A sewing machine mop wheel device

A cloth mopping wheel and sewing machine technology, which is applied in the field of sewing machines, can solve the problems of insufficient uniformity of stitches, inconsistent stitches, influence on aesthetics, etc., and achieve the effects of good mopping effect, uniform stitches and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

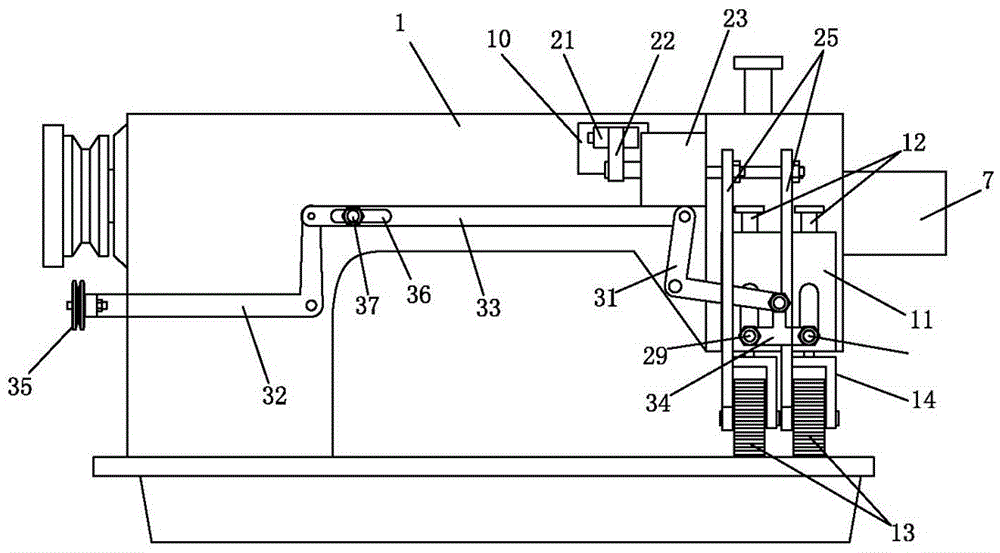

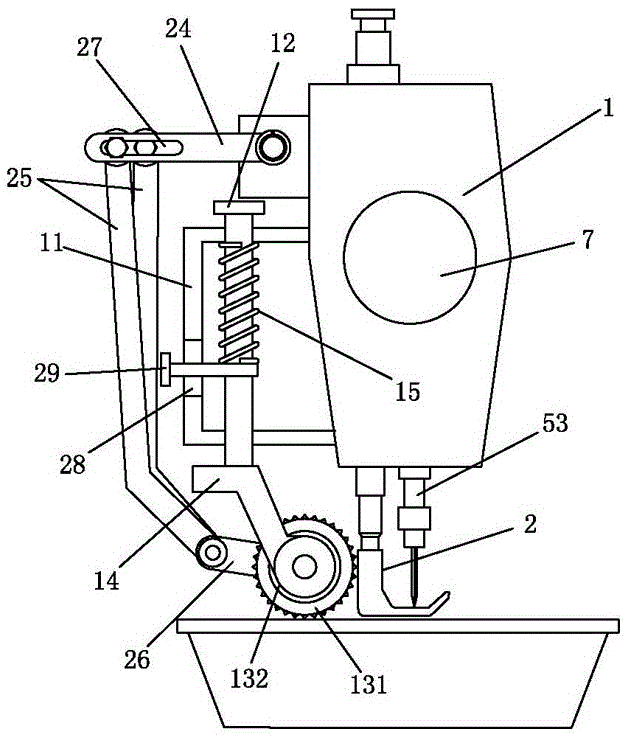

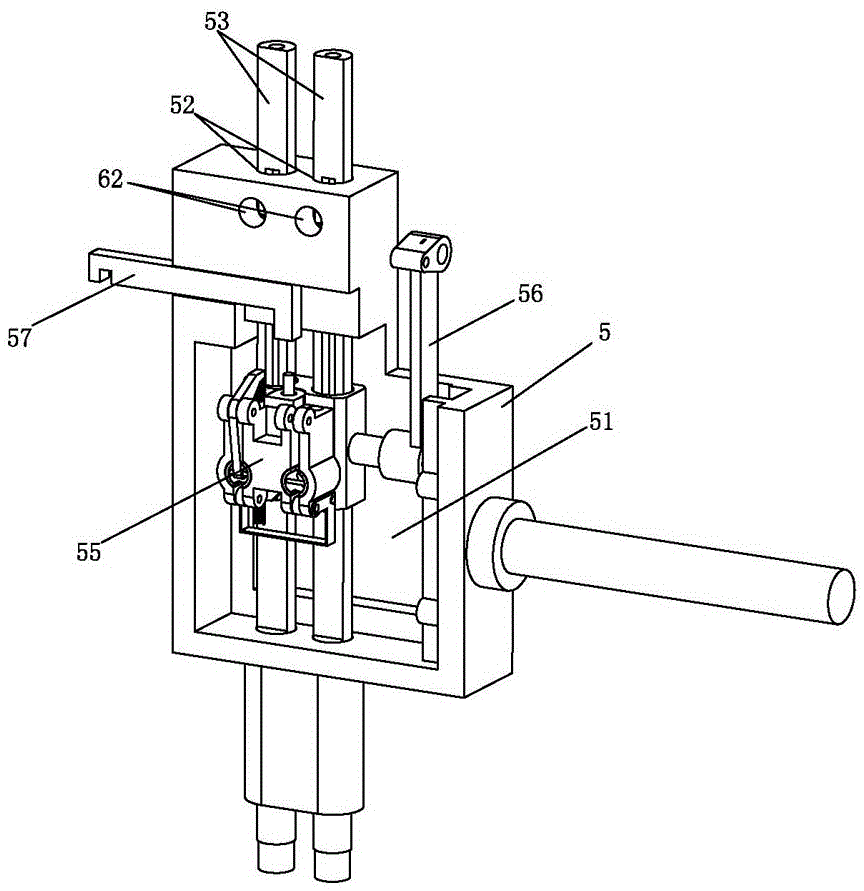

[0019] Such as Figure 1-8 As shown, a sewing machine mop wheel device includes a sewing machine head 1 and a presser foot 2, and a mop wheel device is arranged on the back of the sewing machine head, and the mop wheel device includes a box body 11, a mop wheel pressing bar 12, a single To the mop wheel 13 and the link mechanism, the box body 11 is fixedly connected to the back of the sewing machine head 1, and two mop wheel pressure bars 12 arranged in parallel pass through the box body 11 from top to bottom, and each mop wheel presses The lower ends of the rods 12 are provided with mop wheel brackets 14, and each mop wheel bracket 14 is provided with a one-way mop wheel 13, and a spring 15 is sleeved on the mop wheel pressure rod 12, and the spring 15 is accommodated in the box 11 Apply downward pressure on the mop wheel pressure bar 12; the one-way mop wheel includes a mop gear 131 and a one-way ratchet 132, the mop gear 131 is sleeved on the one-way ratchet 132, and the on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com