Surge absorption tube and manufacturing method thereof

A surge absorbing, ceramic tube technology, used in electrical components, spark gaps, spark plugs, etc., can solve the problems of protection voltage attenuation, glass tube breakage, high cost, and achieve strong surge resistance, fast response speed, and durability. high flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

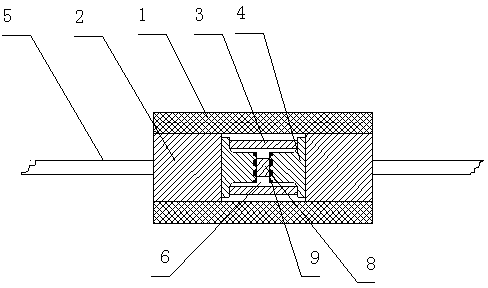

[0032] Example 1 as figure 1 , image 3 As shown: this embodiment is a surge absorber, which combines a ceramic surge absorber and a glass surge absorber, wherein the ceramic surge absorber is set in the middle of the glass surge absorber; Two internal electrodes 4 extend from both ends of the ceramic tube 3 to the middle, and there is a gap 6 for discharge between the two internal electrodes 4; The two sides of the tube 1 extend inwards and are in contact with the two inner electrodes 4 in the ceramic surge absorbing tube, and the space inside the glass outer tube 1 is filled with an inert gas.

[0033] Such as figure 1 , 3 As shown, it includes a glass outer tube 1, two sealing electrode columns 2, one is the first sealing electrode column 2a, the other is the second sealing electrode column 2b, a ceramic tube 3, two internal electrodes 4, the first Internal electrode 4a, second internal electrode 4b, first lead wire 5a, second lead wire 5b, air gap 6, chip 7, conductive...

Embodiment 2

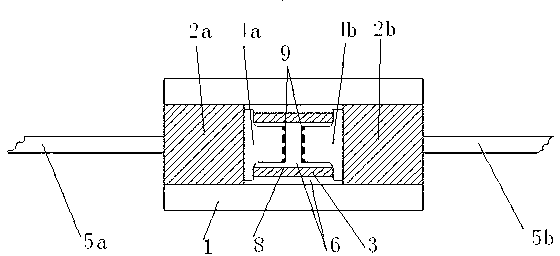

[0045] Example 2, such as figure 2 As shown, in this example, the wafer 7 is removed, and the width precision of the air gap 6 is controlled by controlling the length precision of the ceramic inner tube 3 and the length precision of the first internal electrode 4a and the second internal electrode 4b. The production method is the same as Example 1.

Embodiment 3

[0046] Example 3, such as Figure 4 , Figure 5 As shown, in this example, the first lead 5a and the second lead 5b are removed to realize the surface mount product of the present invention. This design requires the first sealing electrode 2a and the second sealing electrode 2b to be connected from After the bar is processed and cut, it needs to be formed by stamping Figure 6 , Figure 7 Shape, except that the sealing mold and embodiment 1 lack the pressure die, all the other structure manufacturing methods are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com