Inspection system for bottled chemical management and working method of inspection system

A patrol inspection system and chemical technology, which is applied in the field of patrol inspection system for bottled chemical management, can solve the problems of increasing potential safety hazards, administrators cannot directly obtain the storage status of chemicals, and cannot monitor chemicals in real time, so as to reduce safety Effects of reducing hidden dangers, contact probability, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

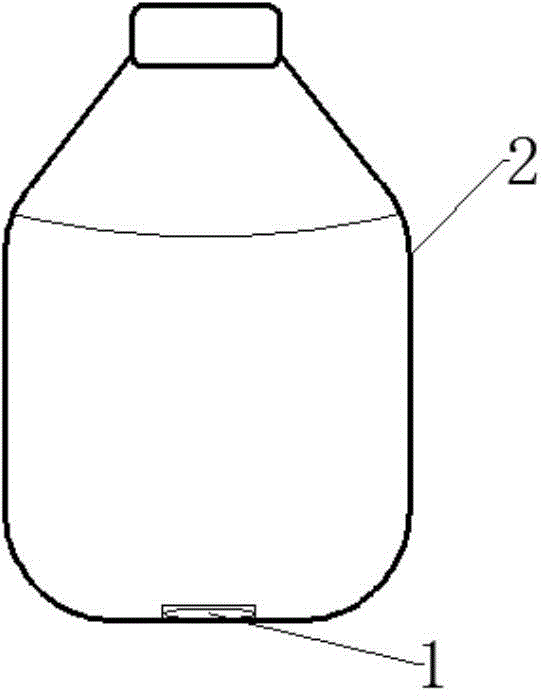

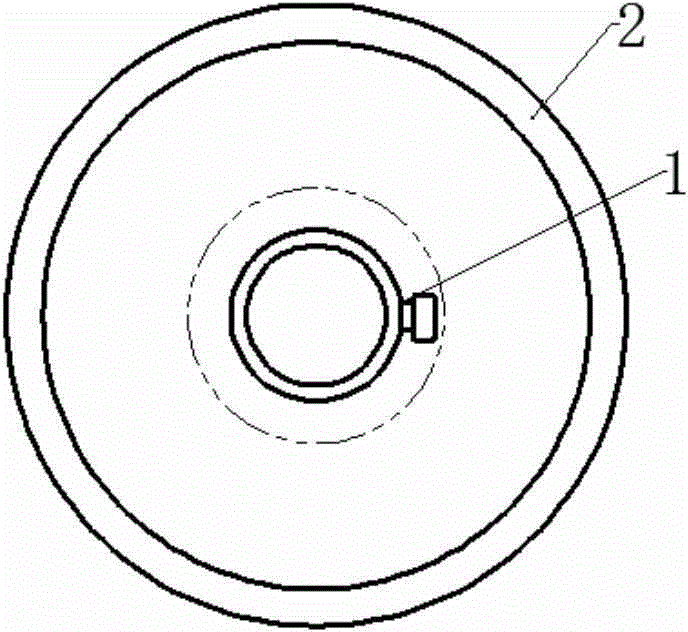

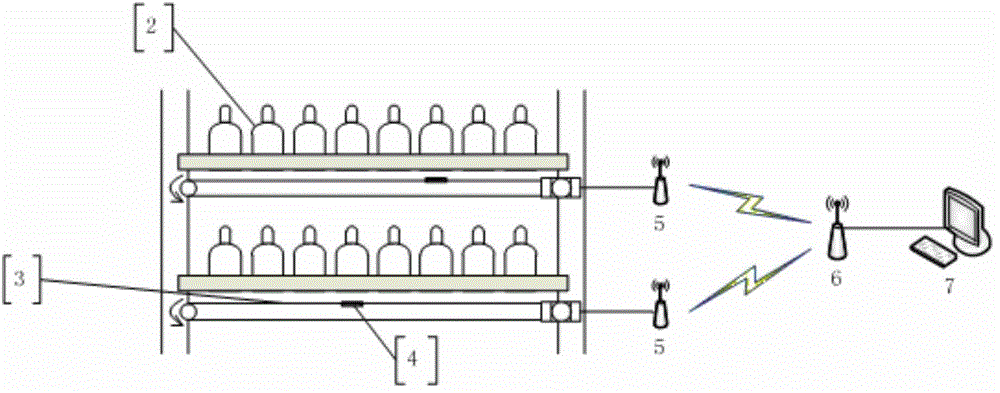

[0033]Embodiment: An inspection system for the management of bottled chemicals is characterized in that it consists of a radio frequency identification electronic tag 1 embedded in the bottom of the chemical packaging 2, an automatic inspection device 3, a wireless charging device, a circuit board 11 and The host computer control system 7 is composed; the automatic inspection device 3 includes a radio frequency identification read-write module 4, a ZigBee wireless sensor network node 5 and a ZigBee wireless sensor network terminal 6 for reading electronic tags, and the radio frequency identification reader Write module 4 corresponds to the position of radio frequency identification electronic tag 1, described radio frequency identification read-write module 4 and ZigBee wireless sensor network node 5 are connected by the circuit of circuit board 11, and described wireless charging device is radio frequency identification by circuit board 11 The read-write module 4 and the ZigBe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com