A kind of three-dimensional rare earth coordination polymer green fluorescent material containing mixed carboxylic acid and its preparation method

A coordination polymer, green fluorescence technology, applied in the direction of luminescent materials, compounds containing elements of Group 3/13 of the periodic table, potassium organic compounds, etc., to achieve novel crystal structure, easy large-scale industrial production, low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method comprises the following steps:

[0036] 1) mixing and stirring: Tb(NO 3 ) 3 ·6H 2 O, aminotriacetic acid, oxalic acid and water are mixed with a certain ratio of substances, and then stirred at room temperature for about three hours;

[0037] 2) adjust the pH value: adjust the pH value between 2-6 with the mixture obtained in step 1) with acid and alkali solution;

[0038] 3) Heating: put the mixture obtained in step 2) into a 25ml stainless steel reaction kettle with a polytetrafluoroethylene liner, the filling degree is 80%, seal it, put it into an oven at 120-180°C, under autogenous pressure Under the action, heat and crystallize for 3-6 days. Turn off the power of the oven, gradually cool to room temperature, and open the reaction kettle to obtain colorless and transparent block crystals;

[0039] 4) Washing and drying: the colorless and transparent block crystals obtained in step 3) are washed with distilled water for 1-3 times, and then...

Embodiment 1

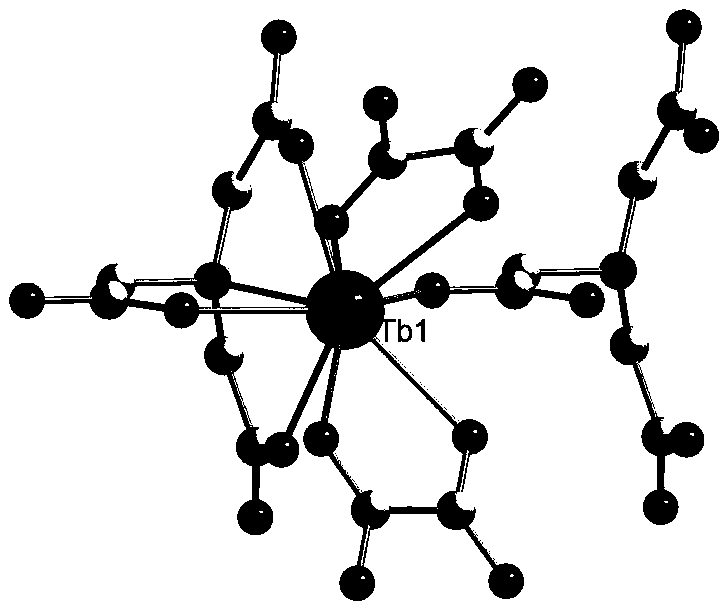

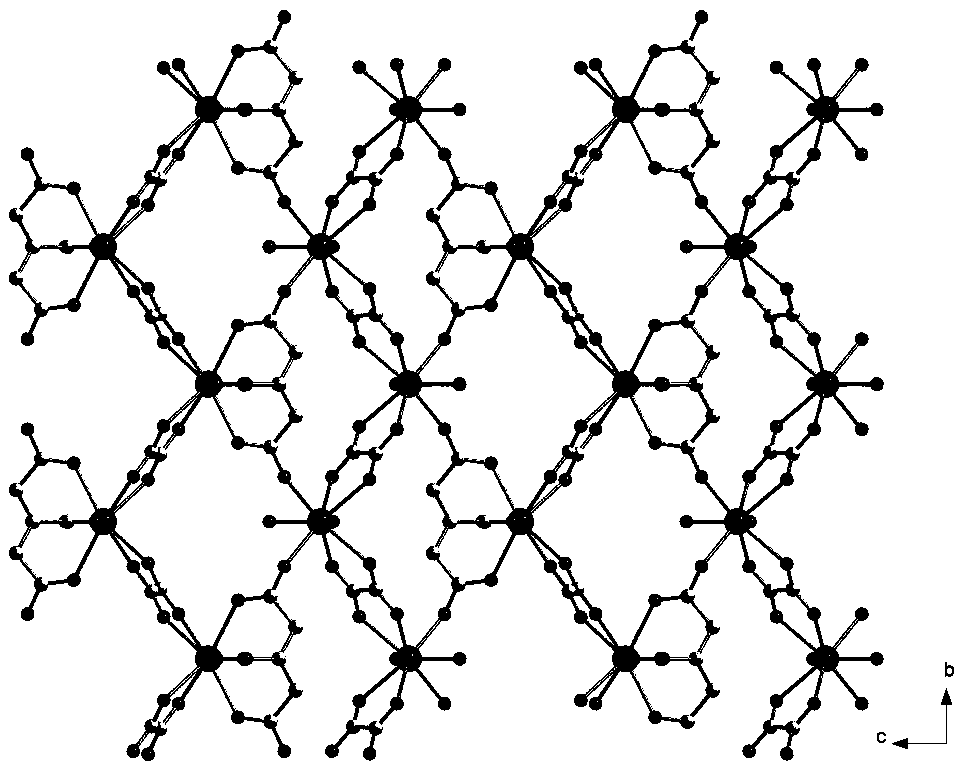

[0045] Preparation method 1 of [KTb2(NTA)(ox)2(H2O)5]n:

[0046] Tb(NO 3 ) 3 ·6H 2 O (0.33g, 0.76mmol), aminotriacetic acid (0.20g, 1mmol), oxalic acid (0.13g, 1mmol) and water (15mL) were mixed in a ratio of 0.76:1:1:833, with 1mol / 1 L of dilute hydrochloric acid and 1 mol / L potassium hydroxide solution to adjust the pH value to 2, then stirred at room temperature for three hours.

[0047] The obtained mixture was put into a 25mL stainless steel reaction kettle lined with polytetrafluoroethylene, with a filling degree of 80%, sealed, placed in an oven at 170°C, and heated for crystallization under autogenous pressure for three days. Turn off the power of the oven, cool down to room temperature gradually, open the reaction kettle to obtain colorless and transparent massive crystals; wash the obtained crystals with distilled water for 3 times, and then dry them for 4 hours at a temperature of 40°C to obtain aminotriacetic acid Three-dimensional terbium coordination polymer...

Embodiment 2

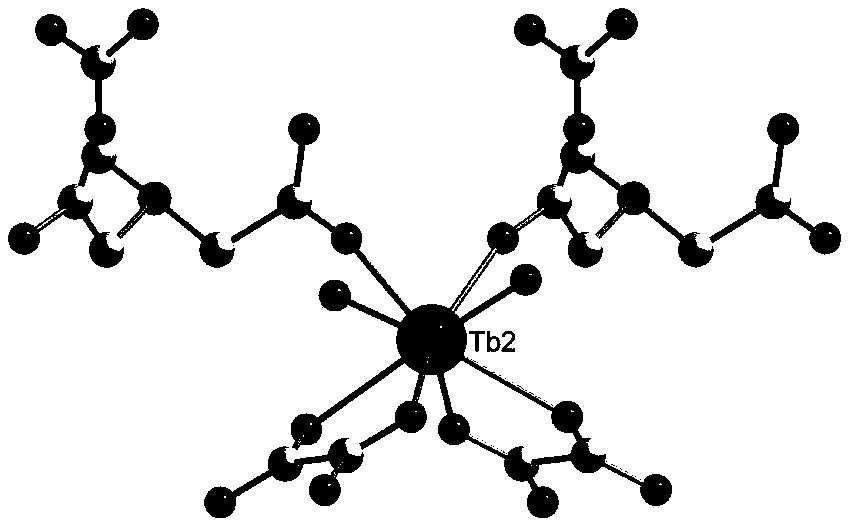

[0054] Preparation method two of [KTb2(NTA)(ox)2(H2O)5]n:

[0055] Tb(NO 3 ) 3 ·6H 2 O (0.33g, 0.76mmol), aminotriacetic acid (0.20g, 1mmol), oxalic acid (0.13g, 1mmol) and water (15mL) were mixed in a ratio of 0.76:1:1:833, with 2mol / 1 L of dilute hydrochloric acid and 2 mol / L potassium hydroxide solution to adjust the pH value to 4, then stirred at room temperature for three hours.

[0056] The obtained mixture was put into a 25mL stainless steel reaction kettle lined with polytetrafluoroethylene, with a filling degree of 80%, sealed, placed in an oven at 160°C, and heated for crystallization under autogenous pressure for 5 days. Turn off the power of the oven, cool down to room temperature gradually, and open the reaction kettle to obtain colorless and transparent massive crystals; wash the obtained crystals with distilled water for 3 times, and then dry them at 70°C for 3 hours to obtain aminotriacetic acid Three-dimensional terbium coordination polymer green fluoresc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com