Triggering switch-over device

A conversion device and mechanical technology, applied in emergency protection devices, contact operating parts, electrical components, etc., can solve the problems of poor conversion consistency of mechanical micro switches, inability to accurately transmit elastic deformation, and absorb overpressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

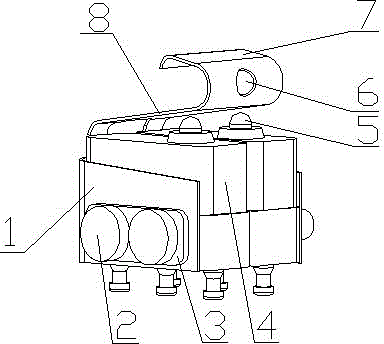

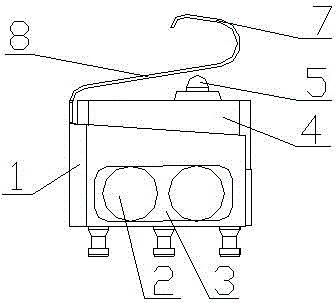

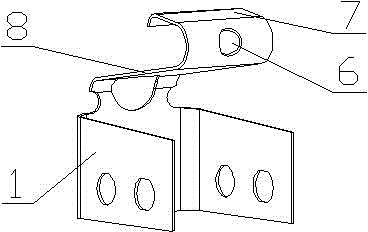

[0018] The specific implementation, structure, features and functions of the trigger conversion device according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0019] see Figure 1 to Figure 5 , the trigger switching device of the present invention includes a spring piece 1 and a mechanical microswitch 4, the spring piece 1 is fixed on the mechanical microswitch 4, wherein: the spring piece 1 is provided with a first bending part 7 and a second Two bending parts 8, wherein the second bending part 8 is matched with the mechanical micro switch button head 5, and there is at least one mechanical micro switch 4. There are two mechanical micro switches 4 . The spring piece 1 is provided with several crack relief openings 6 . The spring piece 1 is fixed on the mechanical micro switch 4 by the rivet 2 and the washer 3 .

[0020] During use, a corresponding pressing force is applied to the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com