Paving device for sidewalk floor tiles for road construction

A technology for laying devices and sidewalks, which is applied to roads, roads, pavements paved with prefabricated blocks, etc., and can solve problems such as time-consuming, time-consuming and labor-intensive, and disorderly brick materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

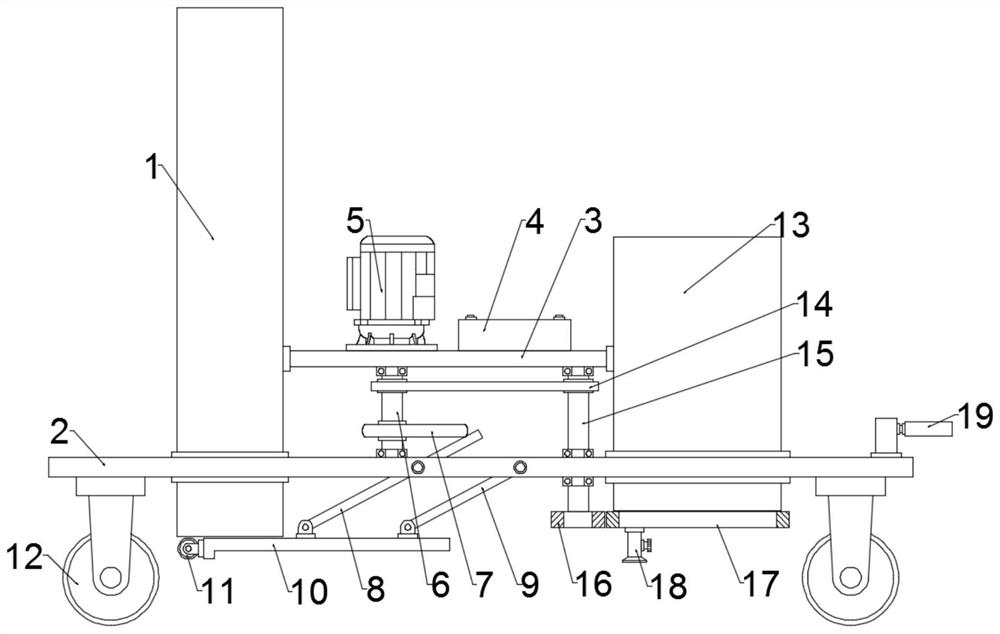

[0021] see Figure 1~3 , in an embodiment of the present invention, a sidewalk floor tile laying device for road construction, comprising a brick box 1, a car board 2 for fixing the brick box 1, moving wheels 12 installed at the four corners below the car board 2, and a Swing assembly; specifically, the brick box 1 runs through the car plate 2, the side wall of the brick box 1 is fixed with a beam 3, and the flange of the beam 3 is fixed with a drive motor 5 connected to a power supply and a switch with a wire, and the drive motor 5 outputs The end is connected to the output shaft 6, the bearing at the lower end of the output shaft 6 is connected to the car plate 2, and the switch is turned on to make the drive motor 5 energized to drive the output shaft 6 to rotate; the output shaft 6 is connected to the swing assembly;

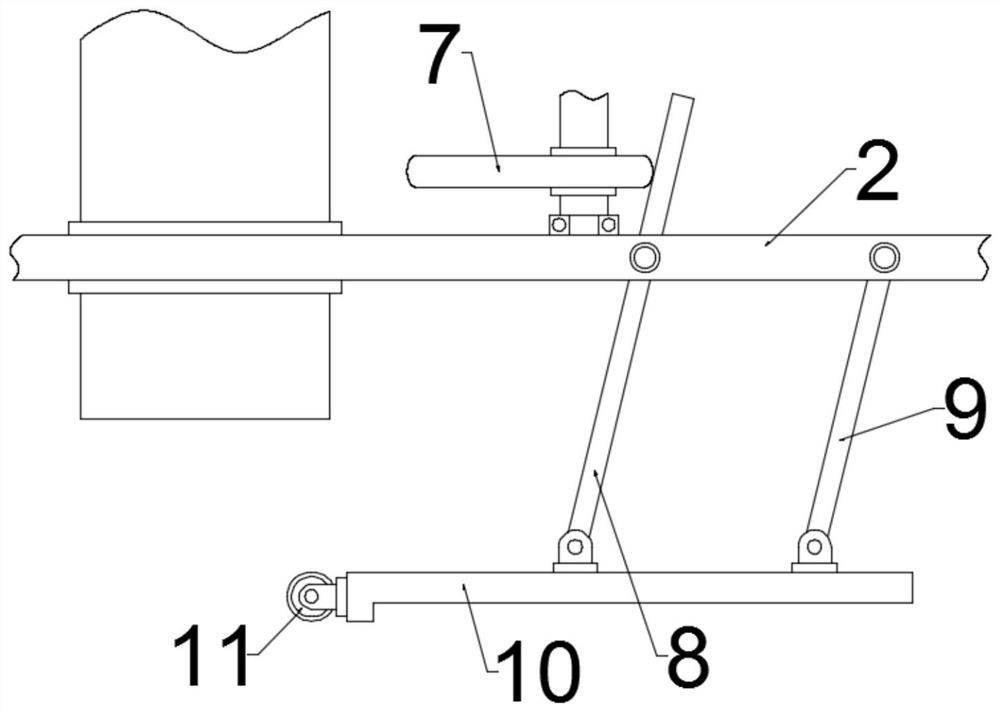

[0022] Further, the swing assembly includes a cam 7 fixed on the output shaft 6, an active lever 8 whose upper part abuts on the cam 7, a supporting plate 1...

Embodiment 2

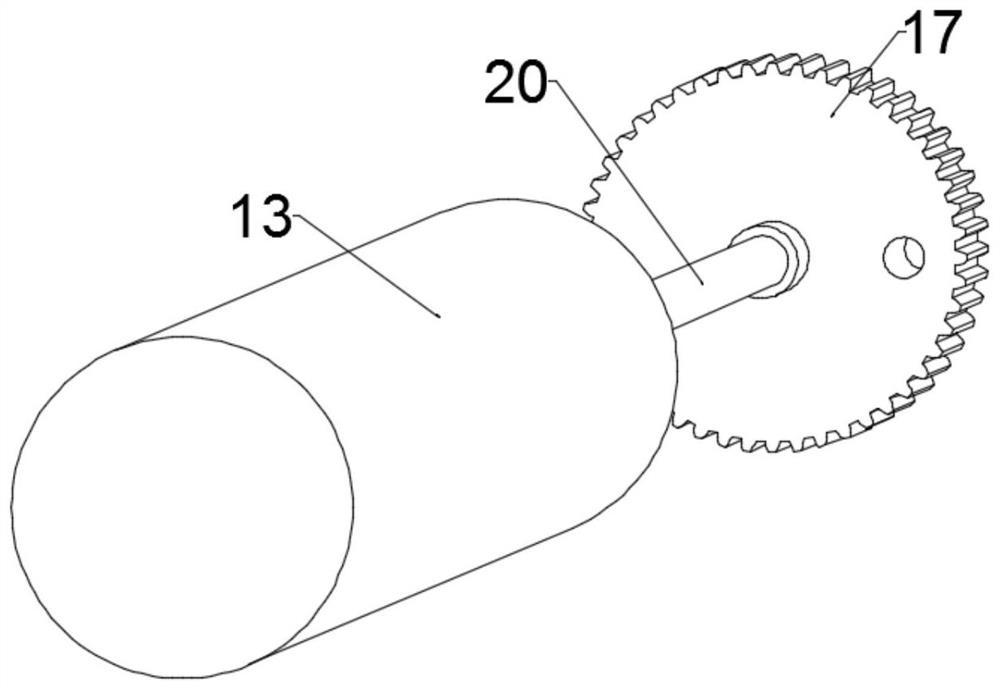

[0027] In order to further explain the above-mentioned sidewalk floor tile laying device for road construction, the present application provides another embodiment. A boom 20 is fixed at the center of the inner wall of the large gear 17, and the boom 20 is installed in the sandbox 13, and the suspension The upper end of bar 20 is rotatably connected on the cage, and the cage is fixed in the sandbox 13, and the height of bull gear 17 is fixed by cooperation of suspension rod 20 and cage.

[0028] A column is fixed above the rear portion of the vehicle plate 2, and the column is covered with a traction ring 19 connected with the traction tool. The equipment is connected to realize the movement of the device and achieve the function of moving brick laying and caulking.

[0029] According to the specific description of the above embodiment, it is easy to know that the working principle of the present invention is: turn on the switch to make the drive motor 5 energized to drive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com