Conveying mechanism used for stepwise-type all-dimensional valve cleaning machine

A conveying mechanism, a comprehensive technology, applied in the direction of conveyors, transportation and packaging, cleaning methods and appliances, etc., can solve the problems that the automatic cleaning or cleaning of the workpiece cannot be realized, the cleaning is not thorough, and the automatic transmission or rotation of the cleaned workpiece cannot be realized. Achieve the effect of avoiding incomplete cleaning and ensuring the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

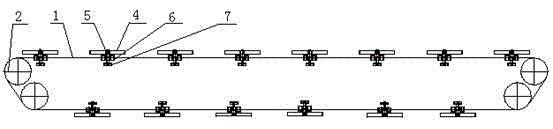

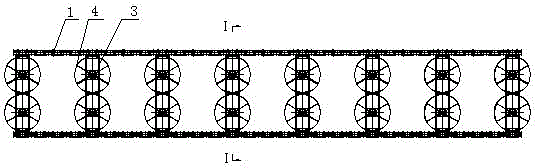

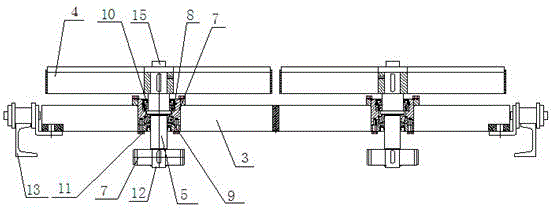

[0025] Such as figure 1 , figure 2 and image 3 As shown, this embodiment provides a conveying mechanism for a step-by-step all-round valve body cleaning machine, including a conveying chain 1, several guide gears 2, several pallets 4 for carrying workpieces, and a mechanism for fixing bearing seats 6. Several supporting plates 3, rotating shafts 5, bearing blocks 6 and rotating gears 7, the transmission chain 1 meshes with the guide gear 2, the two ends of the supporting plates 3 are respectively connected with the transmitting chain 1, and the middle part of the supporting plates 3 A bearing seat 6 is provided, and a bearing one 8 and a bearing two 9 are sequentially arranged in the bearing seat 6, and the rotating shaft 5 passes through the tray 4, the bearing one 8, the bearing two 9, the rotating gear 7 in sequence, and the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com