Filter component for air conditioner/refrigerator and manufacturing process thereof

A filter assembly and manufacturing process technology, applied in the field of air conditioner/refrigerator filter assembly and its manufacturing process, can solve problems such as waste of raw materials, hidden dangers of leakage, environmental protection, easy to break, etc., and achieve extended service life, rapid integrated molding, The effect of solving refrigerant leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

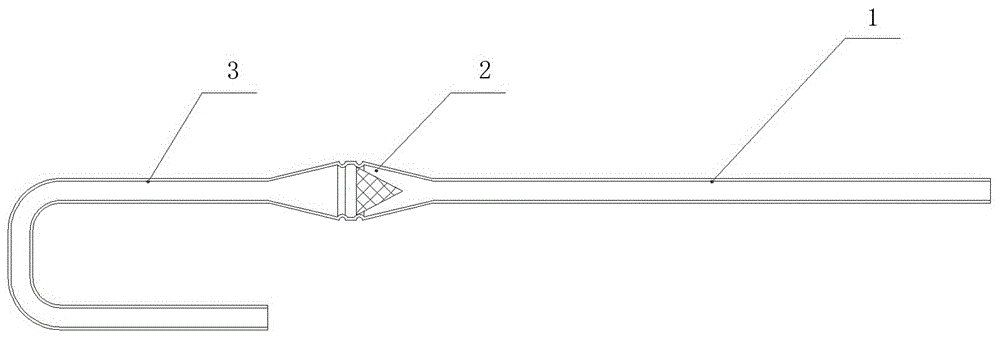

[0014] according to figure 1 As shown, a filter assembly for an air conditioner / refrigerator of the present invention includes a branch pipe I1, a filter 2, and a branch pipe II3, and the side of the filter 2 near the branch pipe I1 is provided with a filter screen, and the branch pipe I1, filter 2, Branch pipe II3 is an integral component.

[0015] The branch pipe I1, the filter 2 and the branch pipe II3 of the present invention are copper tubes, and the filter screen is stainless steel.

[0016] A kind of manufacturing process of air conditioner / refrigerator filter assembly of the present invention, comprises the following steps:

[0017] a) First, make the round tube into the required diameter, wrap the top of the filter screen with copper skin and send it into the round tube, radially spin grooves on the outer diameter of the round tube at the corresponding position of the filter screen, and fix the top of the filter screen;

[0018] b), and then spinning and drawing the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com