Double-position valve applied to draught fans

A two-position valve and fan technology, applied in the field of two-position valves, can solve problems such as difficult water supply and waste of water resources, and achieve the effects of avoiding corrosion of the valve casing, shortening the service life, and sensitive flap movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

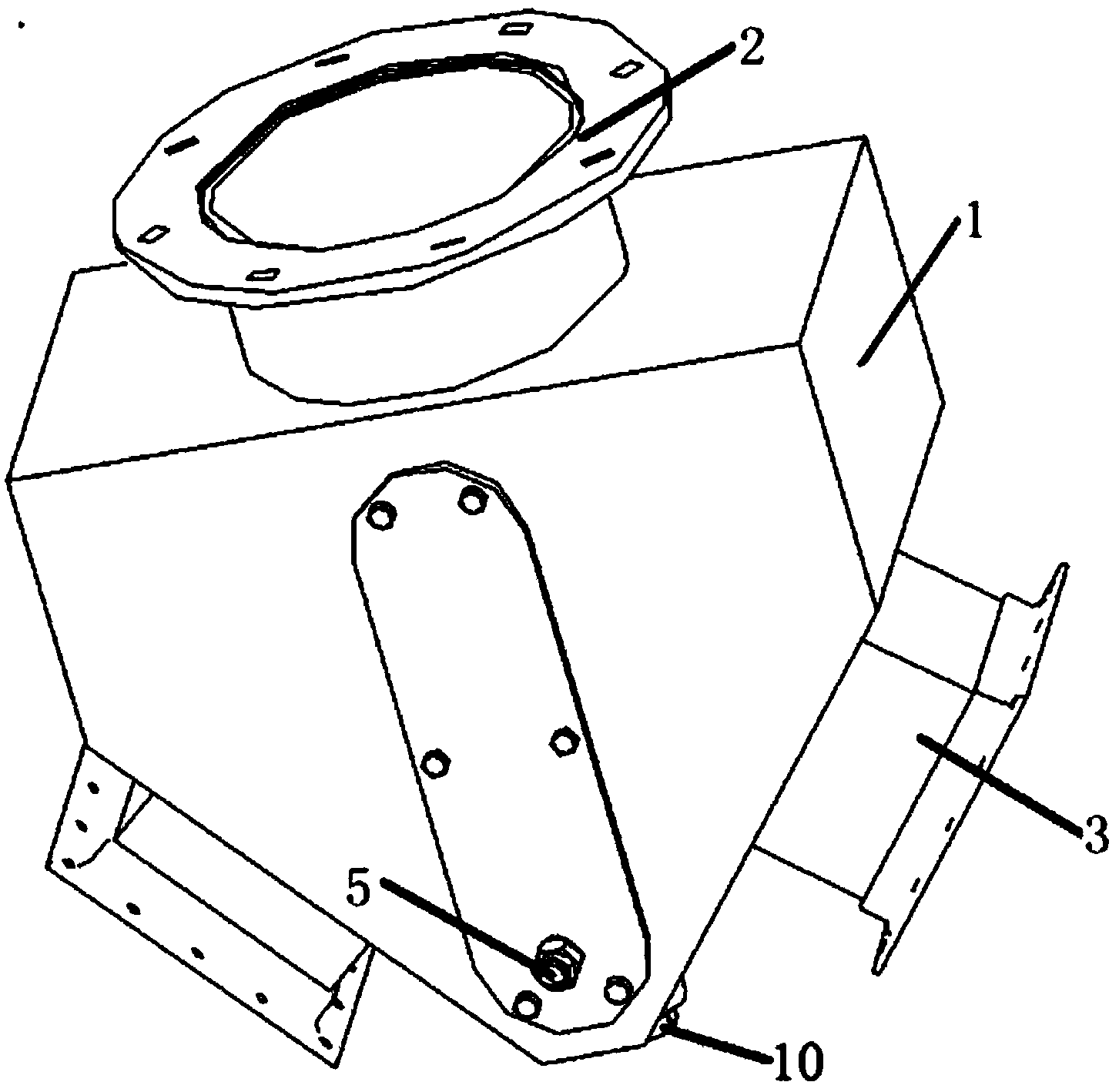

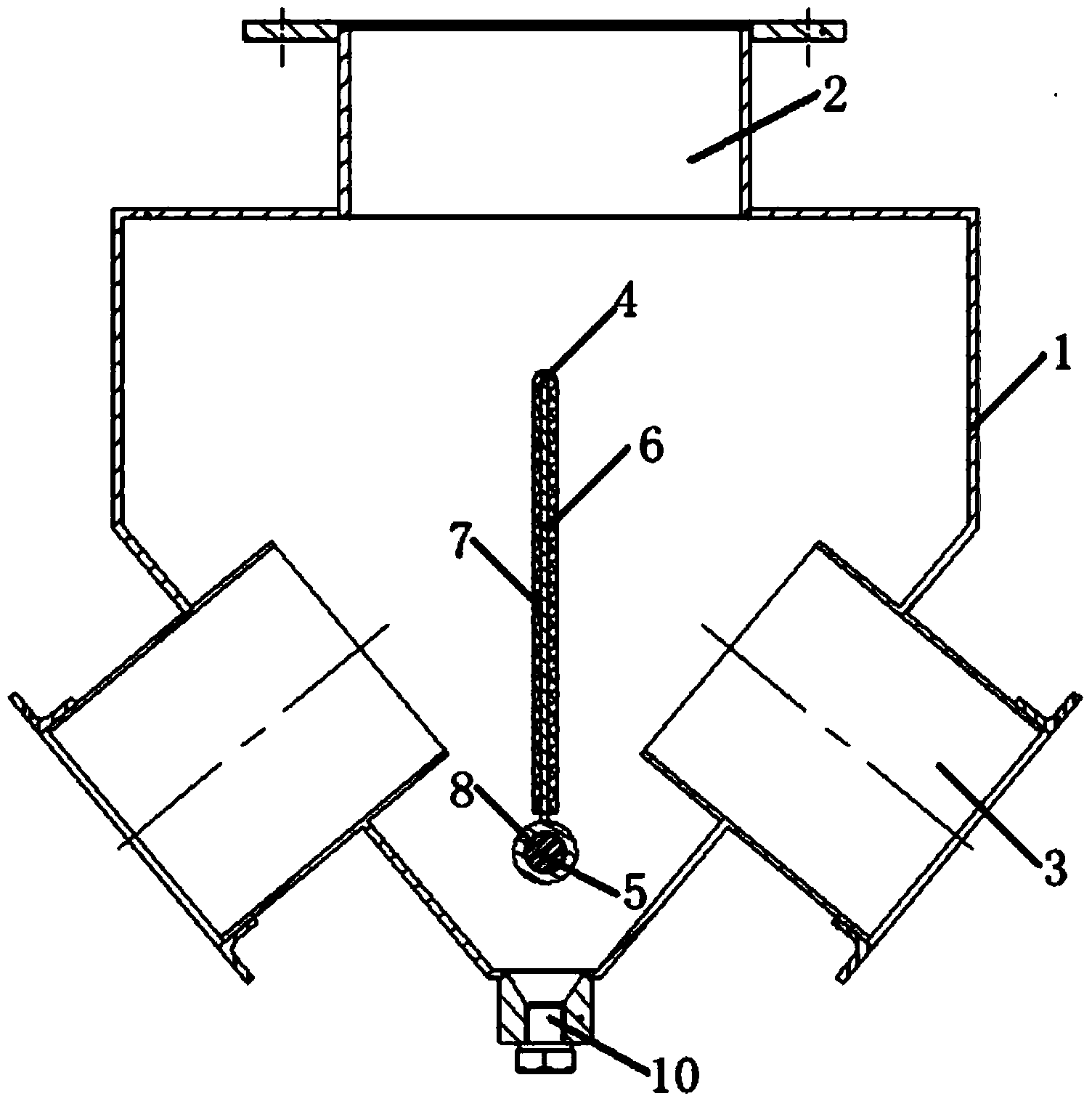

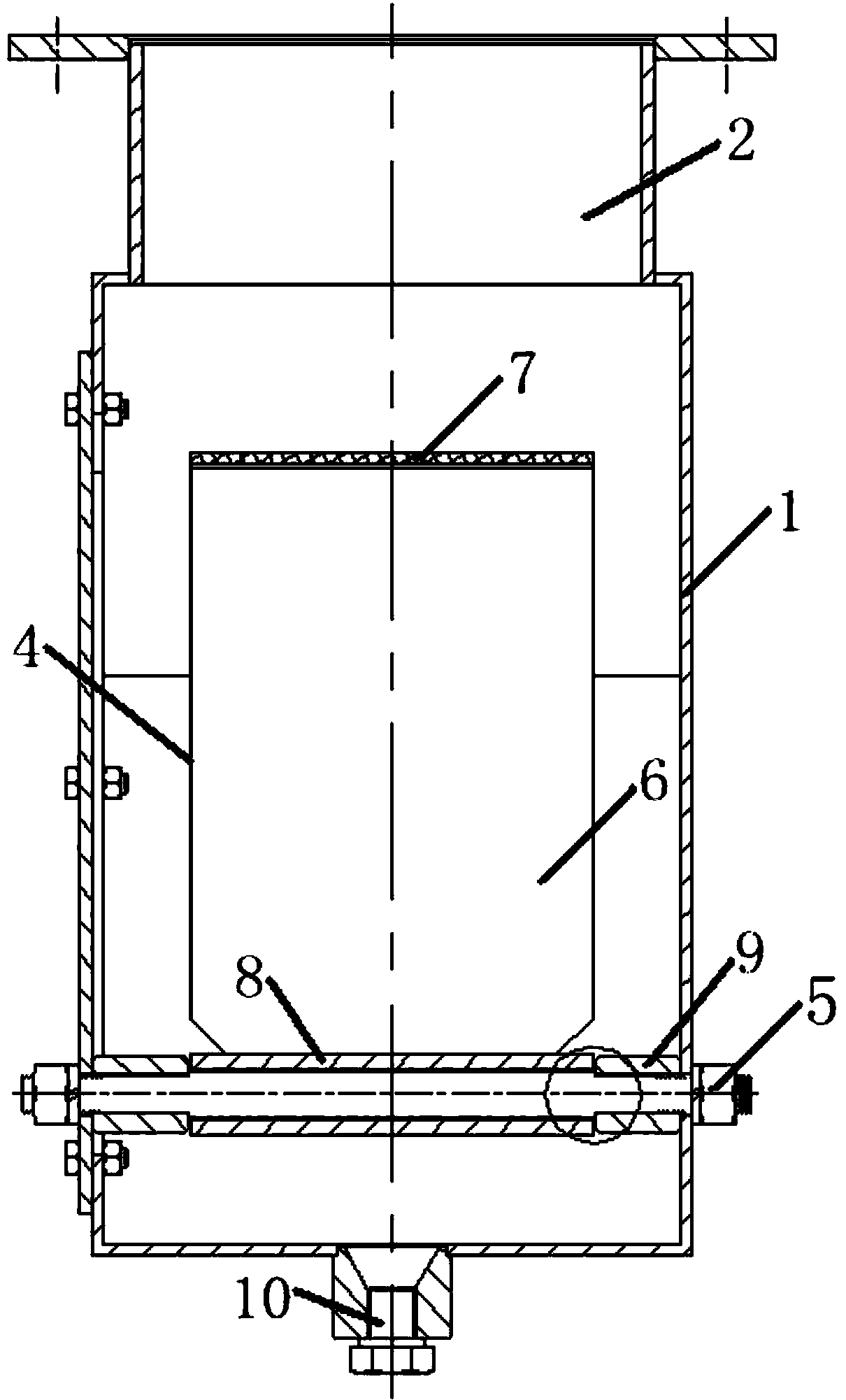

[0020] see Figure 1-Figure 4 , a two-position valve applied to fans, including a valve casing 1, on which an air outlet 2 and two air inlets 3 are arranged, the air outlet 1 is located on the center line of the valve casing 1, and the inlet The air port 3 is symmetrically arranged left and right along the center line of the valve casing 1. The valve casing 1 is provided with a flap 4 inside. The flap 4 includes a steel plate 6 and a wrapped rubber 7. The flap 4 is located on the center line of the valve casing 1. Set on the pin shaft 5, the pin shaft 5 is fixed on the cover plate through the pin shaft locking nut, and the cover plate is fixed on the valve casing 1 through the cover locking bolt. There is a gap of 3-5 mm between the flap sleeve 8 on the flap 4 and the pin shaft 5, and a gap of 3-5 mm is provided between the end face of the flap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com