Business suit sleeve positioning and sewing method

A technology for professional wear and sleeves, which is applied in the field of garment processing, can solve the problems of difficult operation, low work efficiency, and increased production costs, and achieves the effects of simple operation, improved work efficiency, and improved clothing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

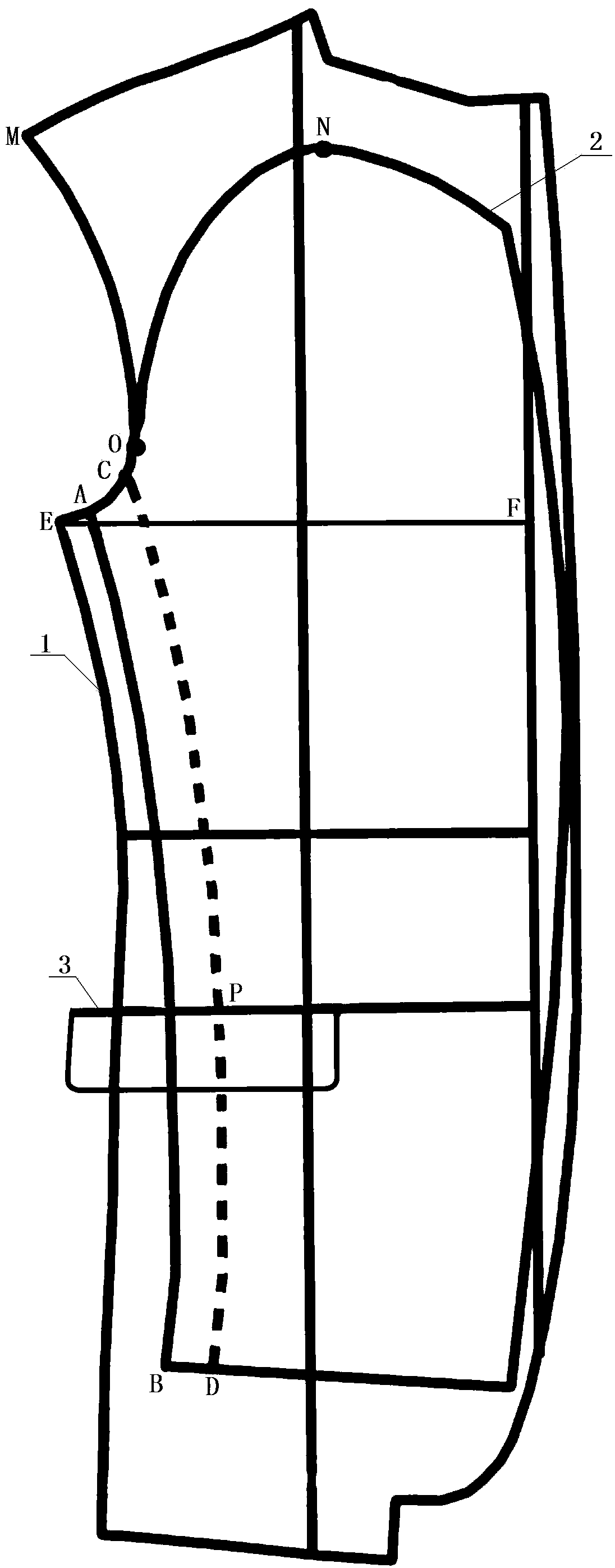

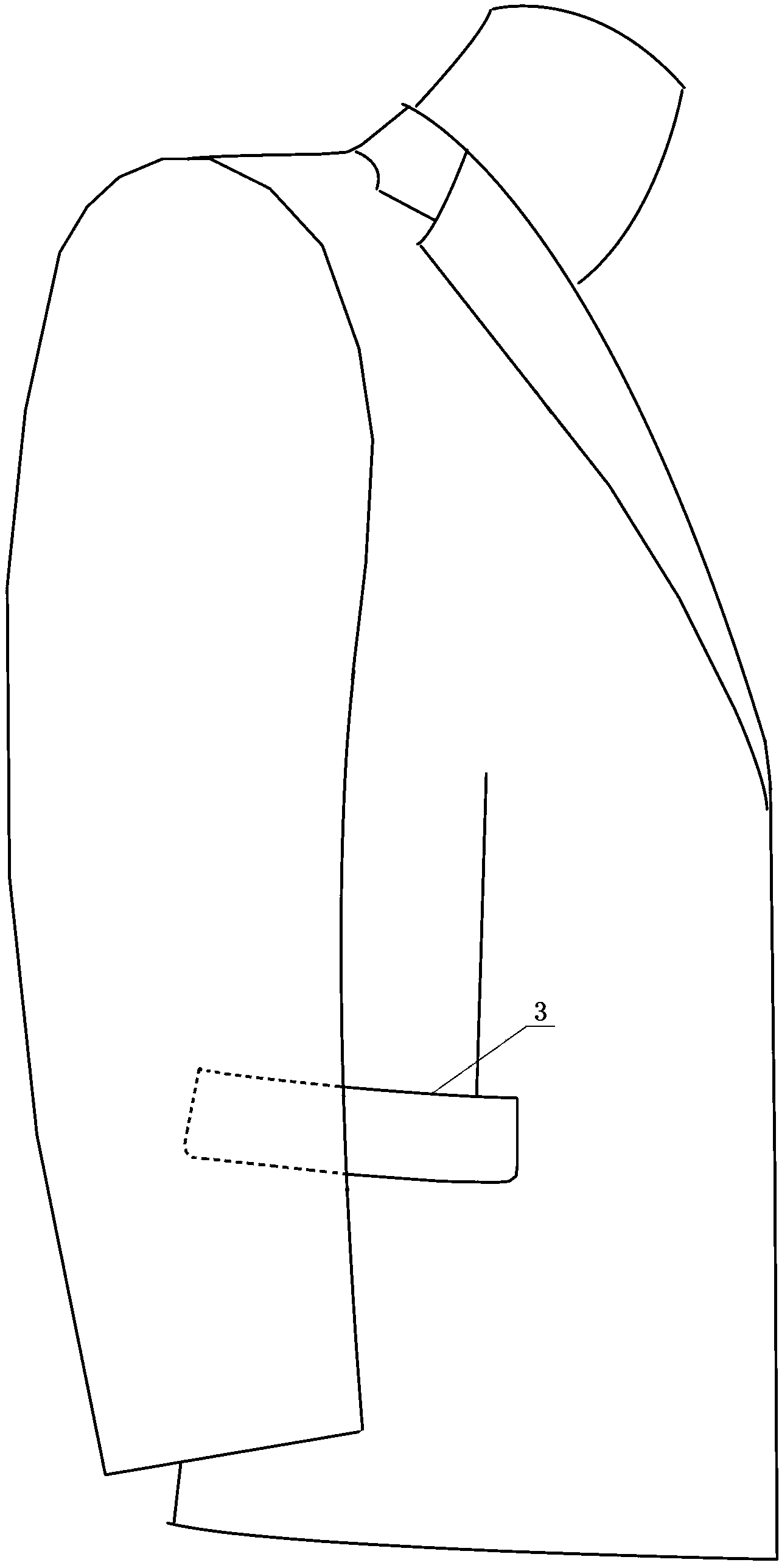

[0015] as attached figure 1 , 2 Shown, the present invention comprises front piece 1, big sleeve piece 2 and the big pocket cover 3 on the clothing body, and the inventive method adopts following processing steps:

[0016] 1. Place the cut large sleeve piece 2 on the front piece 1, so that the lower part of the front sleeve mountain arc of the big sleeve piece 2 corresponds to the lower part of the armhole arc of the front piece 1;

[0017] 2. Make the base line CD of the large sleeve 2 parallel to the inward 2.5-2.7 cm along the bottom suture line AB of the large sleeve 2;

[0018] 3. The bust line EF of the front piece 1 is horizontally upward 3.7-3.8cm and the arc of the armhole of the front piece 1 intersects at point O. Point O is the alignment cut point of the armhole of the front piece 1. Taking point O as the origin, turn the big sleeve Sheet 2, make the base line CD of the large sleeve sheet 2 intersect with the midpoint P of the large pocket cover 3 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com