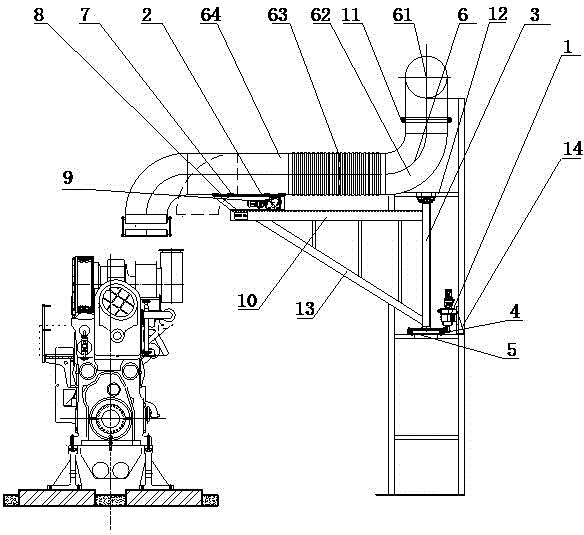

Engine test bed exhaust system

An exhaust system and test bench technology, which is applied in engine testing, machine/structural component testing, measuring devices, etc., can solve problems such as low efficiency and inaccurate test results, and achieve the effect of fast docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0012] like figure 1 As shown, the engine test bench exhaust system of the present invention includes a swing reduction motor 1, a telescopic reduction motor 2 and an exhaust swing pipe 6, the swing reduction motor 1 is fixed on the bracket 14, and the swing reduction motor 1 output shaft There is a small gear 4 on the end sleeve, and the pinion gear 4 meshes with the large gear 5 in the horizontal direction. The large gear 5 is set on the swing tube shaft 3, and the swing platform 12 is installed on the top of the swing tube shaft 3. The exhaust swing tube 6 includes exhaust pipes connected in sequence. Fixed pipe 61, curved pipe section 62, telescopic hose 63 and telescopic section hard pipe 64, telescopic deceleration motor 2 is installed under telescopic section hard pipe 64, and telescopic section hard pipe 64 is equipped with linear guide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap