Connection terminals, sealed connection terminals and connectors

A technology for connecting terminals and connectors, which is applied in the direction of connection, parts and contact parts of connecting devices, etc., can solve the problem that the connecting terminal 1 is difficult to insert into the accommodating hole, the O-ring is squeezed, and the sealing effect cannot be achieved, etc. problem, to achieve the effect of simple structure, ensuring sealing effect and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

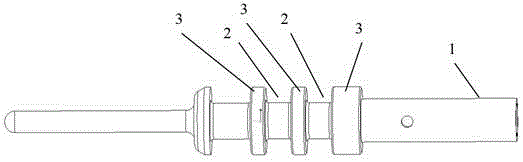

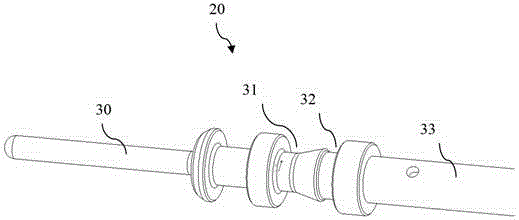

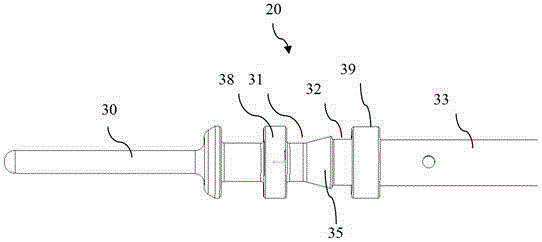

[0064] Such as figure 2 , 3 As shown in and 4, the connection terminal 20 includes a terminal body 30 for electrical connection with a mated terminal. The terminal body 30 is a cylinder. The terminal body 30 is provided with first accommodating grooves 31 and second accommodating grooves 32 distributed along the length direction. The connection terminal 20 also includes a wiring body 33 for connecting a wire end (not shown in the figure). in such as Figure 4 In the example shown, the terminal body 33 is provided with an axial cavity 33a for receiving a wire end.

[0065] Such as figure 2 , image 3 and Figure 4 As shown in , both the first accommodating groove 31 and the second accommodating groove 32 are arranged for one circle along the circumferential direction of the terminal body 30 . From image 3 In the front view direction of the connecting terminal shown, the first accommodating groove 31 and the second accommodating groove 32 can extend from the surface ...

Embodiment 2

[0069] Such as Figure 5A , Figure 5B and Figure 6 As shown, the sealed connection terminal 40 includes the connection terminal 20 and a sealing ring 50 . The sealing ring 50 is sleeved on the connecting terminal 20 .

[0070] Such as figure 2 , image 3 and Figure 4 As shown, the connection terminal 20 includes a terminal body 30 . The terminal body 30 is a cylinder. The terminal body 30 is provided with first accommodating grooves 31 and second accommodating grooves 32 distributed along the length direction. The connection terminal 20 also includes a wiring body 33 for connecting a wire end (not shown in the figure).

[0071] Both the first accommodating groove 31 and the second accommodating groove 32 are arranged for one circle along the circumferential direction of the terminal body 30 . The first accommodating groove 31 and the second accommodating groove 32 can either extend from the surface of the terminal body 30 to the axial direction and be lower than t...

Embodiment 3

[0077] Such as Figure 7 , Figure 8 and Figure 9 As shown, the connector 60 includes a housing 70 and a sealed connection terminal 40 . The casing 70 is provided with a receiving hole 71 . The sealed connection terminal 40 is inserted into the accommodation hole 71 .

[0078] The sealed connection terminal 40 includes the connection terminal 20 and a sealing ring 50 . The sealing ring 50 is sleeved on the connecting terminal 20 .

[0079] Such as figure 2 , image 3 and Figure 4 As shown, the connecting terminal 20 includes a terminal body 30 . The terminal body 30 is a cylinder. The terminal body 30 is provided with first accommodating grooves 31 and second accommodating grooves 32 distributed along the length direction. Both the first accommodating groove 31 and the second accommodating groove 32 are arranged for one circle along the circumferential direction of the terminal body 30 . The first accommodating groove 31 and the second accommodating groove 32 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com