360-degree mould frame

A mold frame and connecting rod technology, used in textiles and papermaking, hand sewing tools, cloth feeding mechanisms, etc., can solve the problems of mold non-reusability, inability to complete, low operation efficiency, etc., and reduce labor costs and product costs. , The effect of low technical requirements and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

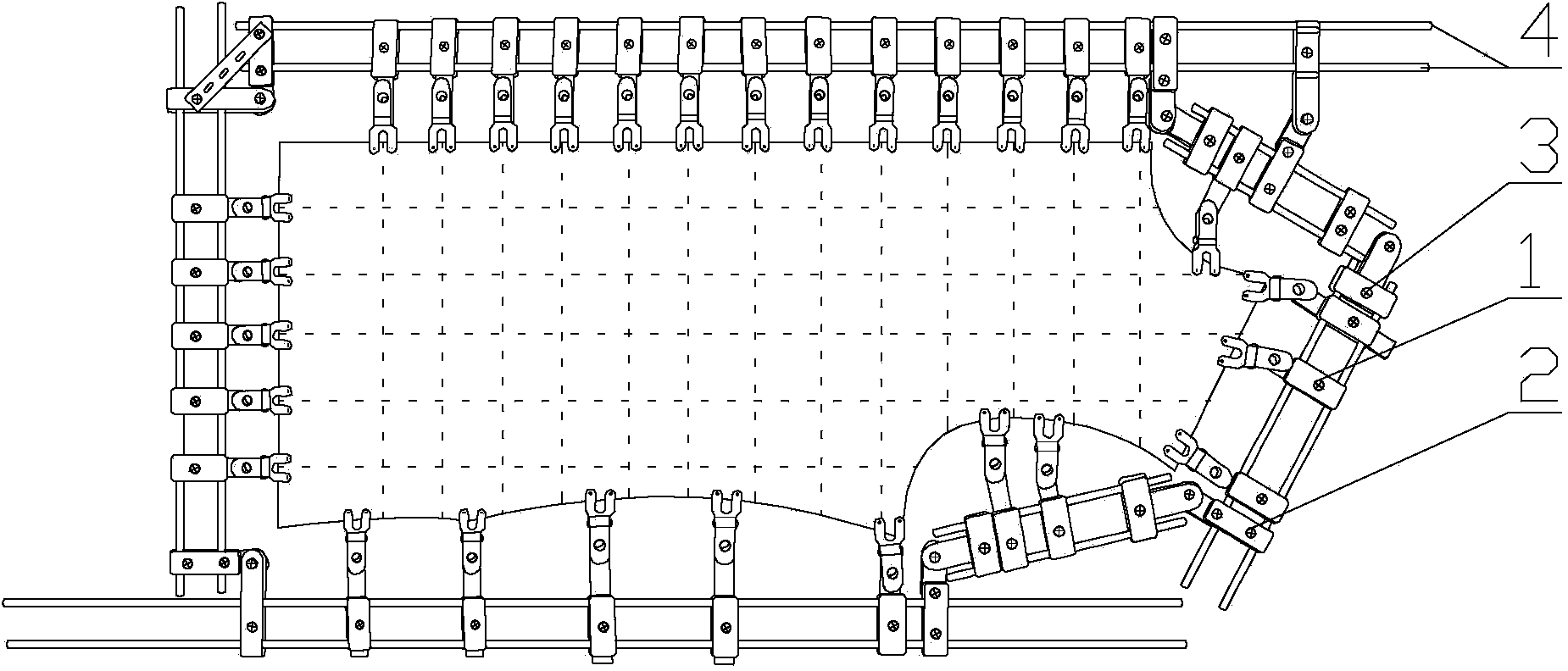

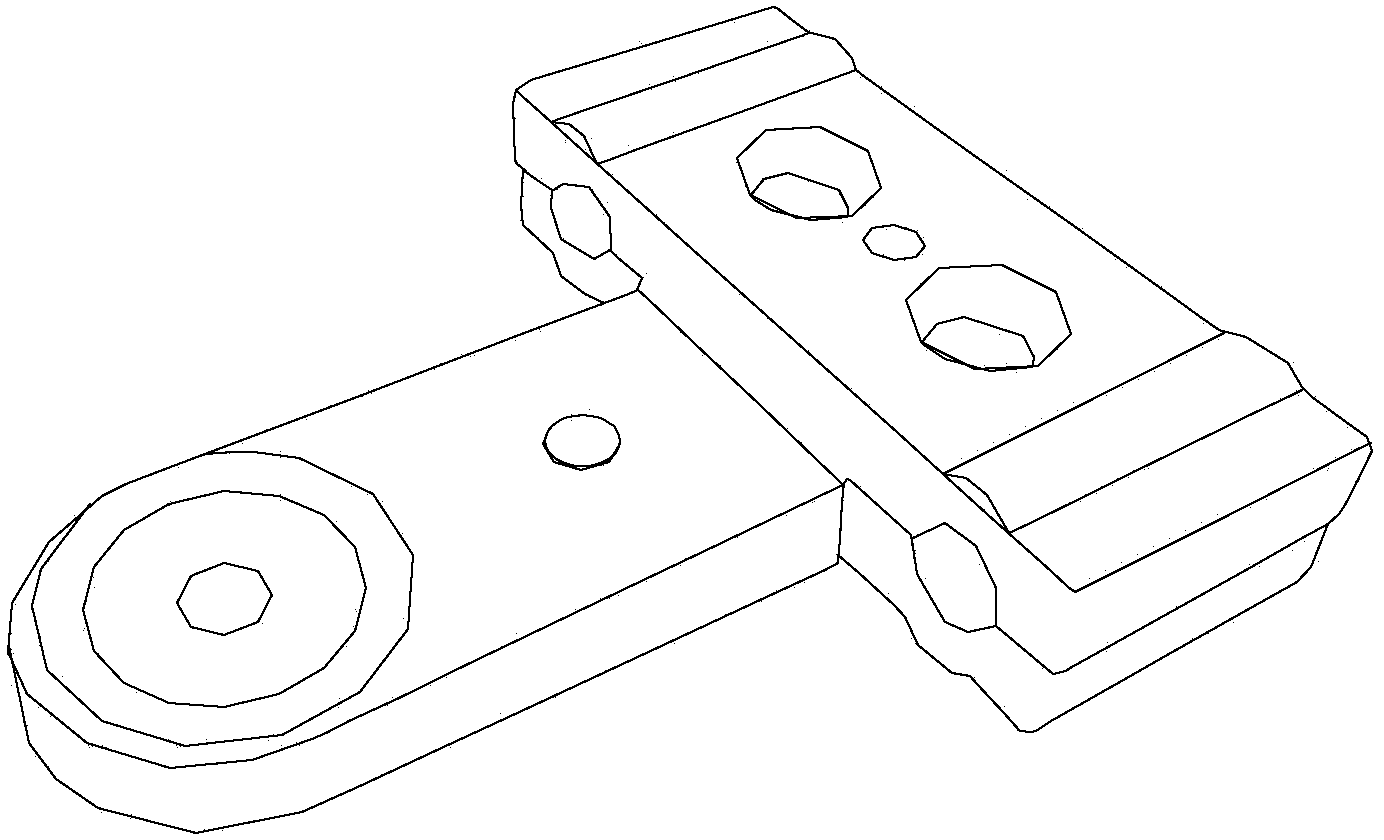

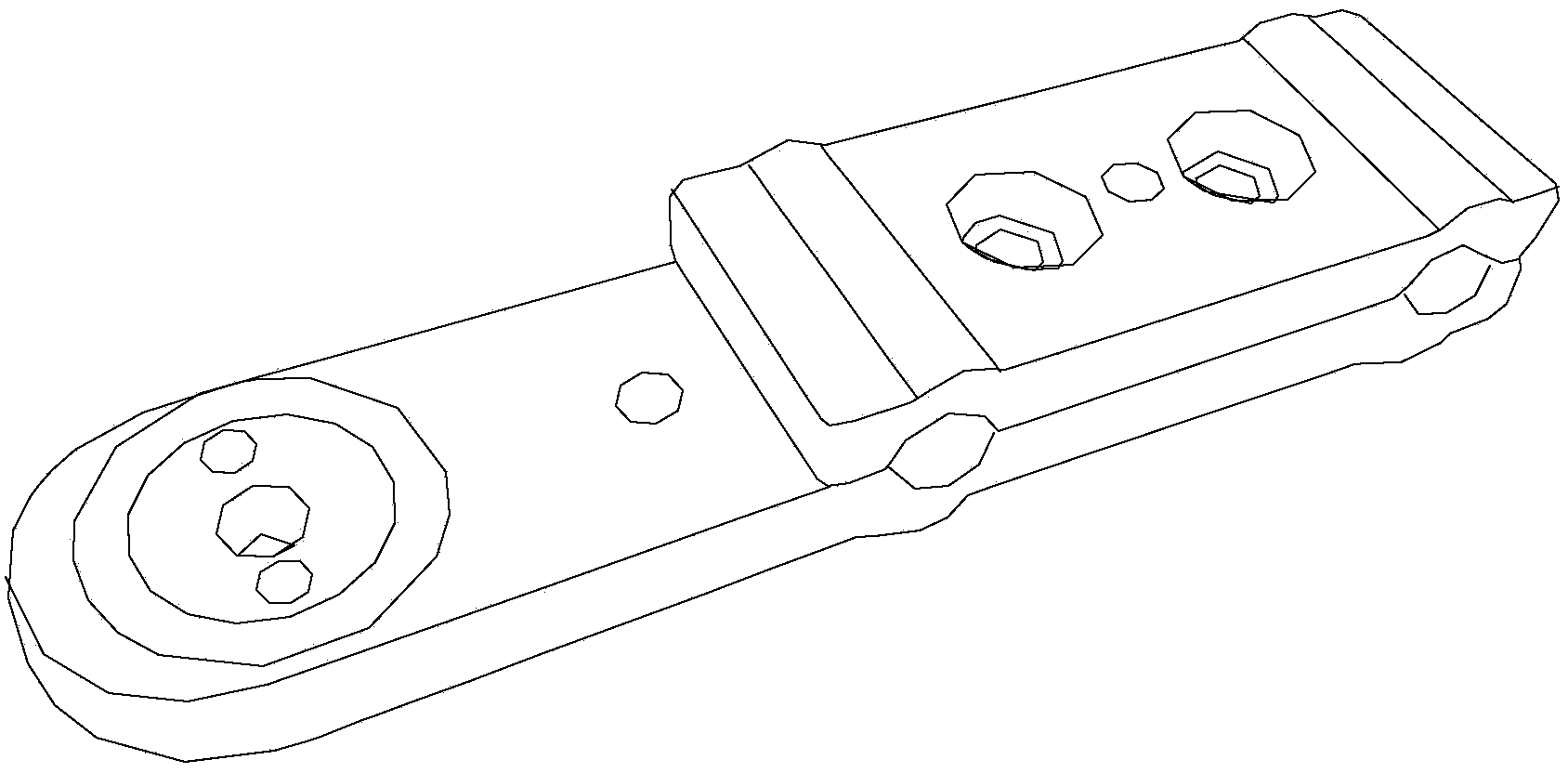

[0016] see Figure 1-4 , in an embodiment of the present invention, a 360 mold frame includes a clamp 1 with a thimble, a vertical fixture 2, a curved fixture 3 and a connecting rod 4, and one end of the clamp 1 with a thimble is provided with two through Holes for connecting two parallel connecting rods 4, the other end of the clamp 1 with a thimble is perpendicular to the connecting rod 4, and one end of the vertical fixing member 2 is provided with two through holes for connecting two Parallel connecting rods 4, the other end of the vertical fixing member 2 is perpendicular to the connecting rod 4, and one end of the curved fixing member 3 is provided with two through holes for connecting two parallel connecting rods 4, the curved The other end of the fixing member 3 is parallel to the connecting rod 4, and the other end of the curved fixing rod 3 is connected to the other end of the vertical fixing member 2 for changing the angle between the connecting rods 4, and the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com