Wiper blade, wiper arm and connection mechanism for vehicle wiper equipment

一种雨刮片、雨刷臂的技术,应用在雨刮片领域,能够解决保持、雨刮片拆卸操作复杂、雨刮片不再可靠等问题,达到简化拆卸及更换操作的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

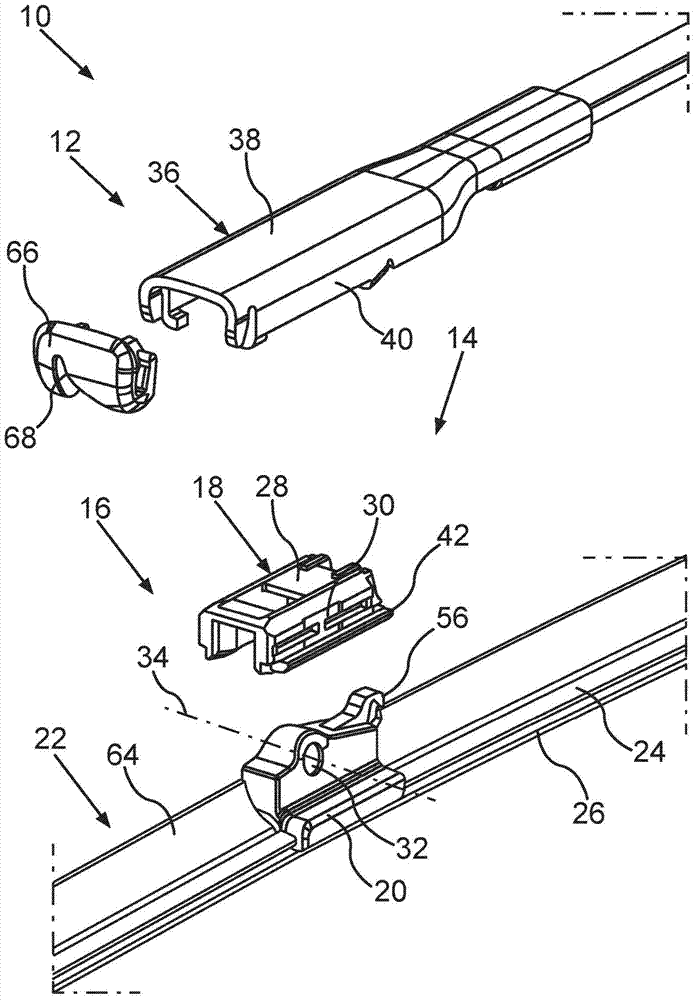

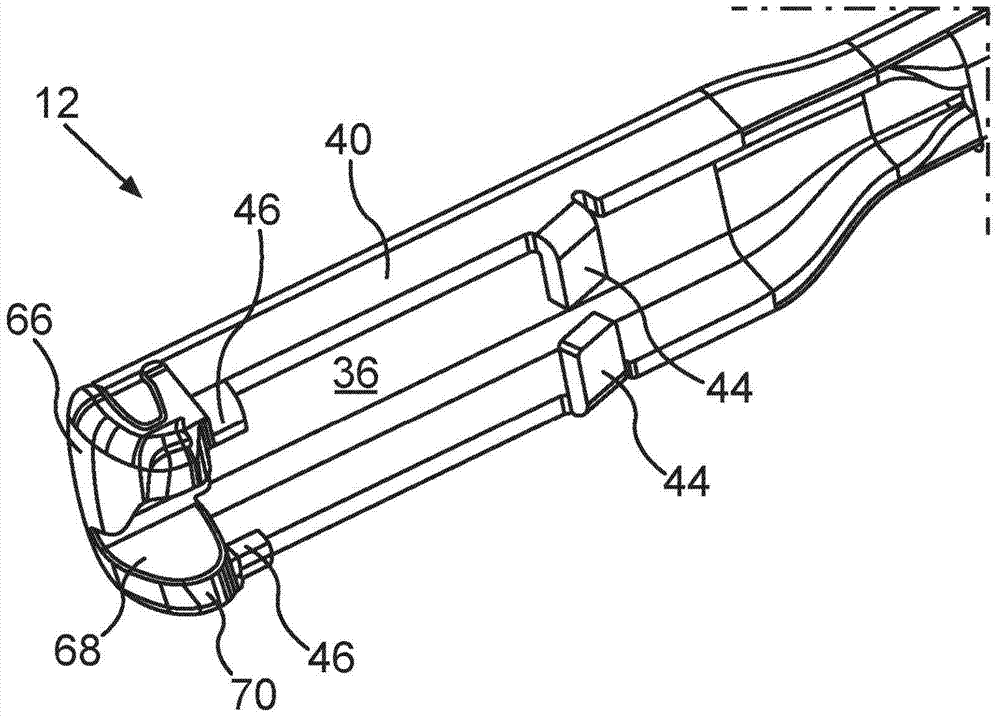

[0037] figure 1 The assembly of the wiper arm 12 and the wiper blade 14 of the connecting mechanism 10 of the vehicle wiper device is shown in a perspective view. An engaging element in the form of an adapter 16 is used to fix the wiper blade 14 to the wiper arm 12.

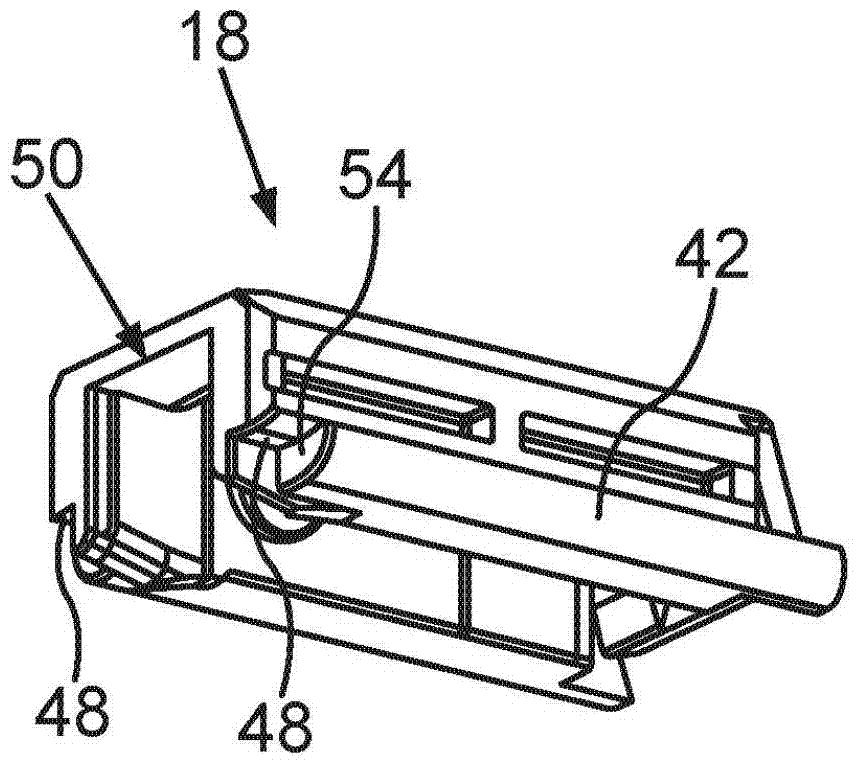

[0038] The adapter 16 includes an upper part 18 having a U-shaped cross section, and a lower part in the form of a slider 20 that holds the body 22 of the wiper blade 14. In this case, the body 22 includes the elastic guide rail 24 and the wiper lip 26 of the wiper blade 14. The upper part 18 of the adapter 16 includes a back 28 and side edges 30 connected to the back 28. A metal pin (not shown) is held on the side 30 of the upper part 18, and the upper part 18 (see Figure 5 In ), the metal pin penetrates the through hole 32 formed in the sheet-shaped area of the slider 20. With the help of the metal pin supported in the through hole 32, a rotating shaft 34 is provided.

[0039] In this way, the slider 20 togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com