Filling machine and filling head

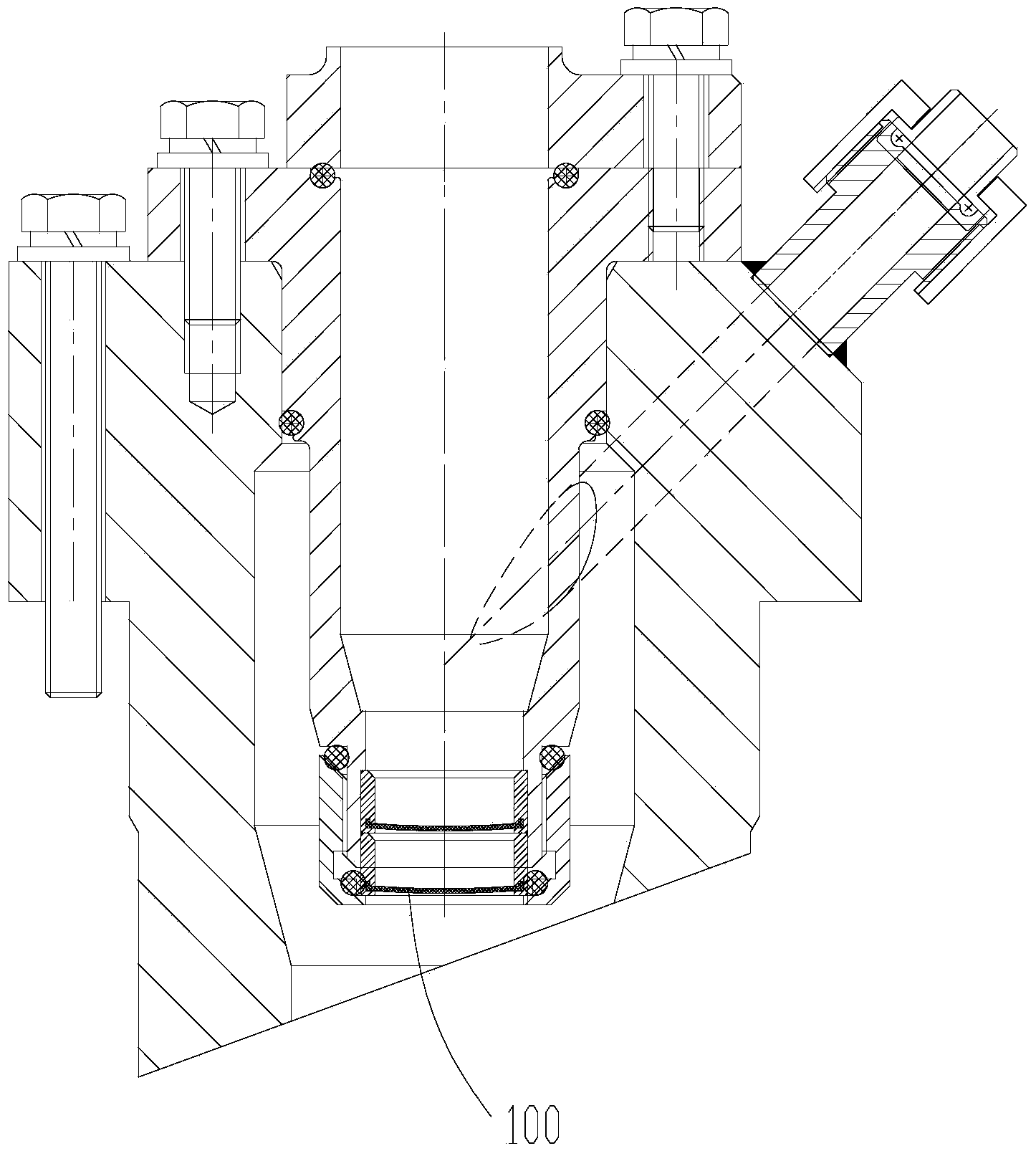

A filling head and filling machine technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of easy clogging of the filter screen 100, failure of filling, complex structure, etc., and achieve low cost and simple structure , The effect of smooth filling channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

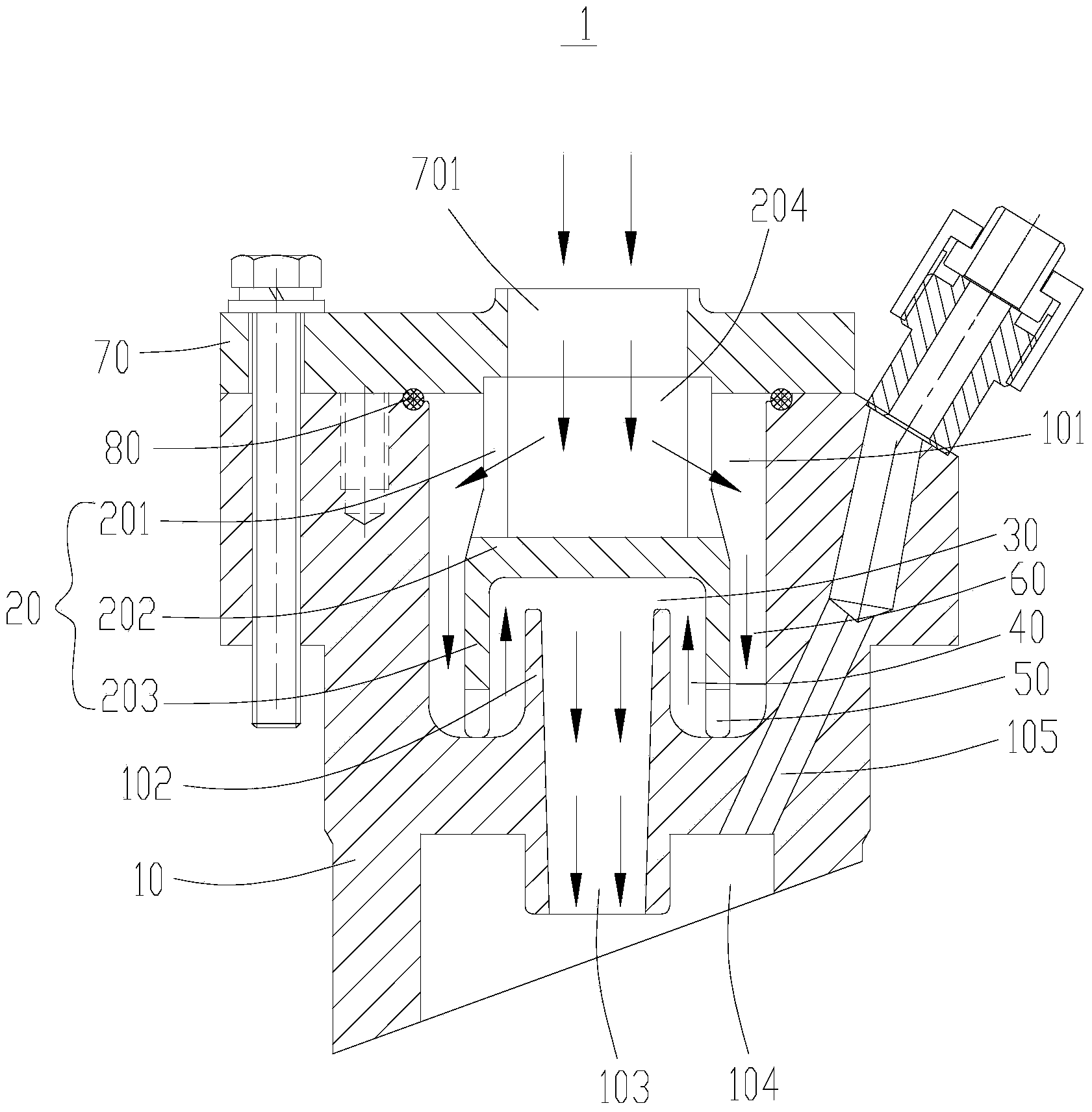

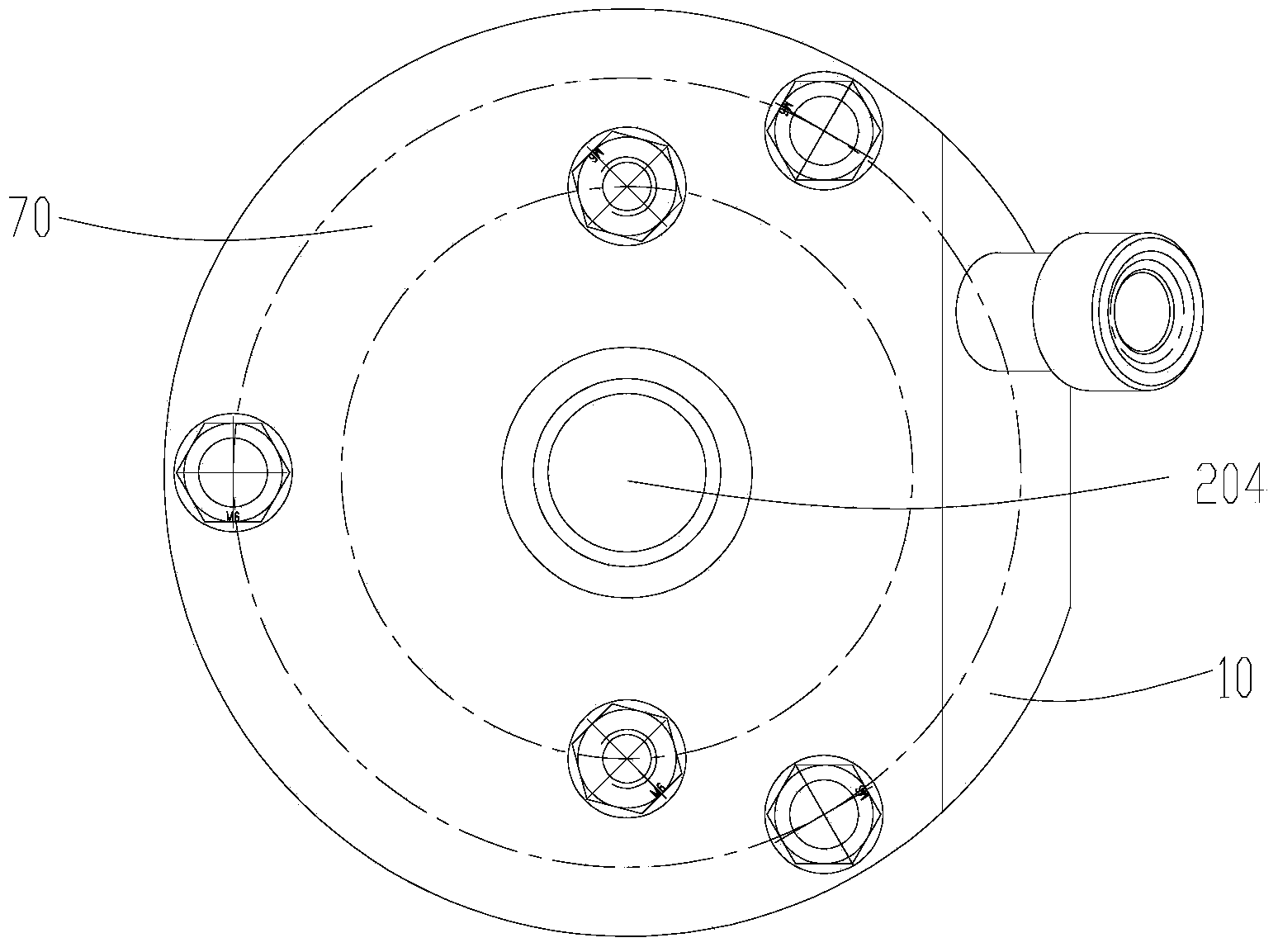

[0024] Such as figure 2 , image 3 As shown, a filling head 1 includes a hollow valve head body 10, the upper end of the valve head body is provided with an opening communicating with the inner cavity 101 of the valve head body, and the lower end inner wall of the valve head body is provided with An upward projection 102 is provided with an outlet 103 communicating with the internal cavity 101, and the internal cavity 101 is provided with a block 20, and the block 20 includes a connecting portion 201 connected in sequence, a first Blocking portion 202, second blocking portion 203, the connecting portion 201 is connected to the upper end of the valve head body, and the connecting portion 201 is provided with an inlet 204 matching the opening, the first blocking portion 202 is arranged on the Above the protrusion 102 , the second shielding portion 203 is disposed on a side of the protrusion 102 .

[0025] The filling head 1 described in this embodiment, by setting the block 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com