Brick conveying truck with removable bottom plate carriage

A technology of movable bottom plate and movable plate, which is applied in the direction of vehicles with swing arms, etc., can solve the problems of inconvenient brick clamps, close contact of brick piles that cannot be loaded, difficult operation of brick clamps, etc., and achieve the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

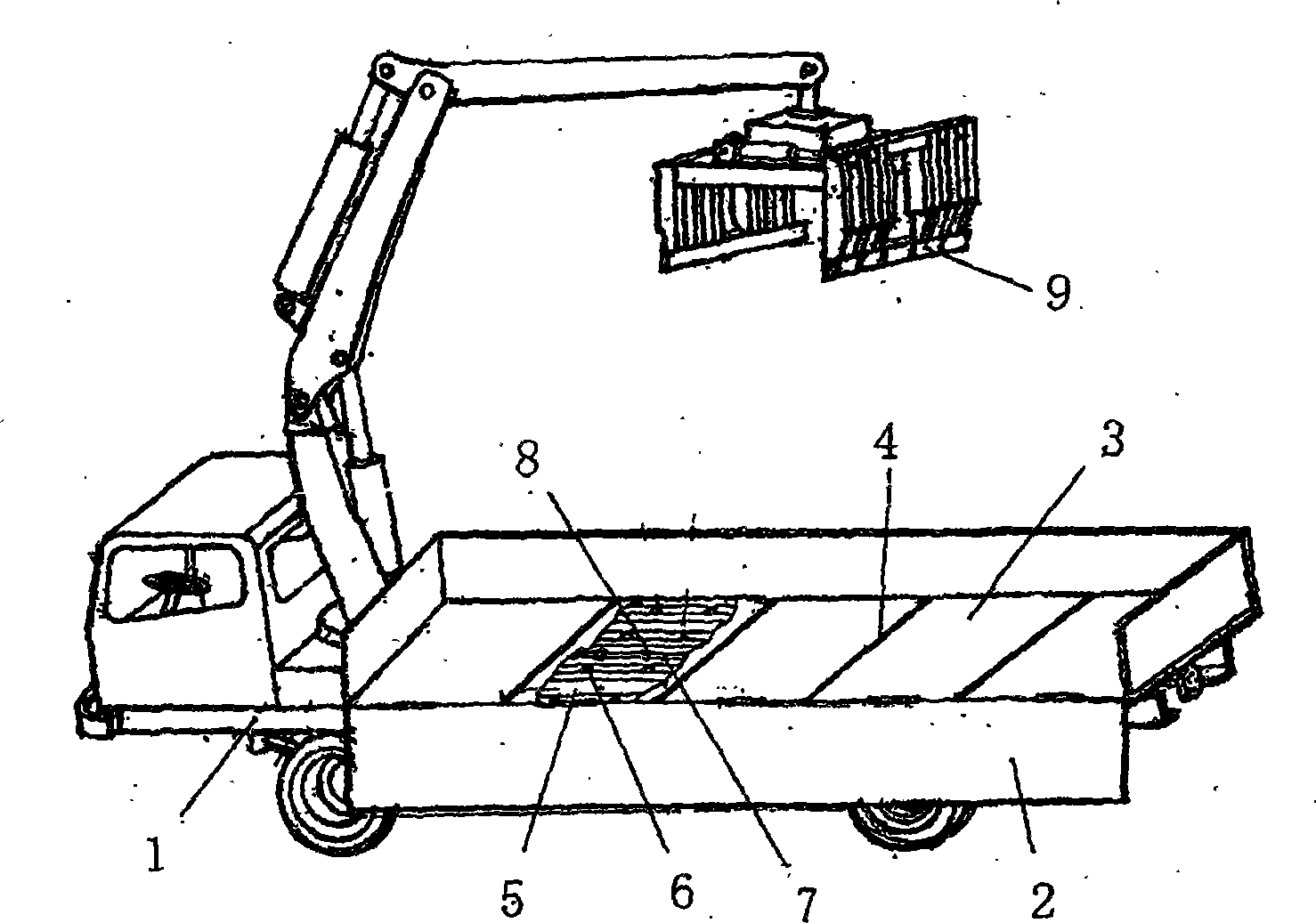

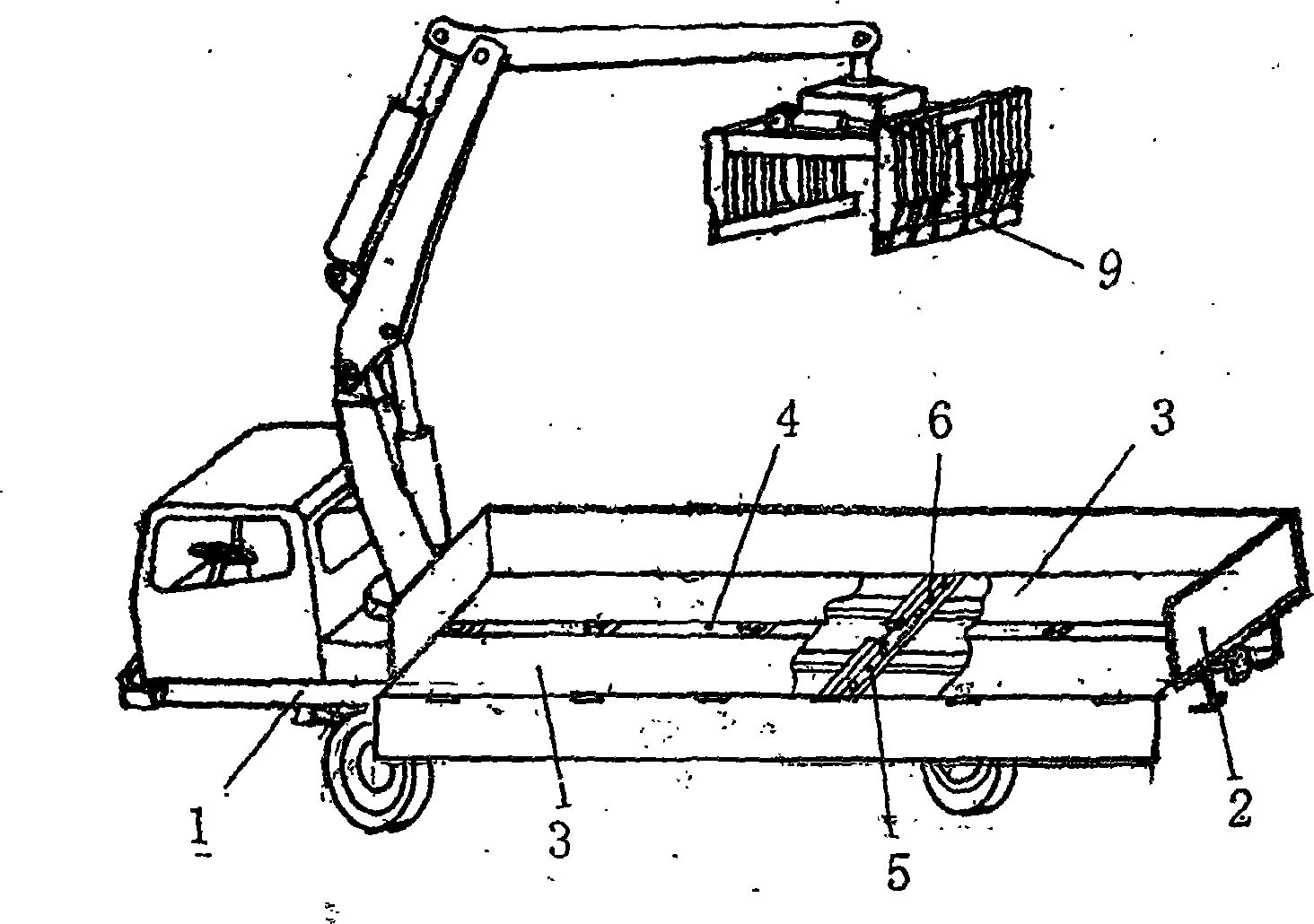

[0014] attached figure 1 , 2 Shown in the embodiment: the loading and unloading brick truck is a car body 1 with a loading and unloading brick clip 9, the bottom plate in the compartment 2 behind the car body 1 is made up of several movable plates 3 that can slide respectively, and each movable plate 3 Leave the adjustable gap 4 that facilitates brick clamp 9 loading and unloading operations between. A plurality of grooved rails 5 are arranged below several movable plates 3 that can slide respectively, and a plurality of pulleys 6 are evenly distributed on several grooved rails 5. Several movable plates 3 are located on the pulleys 6, and the two sides of the movable plate 3 are movable. The movable mode is clamped on the groove rails 5 on both sides. The provided groove rails 5 are arranged laterally, thereby forming a structure in which the movable plate 3 can be adjusted and slid leftward or rightward. The provided groove rails 5 are arranged in a vertical direction to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com