Gauge for radial run-out of inner bore walls at two ends of hollow shaft

A technology of radial runout and inner hole wall, which is applied in the direction of measuring devices, instruments, and mechanical devices, can solve the problems that restrict the industrialization process of high-precision parts and achieve the effect of convenient measurement, simple structure and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In the following, the present invention will be further explained based on the drawings and the embodiments.

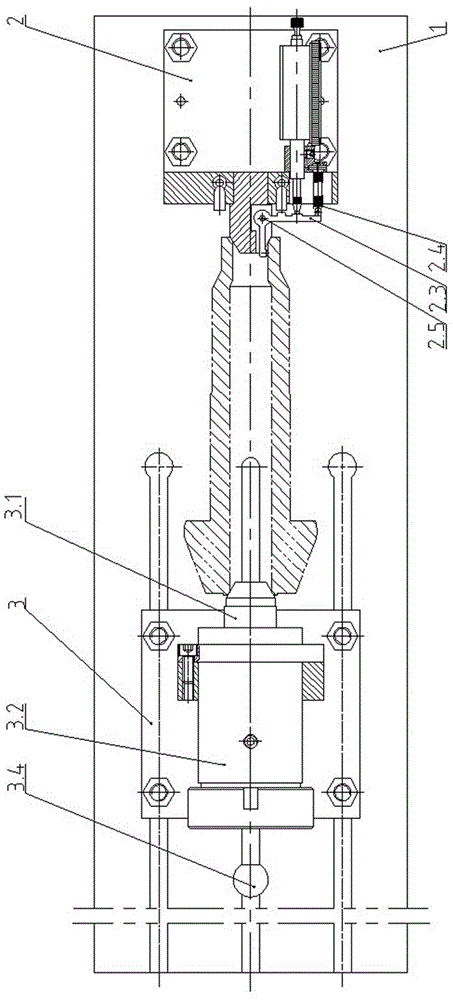

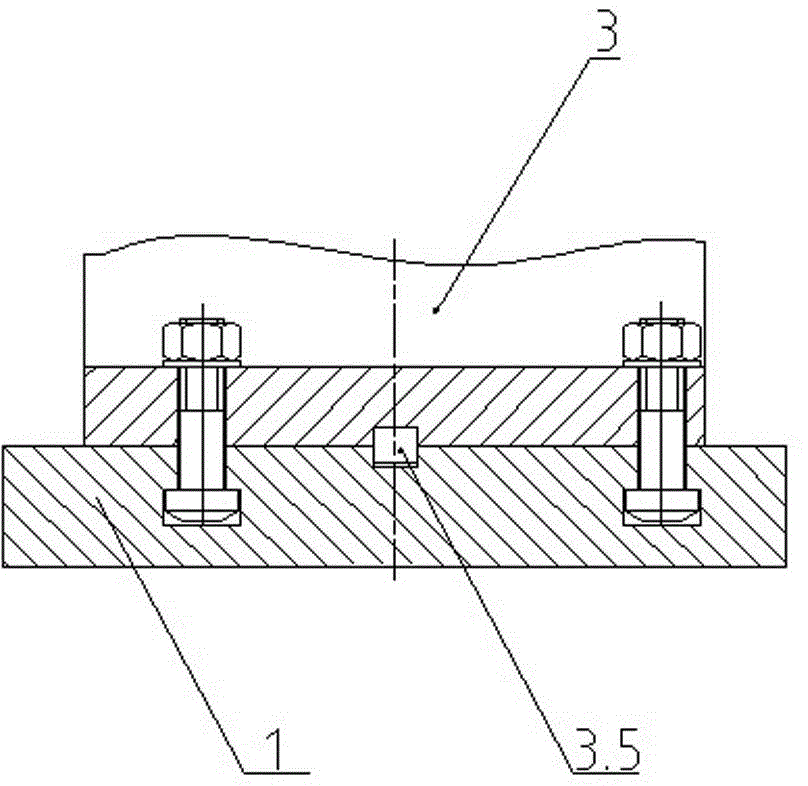

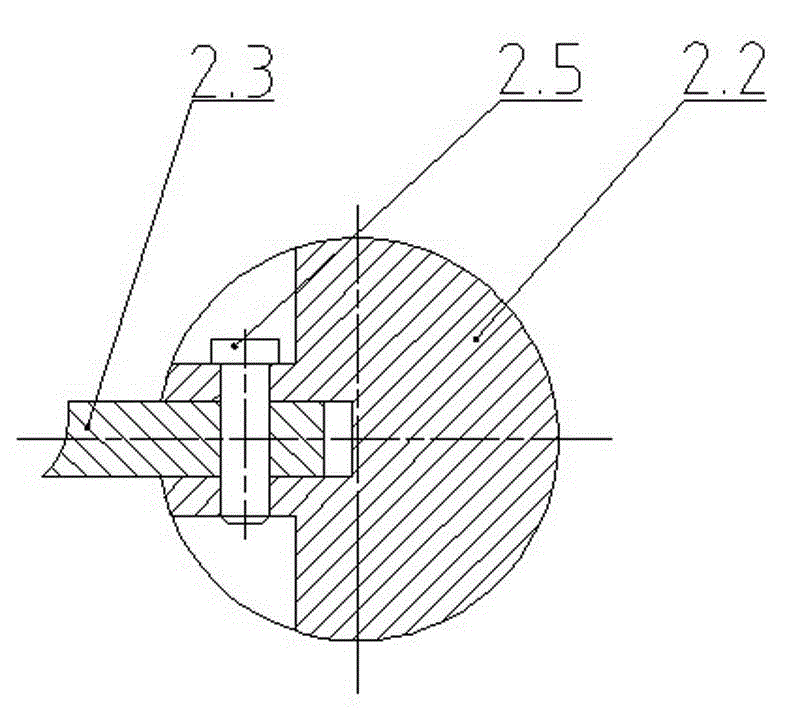

[0015] figure 1 The shown test tool for radial runout of the inner hole wall at both ends of the hollow shaft includes a base 1, a fixed bracket 2 and a movable bracket 3. This embodiment is used for detecting the radial runout of the inner hole wall at both ends of the transmission shaft of a car transmission. The base 1 is a rectangular plate, one end in the length direction of the plate surface is fixedly connected to the fixed support 2, and the other end is evenly distributed with three parallel and upwardly opening longitudinal grooves. The groove in the middle is a rectangular groove, and the T-shaped grooves are arranged on both sides. The slot is used to lock the movable bracket 3. The movable bracket 3 is an angular member, and a rectangular strip 3.5 protruding downward is provided at the bottom. The rectangular strip 3.5 cooperates with the groove in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com