Laser transmission welding clamping apparatus capable of achieving any curved surface welding

A laser transmission welding and clamping device technology, applied in the field of laser welding, can solve the problems of glass ball surface wear, stress concentration, uneven clamping force, etc., to improve quality, uniformly distribute pressing force, and avoid stress concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

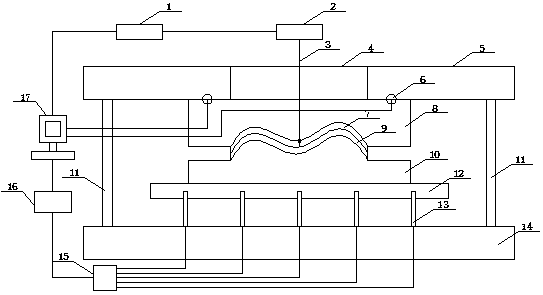

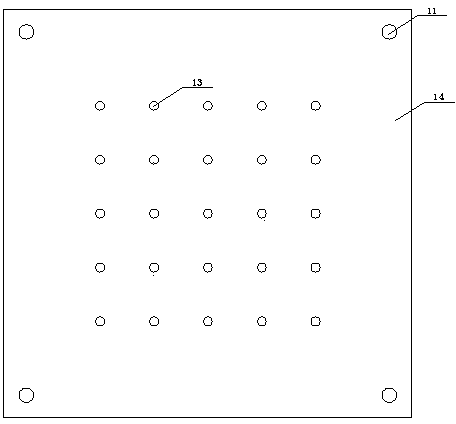

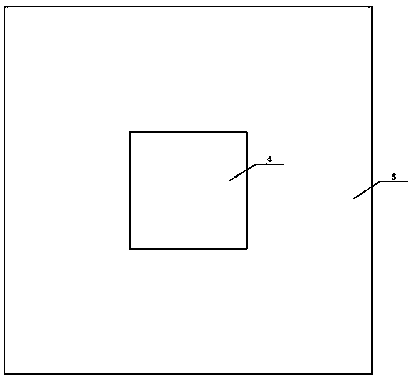

[0021] Such as Figure 1-3 shown.

[0022] A laser transmission welding clamping device capable of welding any curved surface, which includes a PC 17, a PLC controller 16, a hydraulic system 15, a pressure sensor 6, an upper top plate 5 and a lower bottom plate 14, such as figure 1 As shown, the hydraulic system 15 is controlled by the PLC controller 16, the PLC controller 16 is controlled by the PC 17, the pressure sensor 6 is electrically connected to the PC 17, and the hydraulic small thimble 13 is installed on the lower base plate 14, so The oil inlet pipeline and the oil return pipeline of the hydraulic small thimble 13 are respectively connected to the solenoid valve of the hydraulic system 15, the signal control line of the solenoid valve of the hydraulic system 15 is connected to the PLC controller 16, and the lower base plate 14 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com