Display base frame forming machining device and method

A molding processing and display technology, applied in metal processing equipment and other directions, can solve the problems of poor deformation resistance of the overall structure, occupy a large space, consume materials, etc., and achieve the effects of strong deformation resistance, high production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

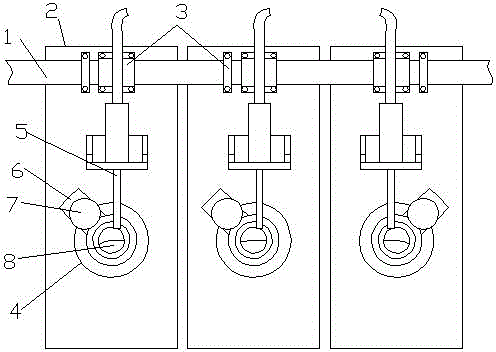

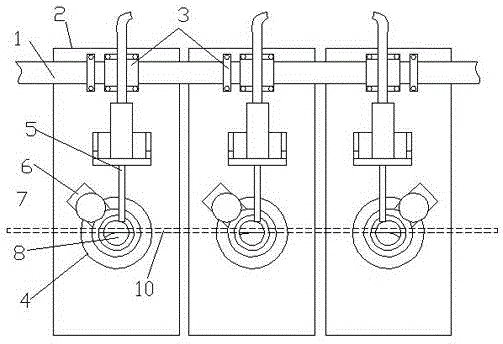

[0026] Such as Figure 1~5 As shown, a display stand frame forming processing device includes a circular guide rod 1 arranged transversely on the frame, and several processing bases 2 are arranged on the rear side of the circular guide rod 1, and the processing bases 2 pass through the buckle Part 3 is fixed on the round guide rod 1 and can slide left and right relative to the round guide rod 1. The processing base 2 is provided with a bending device 4 for bending the workpiece. A pressure rod 5 that can move downwards to compress the workpiece 10 is arranged above the device 4 .

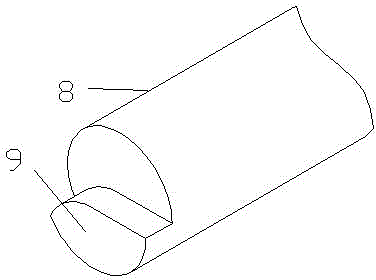

[0027] In this embodiment, the bending device 4 includes a rotating rod 6 with a bending wheel 7, the rotating rod 6 is driven by an air cylinder to perform a rotational movement relative to the processing base 2, and the rotating rod 6 is provided with Perpendicul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com