Dust suppression equipment for construction site

A construction site, dust reduction technology, applied in the direction of using liquid separation agent, separation method, dispersed particle separation, etc., can solve the problems of inconvenient operation, low degree of freedom, etc., achieve large spraying range, improve atomization effect, and good dust reduction effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

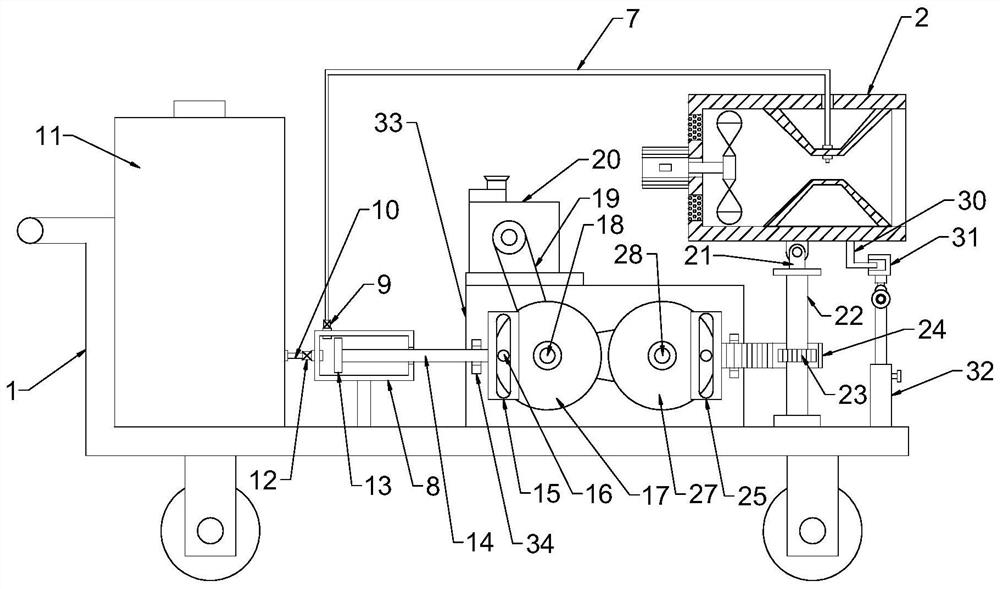

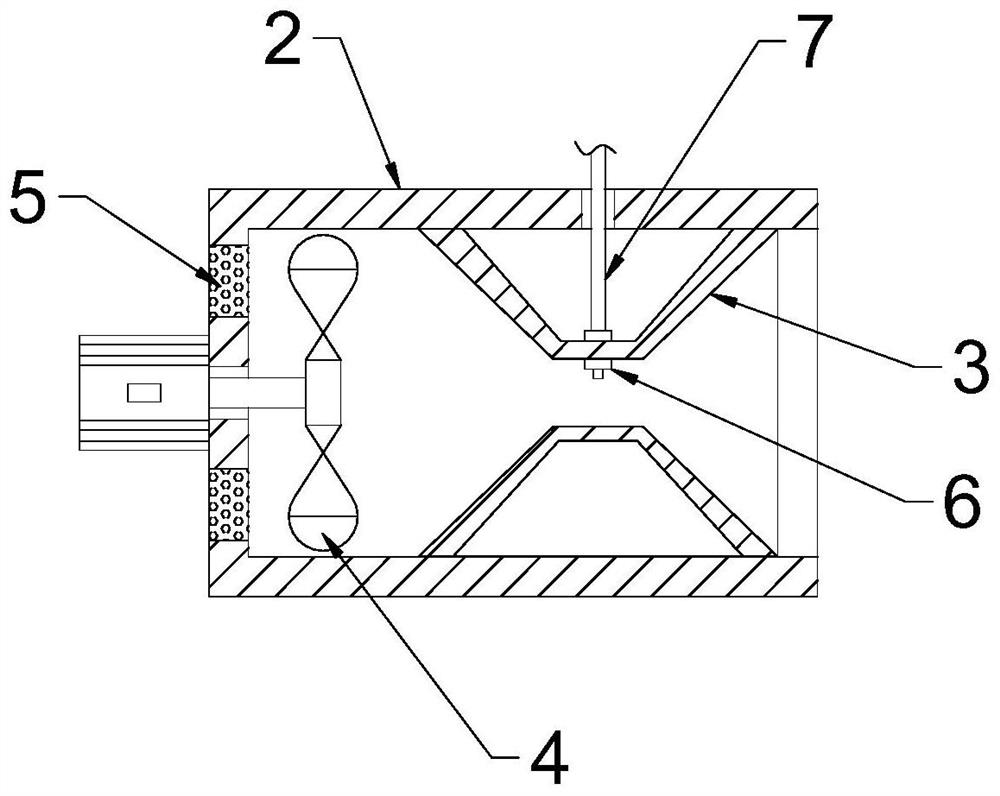

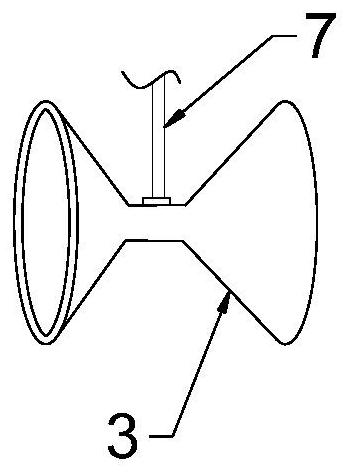

[0023] see Figure 1~2 , in an embodiment of the present invention, a construction site dust suppression equipment, including a car body 1, a spray tube 2, a piston barrel 8 and a diesel engine 20; the car body 1 is provided with rollers for easy movement; A spray tube 2 is provided, and the spray tube 2 is a cylindrical structure with an opening at the right end. A compression cover 3 is arranged inside the spray tube 2. The compression cover 3 is a hollow hourglass-shaped structure with both ends opened. The left side of the compression cover 3 is provided with a fan 4. The fan 4 is fixedly connected to the spray tube 2, the fan 4 is electrically connected to the external power supply, and the middle compression section of the compression cover 3 is provided with a nozzle 6, so that the clear water and the air flow collide at a high speed, and the atomization effect is improved;

[0024] The nozzle 6 is connected to the piston barrel 8 through the water inlet pipe 7, the wat...

Embodiment 2

[0028] see figure 1 with Figure 5 The difference between this embodiment and Embodiment 1 is: the front end of the spray tube 2 is fixedly connected with a guide rod 30, the guide rod 30 is a columnar rod, the guide rod 30 is nested with a guide groove plate 31, and the inside of the guide groove plate 31 is provided with The wave groove 3101, the front end of the guide rod 30 is nested in the wave groove 3101 and is slidably connected with the wave groove 3101, the guide groove plate 31 is an arc plate; 3101 moves so that the spray tube 2 swings up and down in the vertical plane, further improving the freedom of the spray tube 2 to swing, and improving the spraying range; A locking bolt is provided at the hinge to adjust the inclination angle of the guide groove plate 31, and the telescopic rod 32 is fixedly connected with the vehicle body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com