Housing wall screw connection for an electrical connector

A technology of electrical devices and plugs, which is applied to parts, connections, electrical components, etc. of connecting devices, and can solve problems such as tolerances and installation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

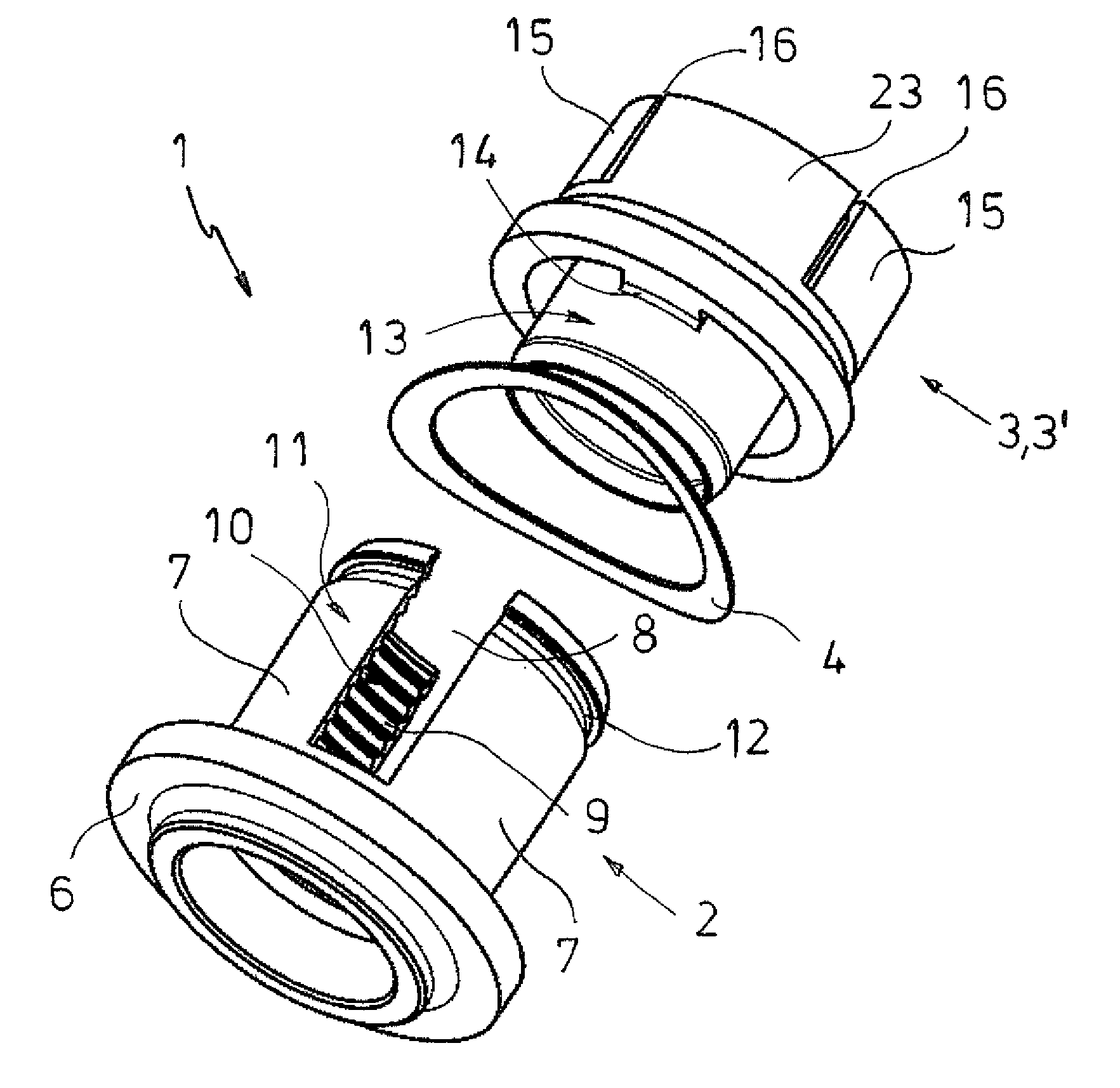

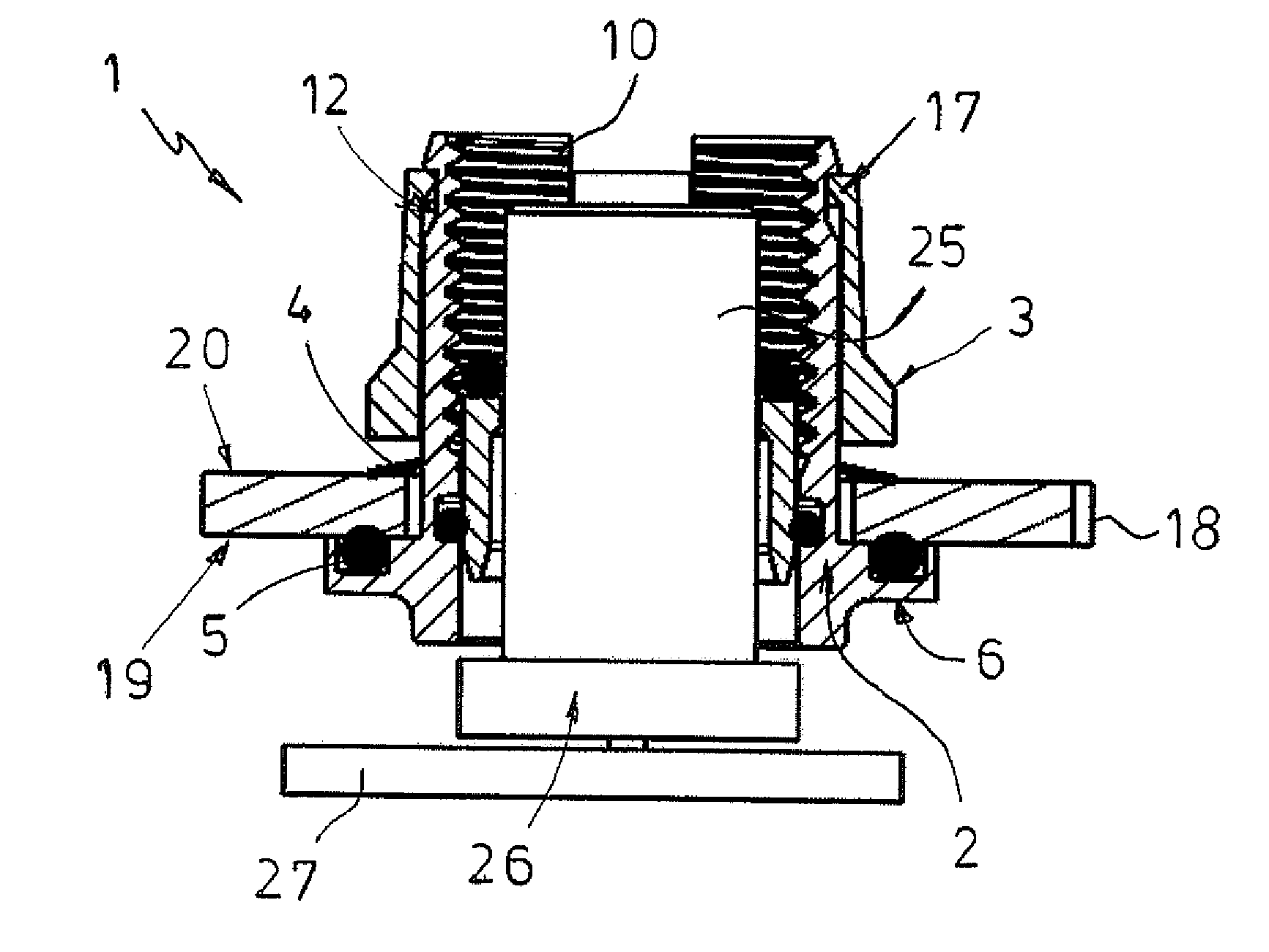

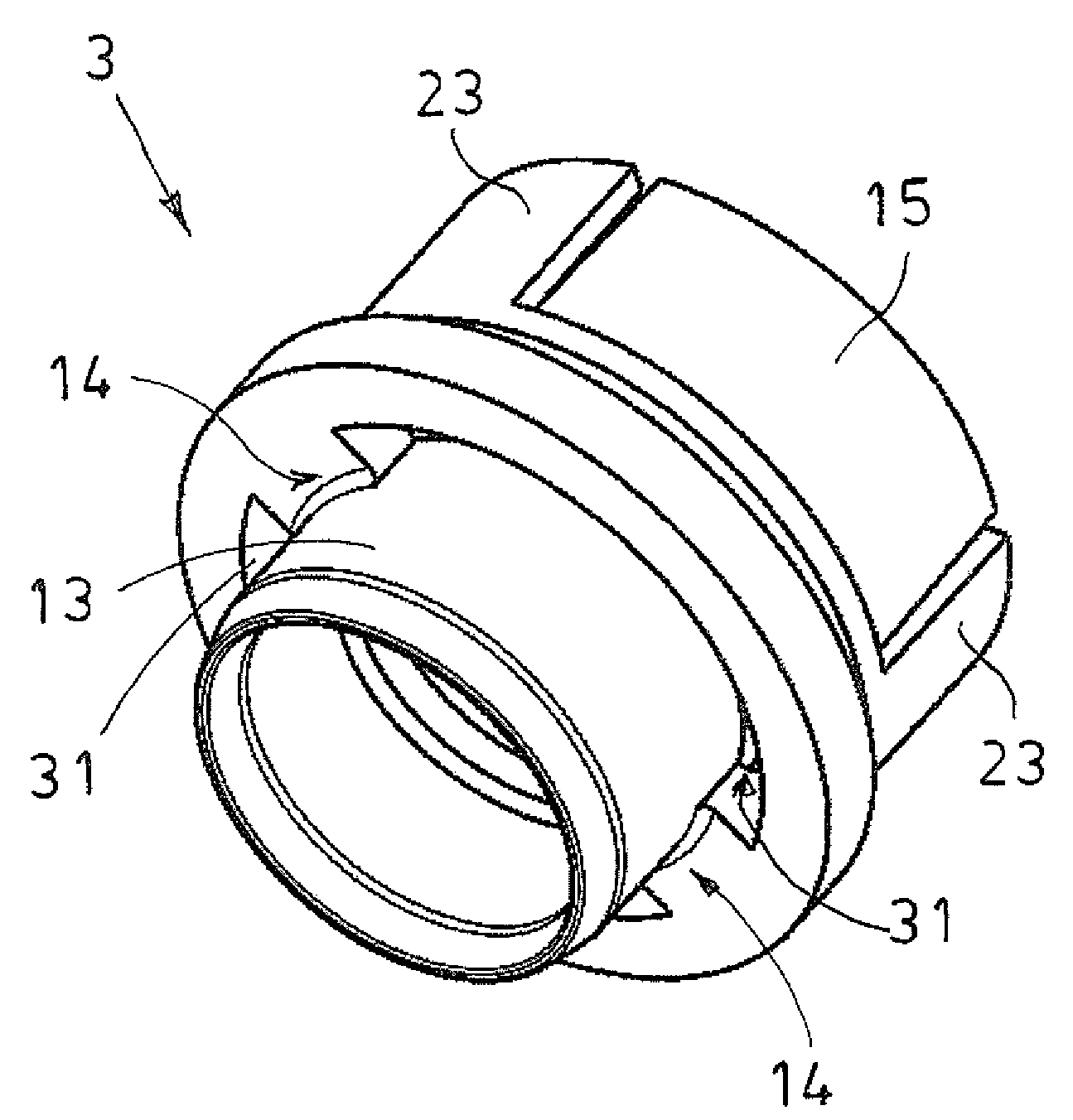

[0024] Figure 1a shows an example of an embodiment of a sealing wall grommet 1 according to the invention comprising a flange-shaped mounting sleeve 2, a tubular tensioning sleeve 3 as tensioning element 3', a flexible tensioning ring 4 and an elastic Ring seal 5. Figure 1a shows a side view of the wall grommet 1 in assembled form, Figure 1b An exploded perspective view showing the wall grommet. exist Figure 1a Seals visible in 5 in Figure 1b is concealed behind a pedestal 6 which is connected to the mounting sleeve 2 and extends around its outer circumference. The mounting sleeve 2 has two sleeve segments 7 which extend in the axial direction and which are separated by a gap 8 between the two segments. On the inner wall 9 of the mounting sleeve 2, the sleeve segments 7 have an internal thread 10, and on the outer wall 11 they have matching locking means 12 for the tensioning sleeve 3, which are locked Designed as a circumferential annular groove. The tensioning sleev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap