Processing cartridge

A process cartridge and electronic imaging technology, applied in the field of process cartridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

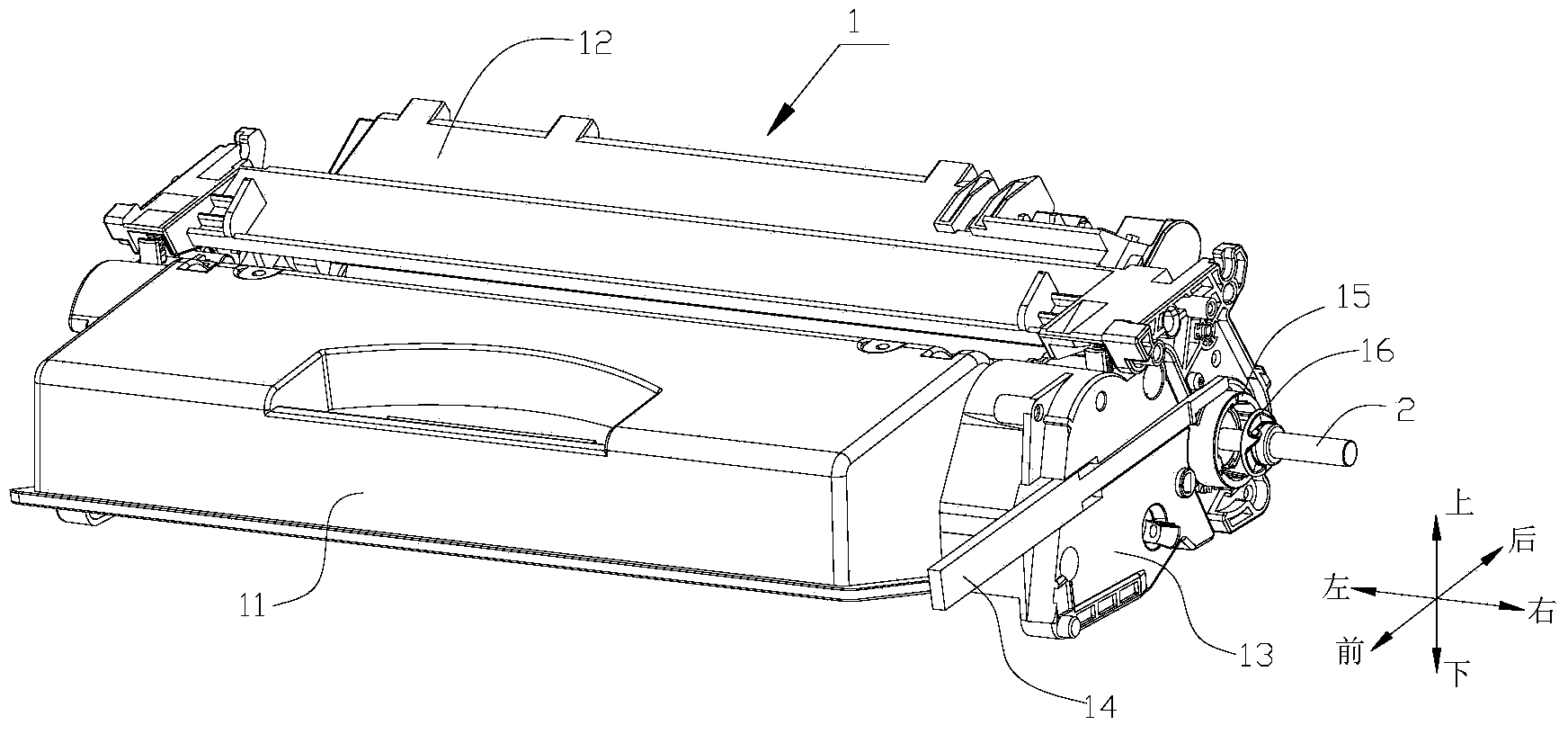

[0031] figure 1 It is a perspective view of a process cartridge using a positioning ring scheme in the prior art, 1 is a process cartridge, including a process cartridge housing, and the process cartridge housing includes a developer accommodating part 11 for accommodating developer and a part 12 for accommodating waste developer.

[0032] On the developer accommodating portion 11 is placed a developing roller or magnet roller (not shown in the figure) for transferring the developer. A photosensitive element (such as figure 2 Shown photosensitive element 17), and a charging element (not shown) for charging the photosensitive element.

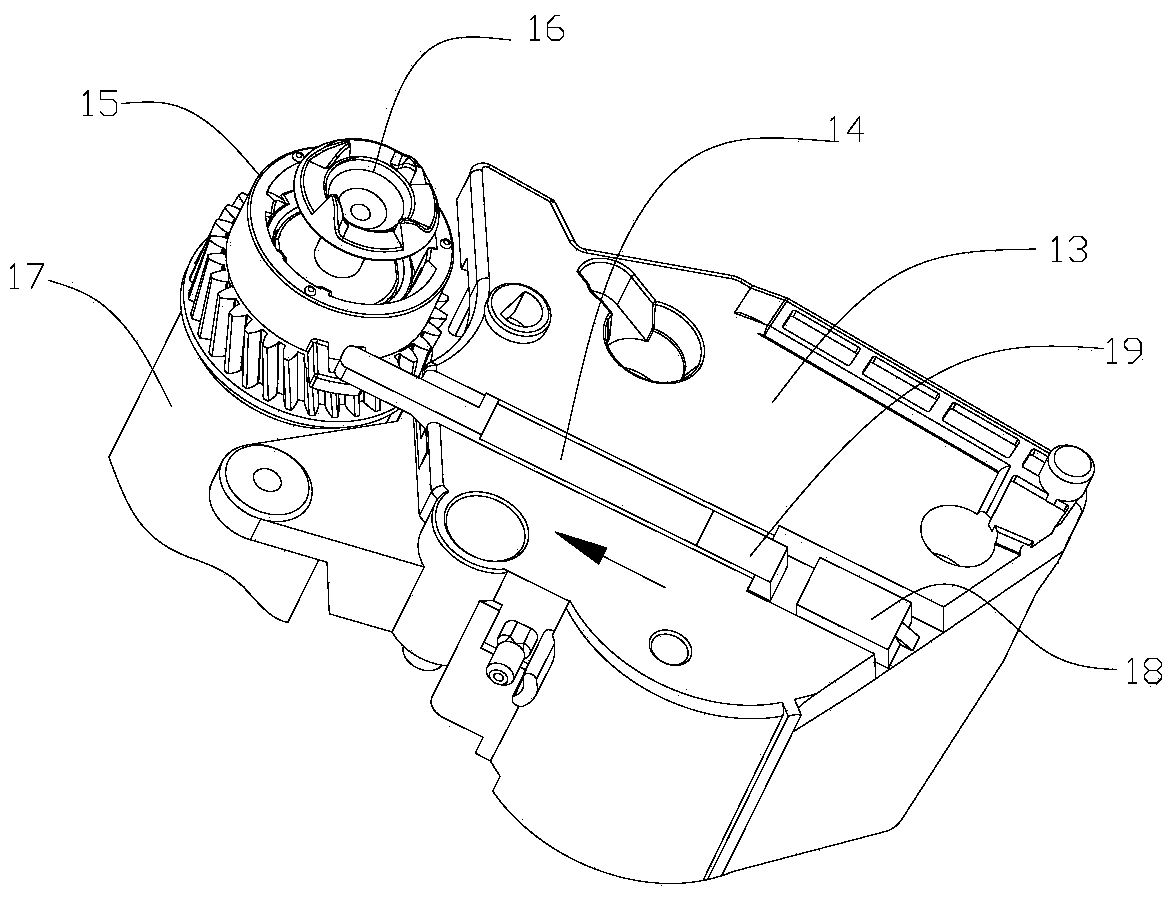

[0033] One end in the axial direction of the photosensitive element 17 is provided with a rotational power receiving head 16 that engages with the rotational force driving head 2 provided in the electronic imaging device to receive power, and assists the positioning of the rotational power receiving head 16 in the axial direction of the photos...

Embodiment 2

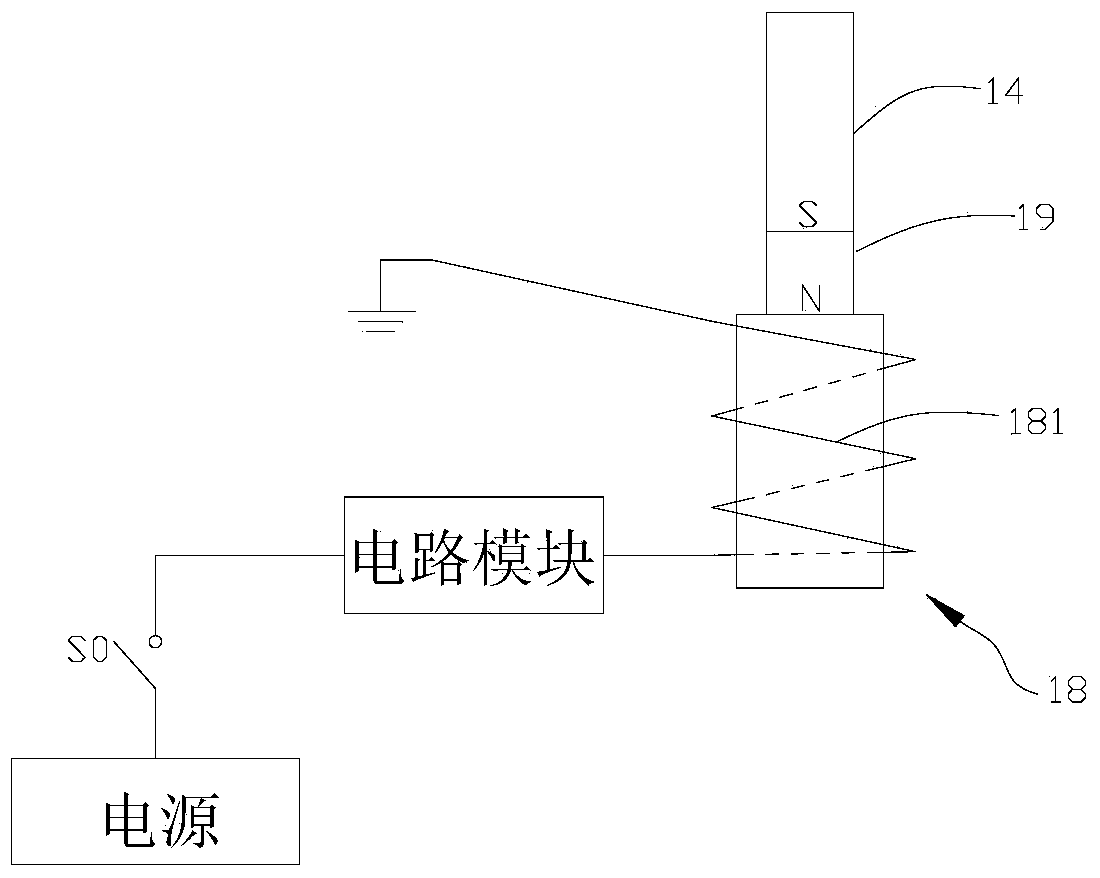

[0046] In the first embodiment, the extension of the pressing rod 14 is controlled by the electromagnet, so that the positioning ring 15 rotates, and drives the rotation power receiving head 16 to protrude along the axis of the photosensitive element and meshes with the rotation force driving head 2 to transmit power. However, in this implementation, the pressing rod can be attracted after the electromagnet is energized, and the rotating power receiving head is urged to protrude along the axis direction of the photosensitive element after the positioning ring is also rotated. The mechanism connected with the rotary power receiving head does not need to be changed, only the pressing rod 14 needs to be placed in a position symmetrical to the axis of the photosensitive element with respect to the position of the pressing rod in Embodiment 1, as Image 6 shown.

[0047] In this embodiment, the permanent magnet 19 provided at the end of the pressing rod in the embodiment is replace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com