes two hollow stamping Die slot 8, touch switch 9 and electromagnetic switch 10 are provided at both ends of the moving guide rail and the extended end of the stamping cylinder.

[0014] The ejecting mechanism includes an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com