Damper housing structure body and damper housing structure body fabrication method

A manufacturing method and shock absorber technology, applied in the direction of upper structure, manufacturing tools, upper structure sub-assembly, etc., can solve problems such as inability to weld joints, difficult joint strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

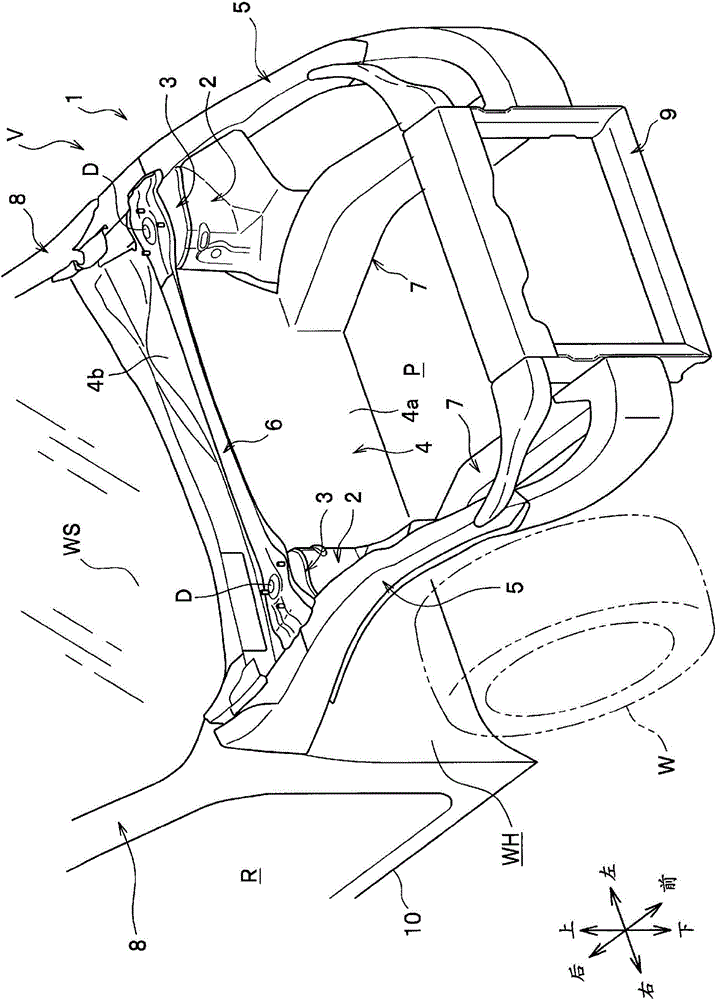

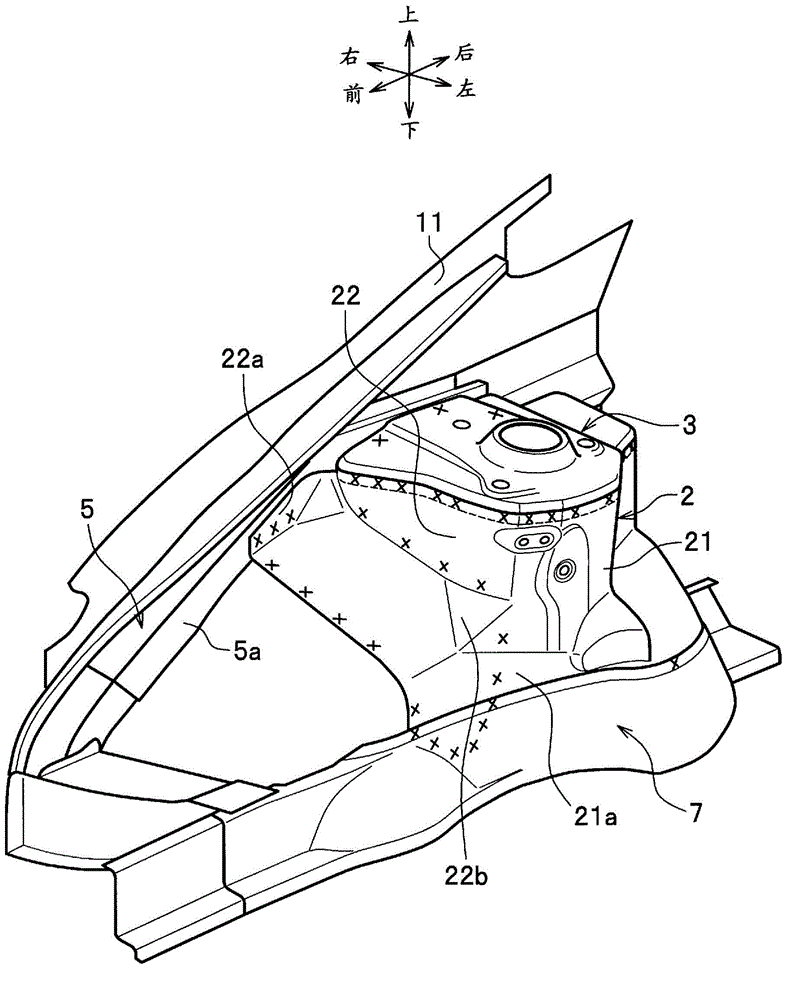

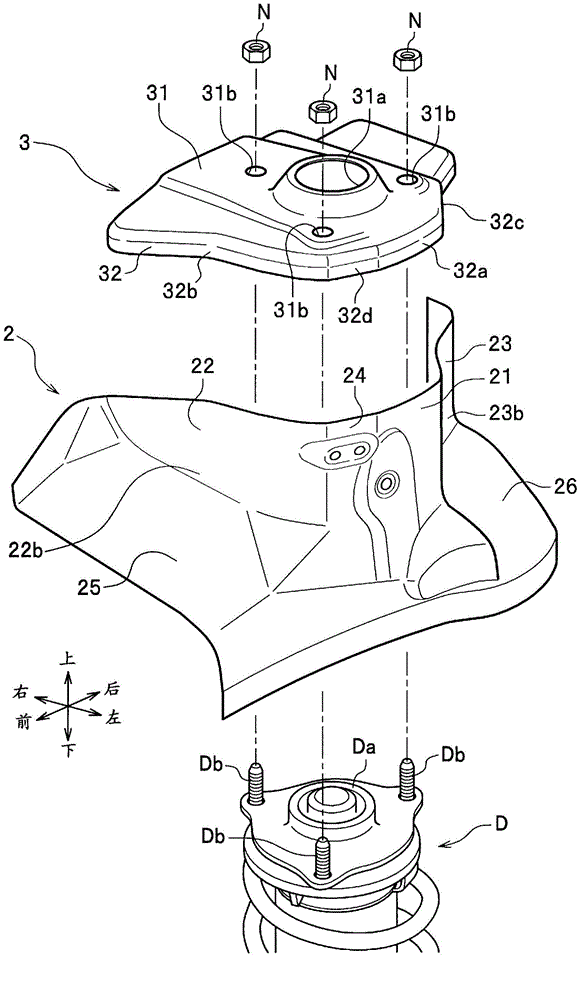

[0033] Regarding the embodiment of the present invention, taking the case of applying the shock absorber housing structure of the present invention to the vehicle front structure as an example, refer to Figure 1 to Figure 5 Describe in detail. In the description, the same reference numerals are assigned to the same elements, and overlapping descriptions are omitted. In addition, when describing a direction, it demonstrates based on front-back, left-right, up-and-down seen from the driver of a vehicle. In addition, the vehicle width direction is synonymous with the left-right direction.

[0034] figure 1 It is a perspective view of a vehicle front structure of a vehicle having the damper housing structure according to the present embodiment, viewed obliquely from the front right. Such as figure 1 As shown, the vehicle V is a so-called automobile, and includes: a power room P that accommodates a power unit such as an engine; a vehicle compartment R that serves as a passenge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com