Bamboo-plastic strip elbow mold-pressing process and device

A bamboo-plastic and elbow technology, applied in the field of bamboo-plastic strip elbow film pressing technology and equipment, can solve the problems of high cost, expensive injection mold, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

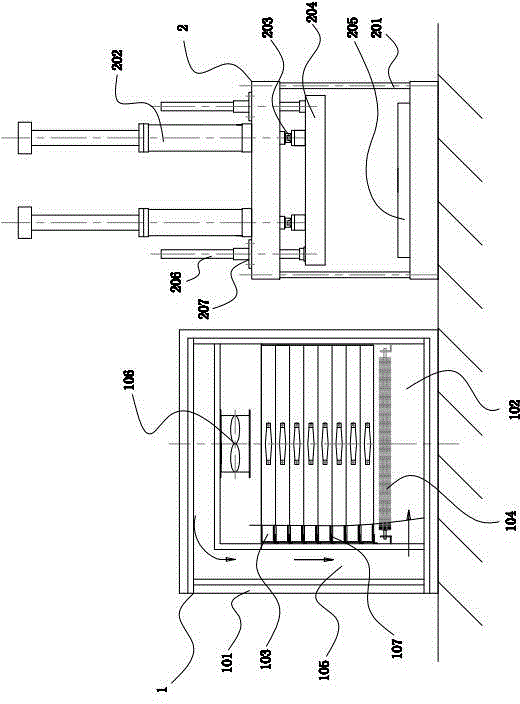

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0020] See attached Figures 1 to 3 , the bamboo-plastic strip elbow membrane pressing process in the figure is characterized in that it includes the following steps:

[0021] The first step is to make a mold and carve an elbow mold with MDF;

[0022] The second step is to prepare bamboo-plastic soft strips, cut the formed bamboo-plastic straight strips into the required design size, and then put them into a heating box for heating. The heating temperature is 80-130°C, and the heating time is 12-18 minutes. Make bamboo-plastic straight strips into bamboo-plastic soft strips;

[0023] The third step is compression molding, put the bamboo-plastic soft strip described in the second step into the elbow membrane tool described in the first step, and then pressurize the elbow membrane tool through a pressurizing device, so that the bamboo-plastic soft strip The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com