Centrifugal membrane mechanism of laminating equipment

A technology of film sticking equipment and centrifugal film, which is applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the problems of poor accuracy, no guarantee of operation accuracy, and high labor intensity, so as to avoid human error and improve operation efficiency , Improve the effect of working accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, thereby making a clearer definition of the protection scope of the present invention

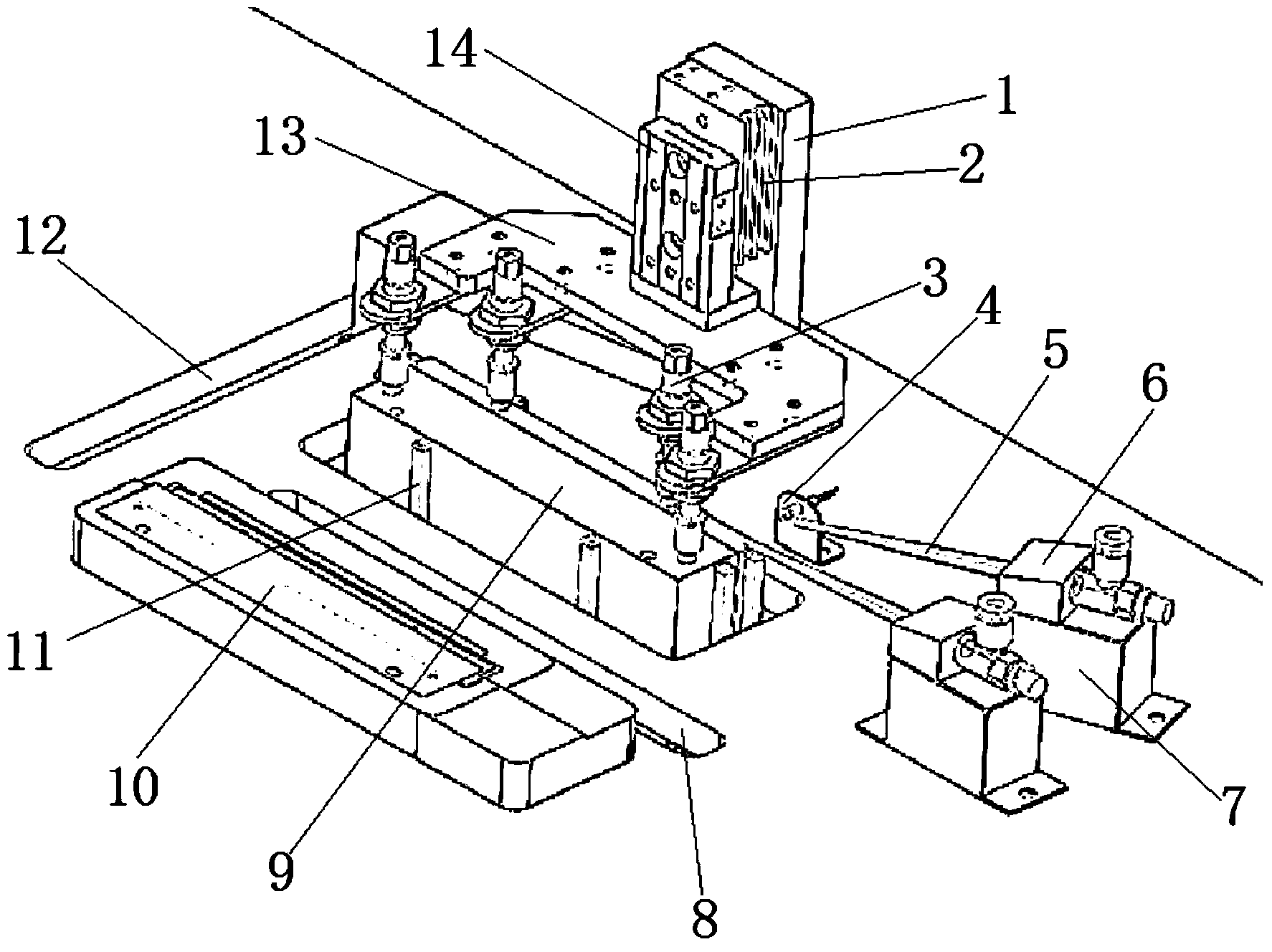

[0015] Such as figure 1 As shown, a centrifugal film mechanism of a film sticking device includes a support plate 1, a telescopic rod 2 arranged in front of the support plate 1, a fixed frame 14 arranged in front of the telescopic rod 2, and a film arranged below the fixed frame 14. The sheet transplanting part 13, and the diaphragm grabbing nozzle 3 arranged in front of the diaphragm transplanting part 13, and the sensor 4 arranged on the right side of the diaphragm grabbing nozzle 3, and the air gun arranged on the right side of the sensor 4 Pipe 5, and the ion air gun 6 that links to each other with air gun pipe 5, and the air gun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com