An electric sunshade louver

A louver, electric technology, applied in the direction of shading screens, etc., can solve the problems of laborious operation, low degree of automation of venetian blinds, and manual stage of venetian blinds, so as to achieve the effect of improving performance and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

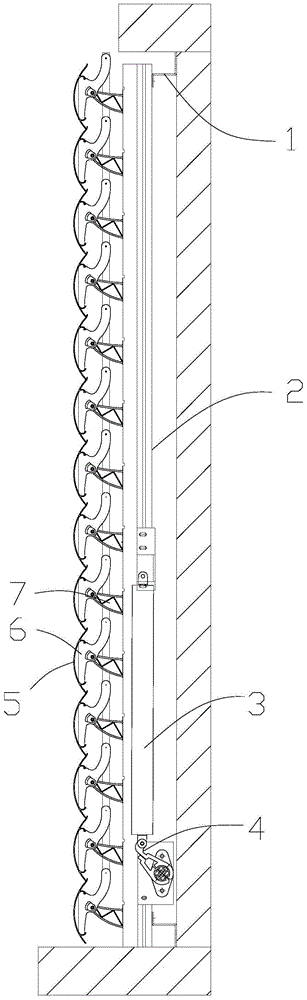

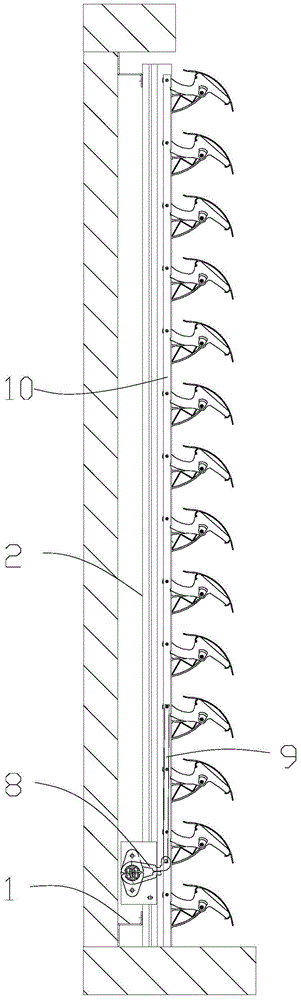

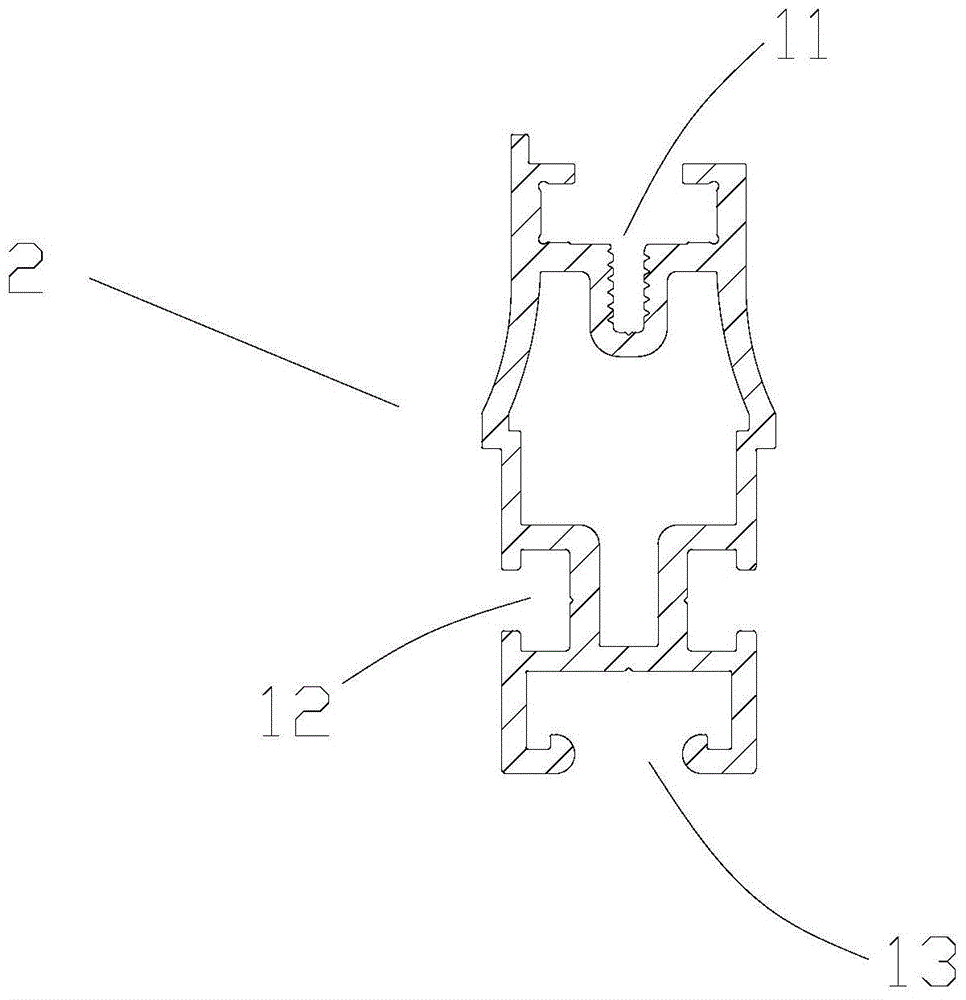

[0038] see Figure 1 to Figure 2 , this embodiment discloses an electric sunshade louver, comprising: a mounting flange 1, a column 2, an electric cylinder 3, a controller, a driving mechanism, a louver base 7, a movable block 6 and a louver blade 5; at least two columns 2 Installed vertically, the back of the column 2 is equipped with a mounting flange 1; the louver base 7 is equidistantly installed on the front of the column 2; the middle part of the movable block 6 is hinged with the end of the louver base 7; the louver 5 is installed on the movable On the block 6; the tail of the electric cylinder 3 is hinged with one of the columns 2, the end of the telescopic rod of the electric cylinder 3 is connected to the drive mechanism, and the drive mechanism is connected to the tail of the movable block 6; the controller is connected to the electric cylinder 3.

[0039] Mounting flange 1 is used for the installation of electric sunshade shutters. When the user controls the elect...

Embodiment 2

[0050] see Figure 5 The only difference between this embodiment and Embodiment 1 is that the surface of the louver 5 is planar, and the back of the louver 5 is provided with a mounting part, and the louver 5 is installed on the movable block 6 through the mounting part on the back; The upper side of the louver 5 is provided with a groove bent toward the back of the louver 5 , and the groove is a connecting groove 15 ; the lower side of the louver 5 is provided with a connecting portion 16 protruding toward the back of the louver 5 .

[0051] In this embodiment, the planar louver 5 is used instead of the convex arc louver 5 , and the upper side of the louver 5 is still provided with a connecting groove 15 . The lower side of the upper louver 5 is inserted into the connection groove 15 of the lower louver 5 through the connecting portion 16 . There is no distinction between the technical solution of the present embodiment and the technical solution of the first embodiment, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com