A horizontal punching tool for pipe fittings

A technology for horizontal punching and pipe fittings, which is used in punching tools, manufacturing tools, metal processing equipment, etc. It can solve the problem of horizontal punching tooling without handrails, and achieve the effect of compact structure, high punching accuracy and long stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

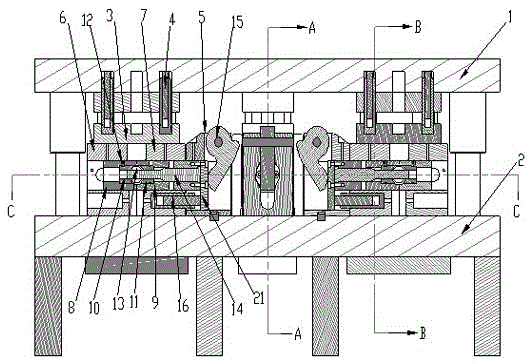

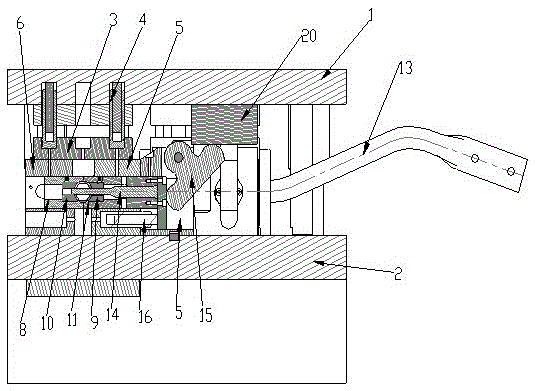

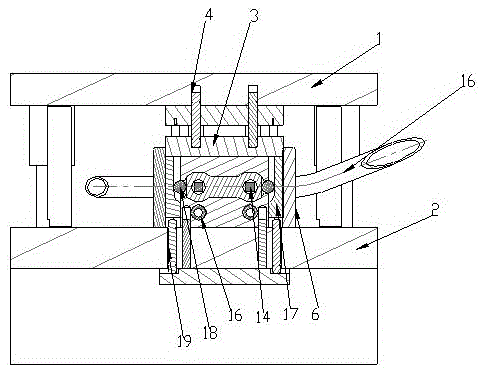

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention discloses a horizontal punching tool for pipe fittings, including an upper template 1, a lower template 2, and a guide post guide sleeve structure arranged between the upper template 1 and the lower template 2, the upper template 1 and the lower template 2 Several horizontal punching stations are set between them,

[0025] The lower end surface of the upper template 1 of each horizontal punching station is provided with an upper movable platen 3, and a buffer cylinder 4 is arranged between the upper movable platen 3 and the upper template 1; Strike block mounting seat 5, left die seat 6 and right die seat 7;

[0026] A groove A supporting the pipe fitting 13 is formed in the middle between the left die base 6 and the right die base 7, and the left movable block 8 and the right movable block 9 are respectively arranged in the left die base 6 and the right die base 7. Left movable b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com