A tvs tube type high-efficiency electrostatic protection bridge wire electric detonator

A technology of electrostatic protection and electrostatic protection devices, which is applied in the direction of weapon accessories, fuzes, offensive equipment, etc., and can solve problems such as danger, large size, and unproposed product size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

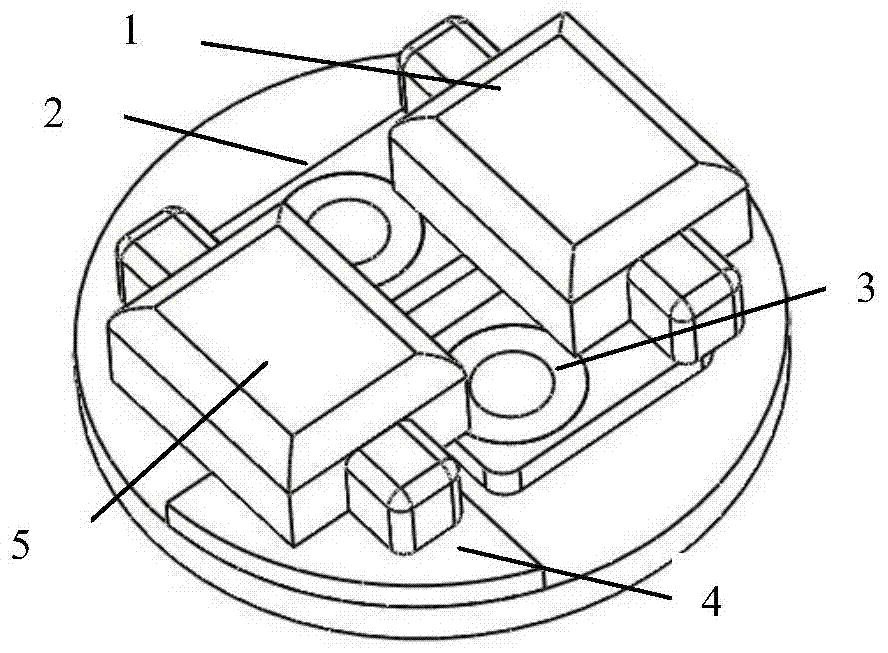

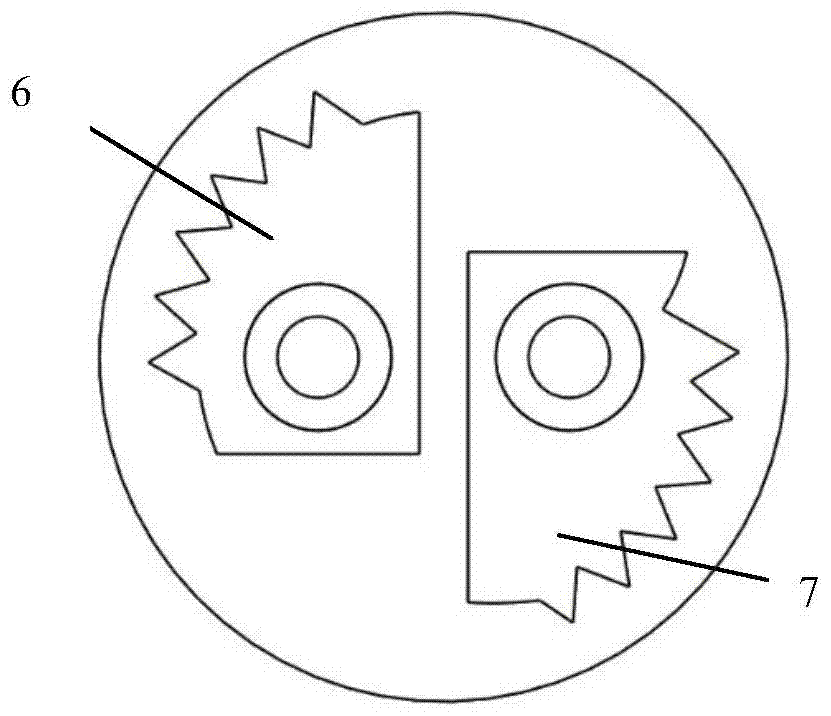

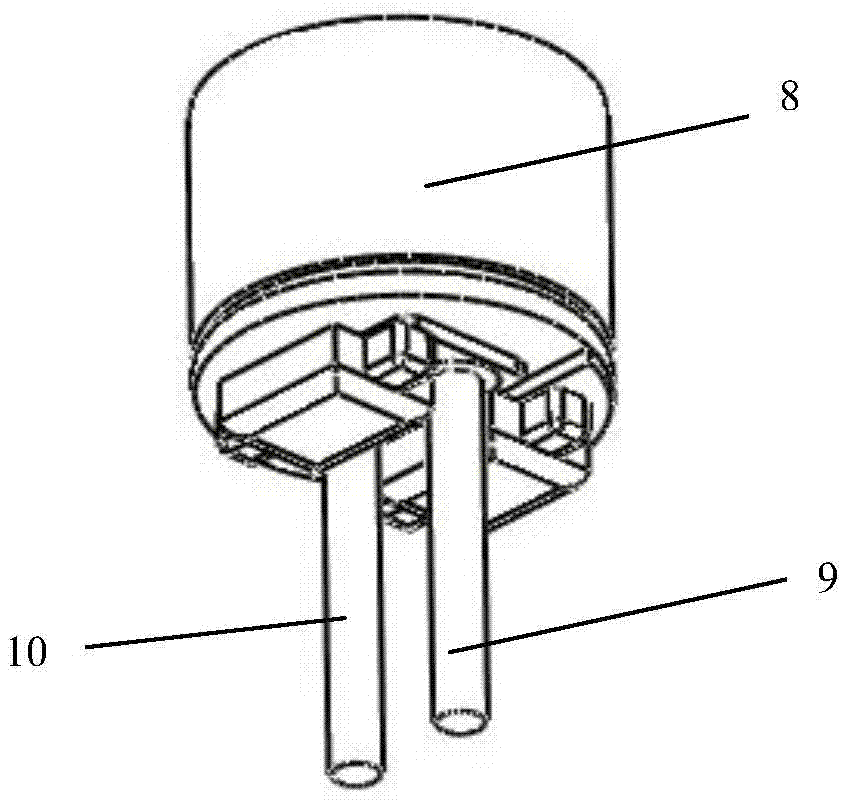

[0024] combine image 3 , Figure 4, the bridge wire electric detonator of the patent anti-static environment of the present invention includes TVS tubes 1 and 5 with XXX type, disc-shaped electrostatic protection PCB circuit board, electrode plug 8, bridge wire, propellant, priming charge, output charge, and shell 11. Connect one side of the zigzag copper-clad plate 6 and 7 welded to the TVS tube protection assembly with the bottom of the electrode plug (the other side of the welding bridge wire), and pass through the foot wires 9 and 10 through the metallized via holes 2 and 3 After forming a circuit connection, the circuit connection adopts reflow soldering, manual soldering or coating conductive glue. Since the copper clad laminate is higher than the PCB board, a thin layer of air gap will be formed between the copper clad laminate and the shell 11 to become an electrostatic discharge gap, and the metallization The via holes 2, 3 are welded with the pins 9, 10 to form an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com